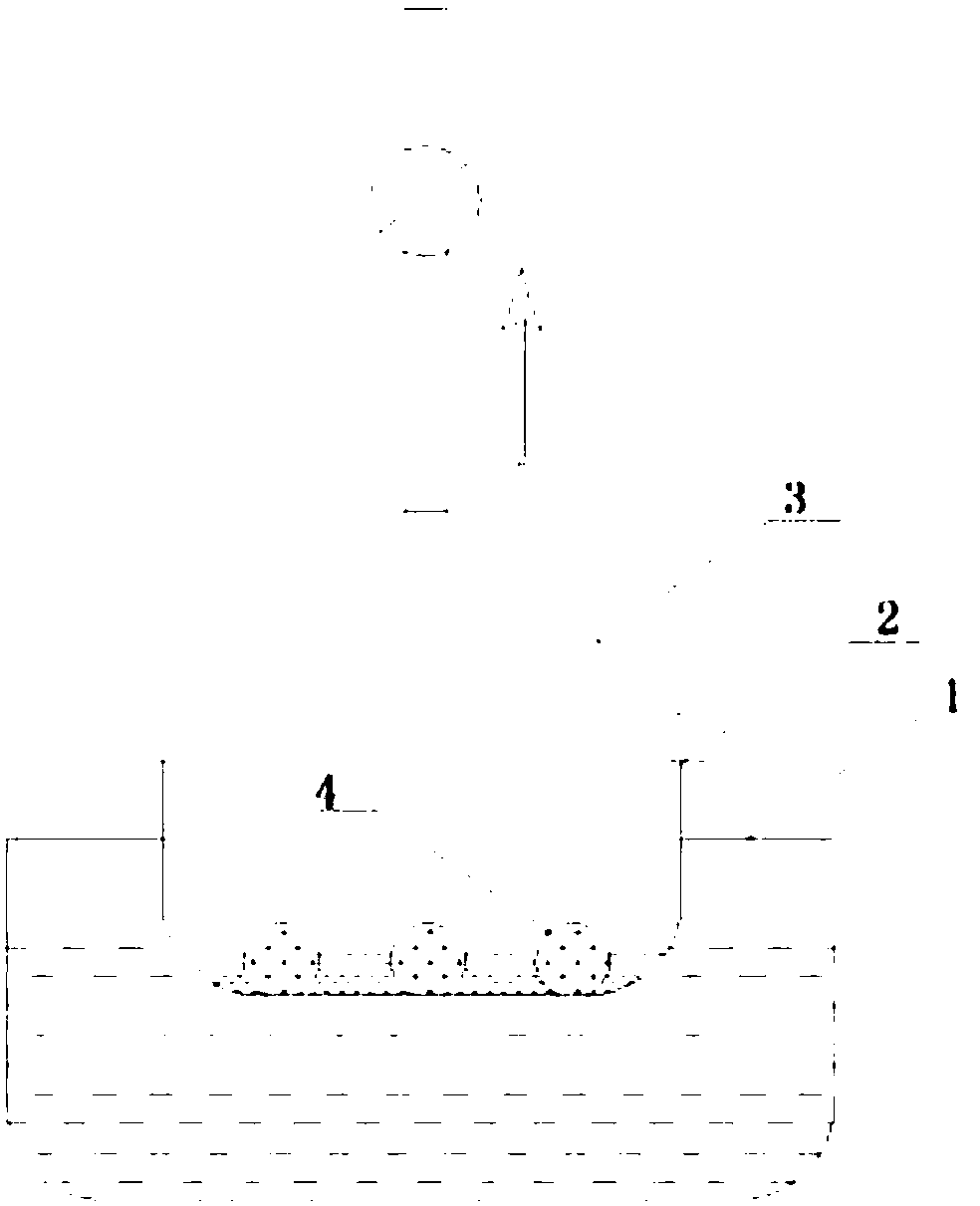

Explosive recrystallization preparation method and device for explosive crystallization

A technology of recrystallization and explosives, applied in explosives processing equipment, explosives, offensive equipment and other directions, can solve the problems of low recrystallization efficiency of explosives, poor quality consistency, etc., to solve the problem of production bottleneck, reduce impact sensitivity, and accurately control temperature and temperature. The effect of evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

