Method for performing heat treatment on sensitized explosive

A technology for sensitizing explosives and heat treatment temperature, applied in explosives, explosives processing equipment, offensive equipment, etc., can solve problems such as dead pressure, easy degradation, poor stability, etc., and achieve improved detonation sensitivity, simple operation steps, impact sensitivity and friction Effect of Sensitivity Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] FOX-7 explosive sensitization test:

[0022] Step 1: Weigh 5g of explosive FOX-7 and put it into KSL-1100X box-type muffle furnace;

[0023] Step 2: Check the TG-DTA thermal property curve of explosive FOX-7, determine its initial decomposition temperature at 220°C, set the muffle furnace to heat to 220°C, and keep it warm for 1 hour;

[0024] Step 3: After naturally cooling down to room temperature, porous self-sensitized FOX-7 is obtained.

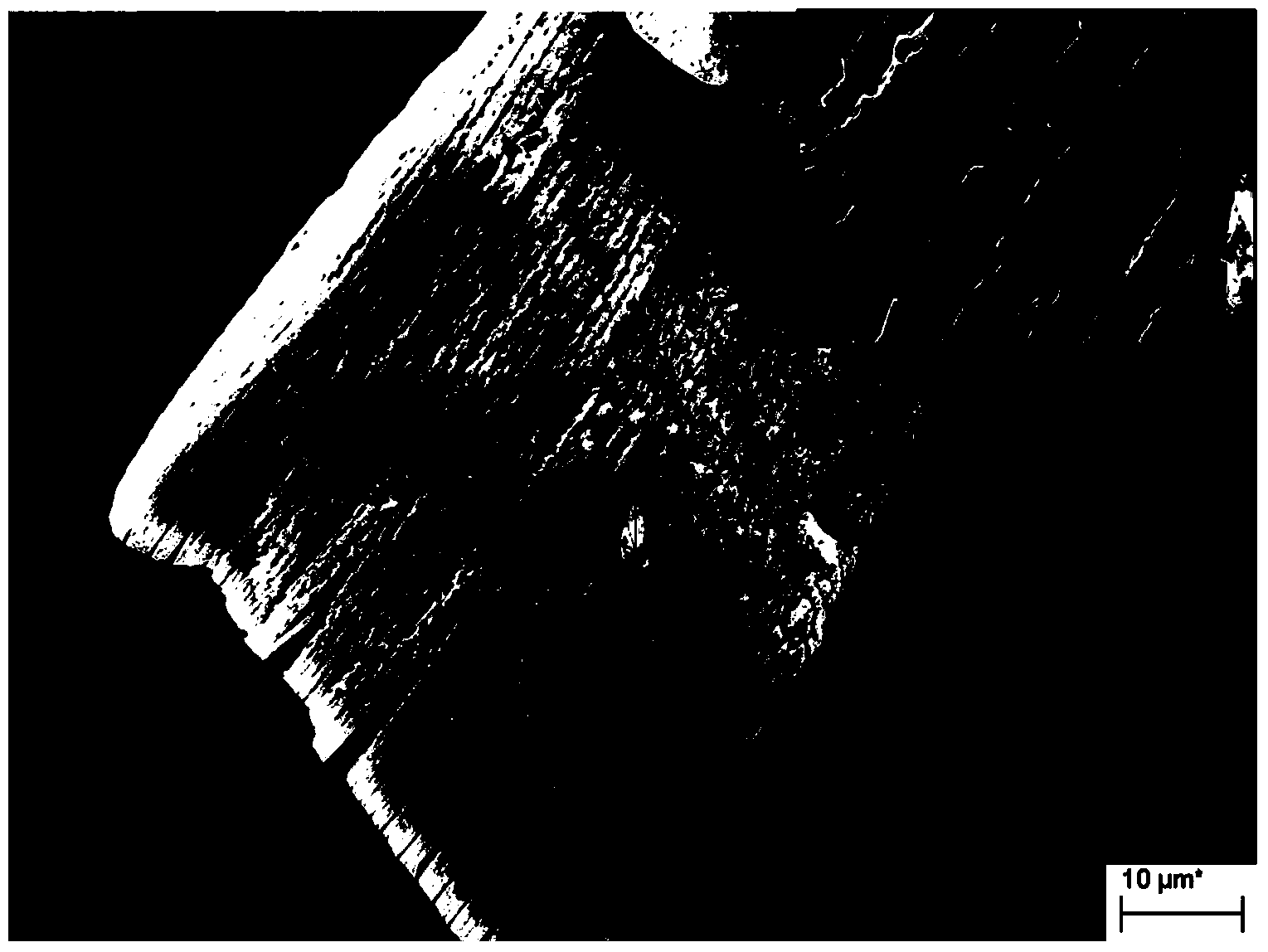

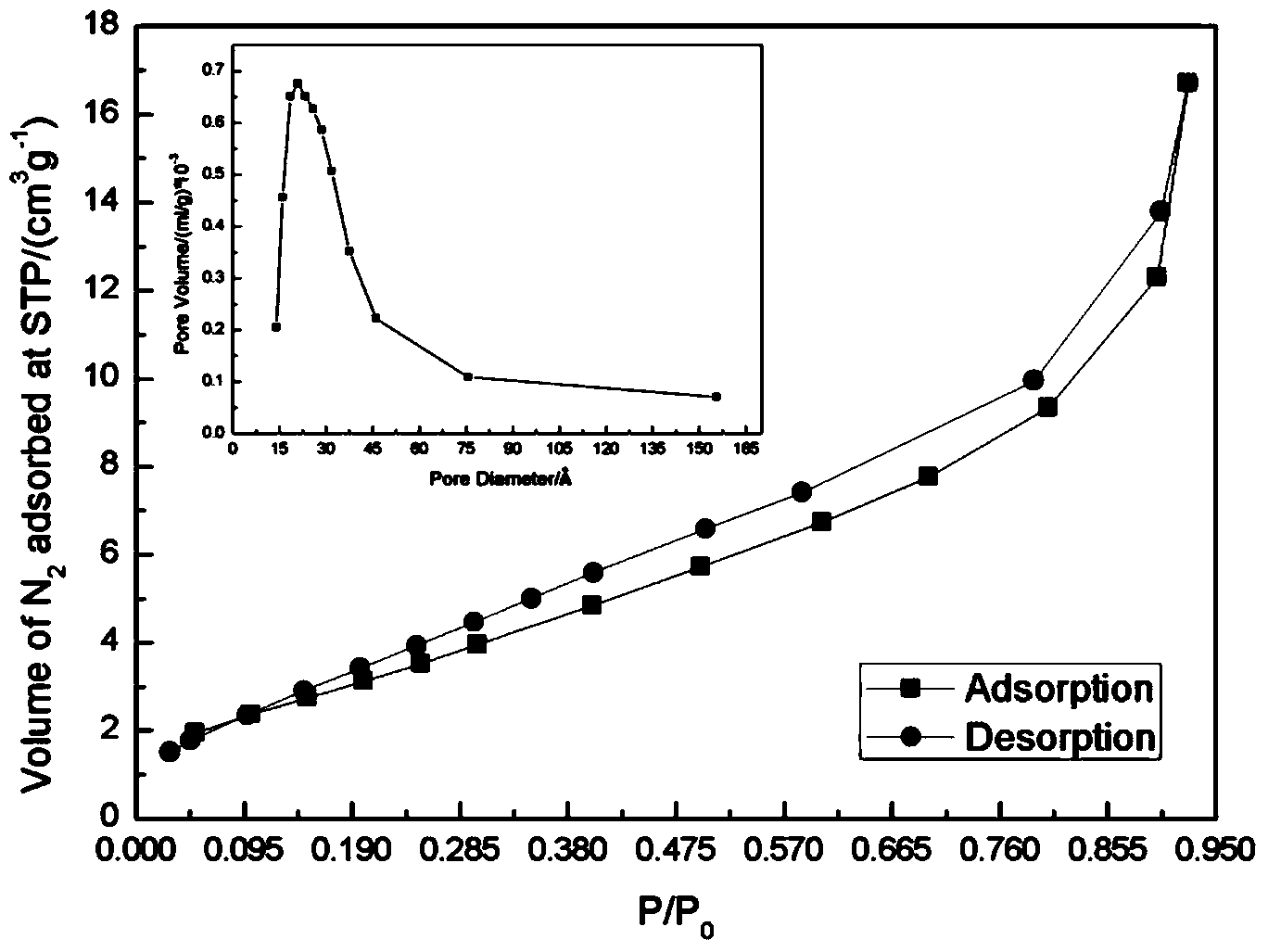

[0025] Depend on figure 1 and figure 2 It can be seen from the comparison that compared with ordinary FOX-7, the sensitized FOX-7 explosive crystals have obvious porous structure. Depend on image 3 N 2 It can be seen from the adsorption-desorption curve that the self-sensitized FOX-7 explosive has a mesoporous structure of 2.0-5.0 nanometers, and the measured specific surface area is 6.754m 2 / g, about the specific surface area of expanded ammonium nitrate (0.33m 2 / g) 20 times. It can be confirmed from the data in Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com