Environment-friendly and low-cost plastic film packaging colloidal emulsion explosive and preparation method thereof

An emulsion explosive, low-cost technology, used in explosives processing equipment, explosives, offensive equipment and other directions, can solve the problems of safety hazards in blasting construction sites, incomplete explosion of explosives, unexploded explosives, etc., to achieve excellent explosive performance and improve explosive power. , the effect of reducing the crystallization point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

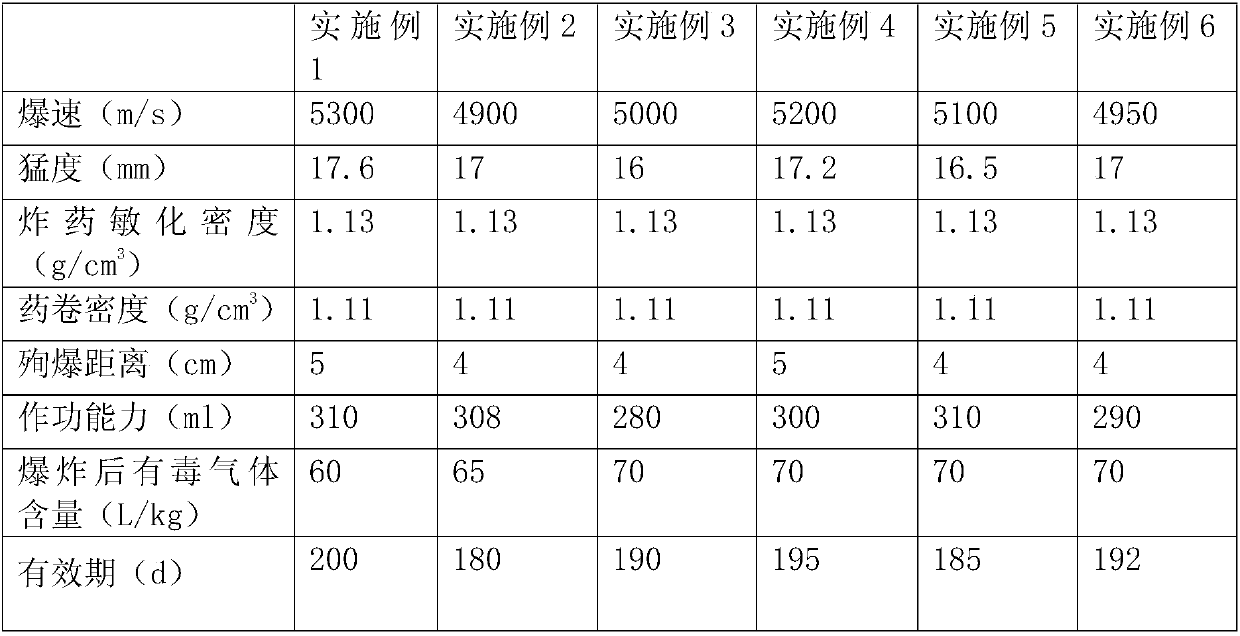

Embodiment 1

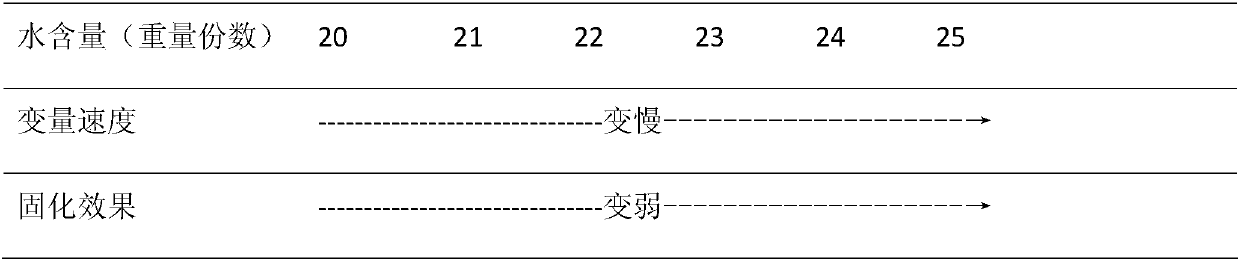

[0051] This embodiment provides an environmentally friendly and low-cost plastic film packaging colloidal emulsion explosive. The emulsion explosive includes the following components in parts by mass:

[0052] Ammonium nitrate: 30 parts, sodium nitrate: 10 parts, paraffin wax: 15 parts, water: 20 parts, emulsifier: 7 parts, emulsification aid: 3 parts, sensitizer: 8 parts, sensitization accelerator: 3 parts, Foaming agent: 7 parts, acetic acid: 1 part, flame suppressant: 3 parts, adhesive: 2 parts;

[0053] The emulsifier is a compound emulsifier, which is a mixture of sorbitan monooleate and succinimide in equal proportions; the emulsification aid is DRQ type emulsification aid; the sensitizer is sodium nitrite; the sensitization accelerator It is phosphoric acid; the foaming agent is dinitrosopentamethylenetetramine; the flame suppressant is a mixture of sodium chloride and potassium chloride; the adhesive is polyurethane;

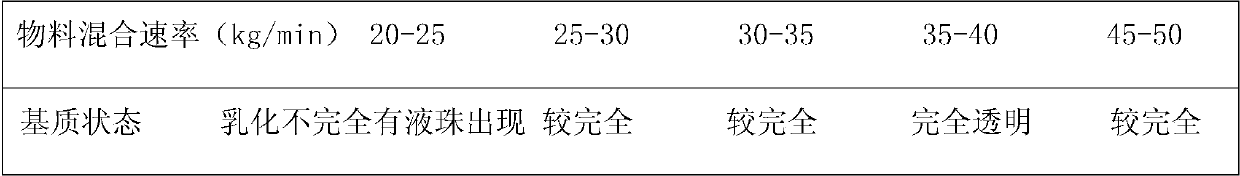

[0054] The preparation method of the above-mentio...

Embodiment 2

[0062] This embodiment provides an environmentally friendly and low-cost plastic film packaging colloidal emulsion explosive. The emulsion explosive includes the following components in parts by mass:

[0063] Ammonium nitrate: 40 parts, sodium nitrate: 15 parts, paraffin wax: 20 parts, water: 25 parts, emulsifier: 9 parts, emulsifying aid: 5 parts, sensitizer: 10 parts, sensitization accelerator: 5 parts, Foaming agent: 9 parts, acetic acid: 1-3 parts, flame suppressant: 5 parts, adhesive: 4 parts.

[0064] The emulsifier is a compound emulsifier, which is a mixture of sorbitan monooleate and succinimide in equal proportions; the emulsification aid is DRQ type emulsification aid; the sensitizer is sodium nitrite; the sensitization accelerator Phosphoric acid; foaming agent is potassium nitrite; flame suppressant is a mixture of sodium chloride and potassium chloride; adhesive is polyurethane;

[0065] The preparation method of environmentally friendly and low-cost plastic fi...

Embodiment 3

[0073] This embodiment provides an environmentally friendly and low-cost plastic film packaging colloidal emulsion explosive. The emulsion explosive includes the following components in parts by mass:

[0074] Ammonium nitrate: 35 parts, sodium nitrate: 13 parts, paraffin wax: 18 parts, water: 22 parts, emulsifier: 8 parts, emulsification aid: 4 parts, sensitizer: 9 parts, sensitization accelerator: 4 parts, Foaming agent: 8 parts, acetic acid: 2 parts, flame suppressant: 4 parts, adhesive: 3 parts.

[0075] The emulsifier is a compound emulsifier, which is a mixture of sorbitan monooleate and succinimide in equal proportions; the emulsification aid is DRQ type emulsification aid; the sensitizer is sodium nitrite; the sensitization accelerator It is phosphoric acid; the foaming agent is dinitrosopentamethylenetetramine or potassium nitrite; the flame suppressant is a mixture of sodium chloride and potassium chloride; the adhesive is polyurethane;

[0076] The preparation meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com