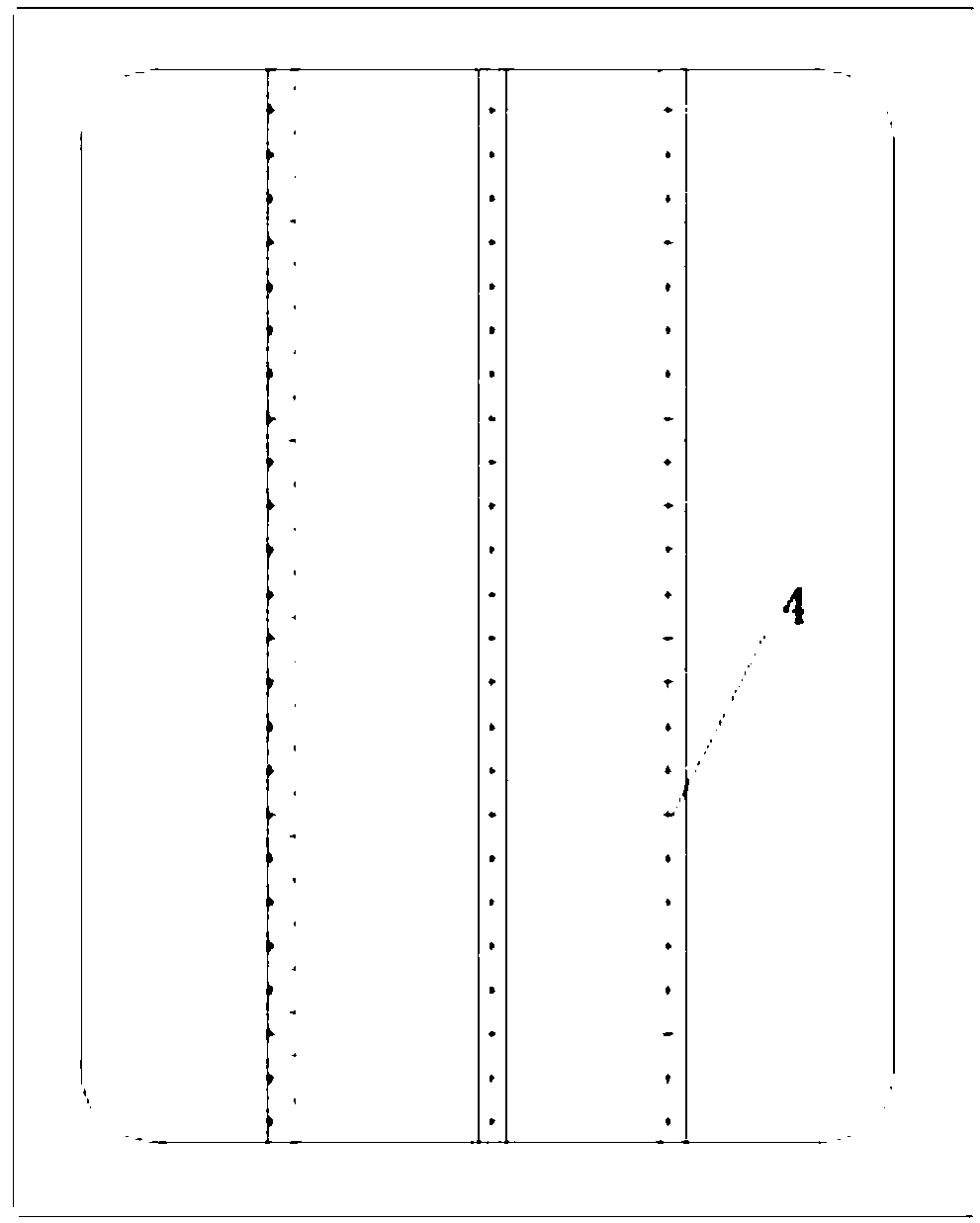

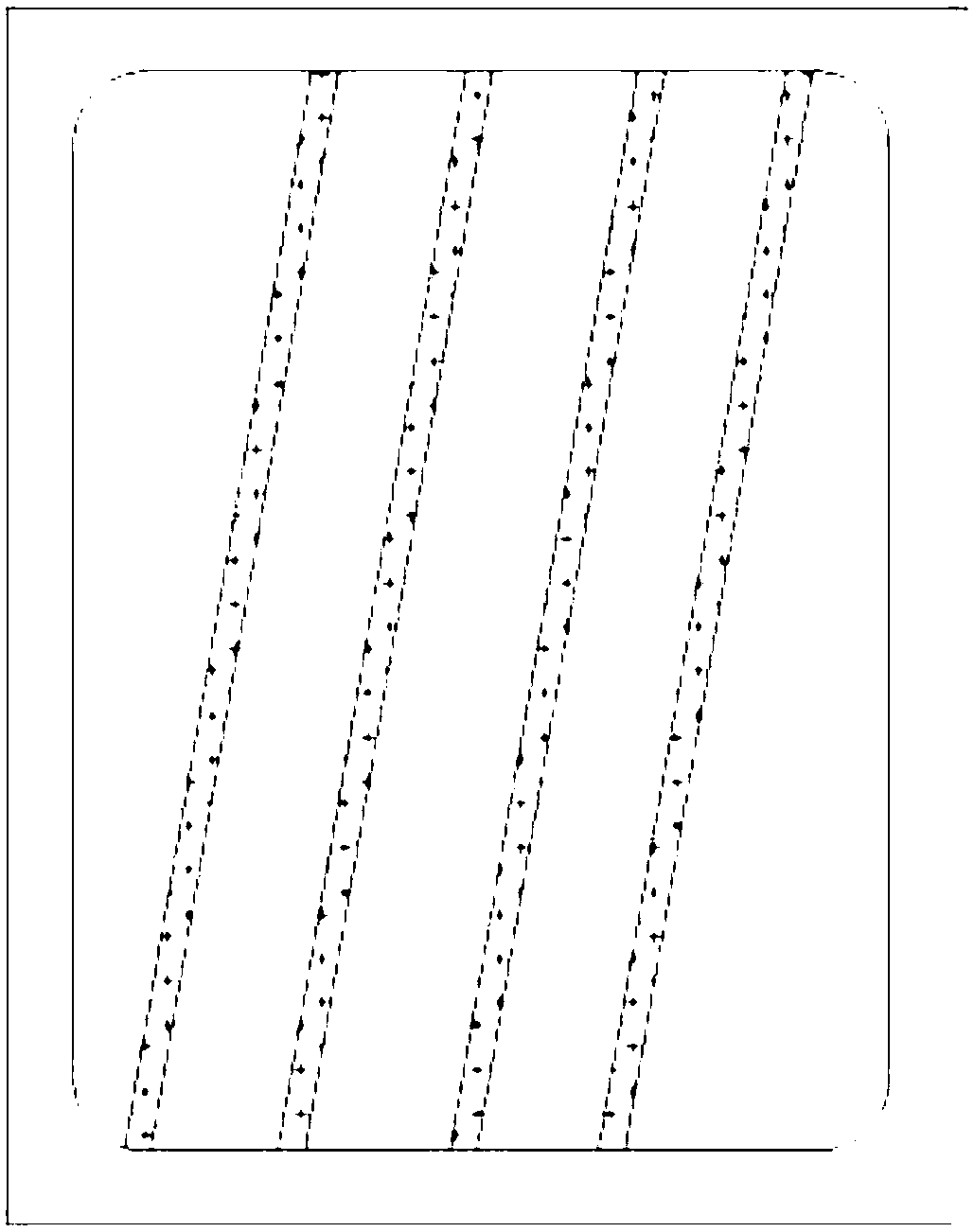

Method used

Image

Examples

Embodiment 1

[0035] (1) The explosive is completely dissolved in an acetone solvent to obtain the explosive stock solution;

[0036] (2) Pour the explosive stock solution into the grid crystallization tray, then put the grid crystallization tray into the precision constant temperature heating water tank, raise the temperature of the precision constant temperature heating water tank to 60°C and keep the constant temperature;

[0037] (3) Turn on the top ventilation system located directly above the grid crystallization plate to continuously draw air upwards, and keep the ventilation speed stable at 0.75m / s. During this process, the solvent evaporates continuously and the explosive crystallizes continuously until all the solvent evaporates and the explosive crystallizes completely So far, the qualified rate of crystal is 98.5%.

Embodiment 2

[0039] (1) The explosive is completely dissolved in an acetone solvent to obtain the explosive stock solution;

[0040] (2) Pour the explosive stock solution into the grid crystallization tray, then put the grid crystallization tray into the precision constant temperature heating water tank, raise the temperature of the precision constant temperature heating water tank to 59°C and keep the constant temperature;

[0041] (3) Turn on the top ventilation system located directly above the grid crystallization tray to continuously draw air upwards, and keep the ventilation speed stable at 0.77m / s. During this process, the solvent evaporates continuously and the explosive crystallizes continuously until all the solvent evaporates and the explosive crystallizes completely So far, the qualified rate of crystal is 98%.

Embodiment 3

[0043] (1) The explosive is completely dissolved in an acetone solvent to obtain the explosive stock solution;

[0044] (2) Pour the explosive stock solution into the grid crystallization tray, then put the grid crystallization tray into the precision constant temperature heating water tank, raise the temperature of the precision constant temperature heating water tank to 61°C and keep the constant temperature;

[0045] (3) Turn on the top ventilation system located directly above the grid crystallization tray to continuously draw air upwards, and keep the ventilation speed stable at 0.73m / s. During this process, the solvent evaporates continuously and the explosive crystallizes continuously until all the solvent evaporates and the explosive crystallizes completely So far, the qualified rate of crystal is 98%.

[0046]According to the test method of GJB772A-97 (601.1), the recrystallized explosive of the present invention was tested for impact sensitivity. In the experiment, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com