Electric sintering furnace

A sintering furnace, electric heating technology, applied in the direction of furnace, furnace type, waste heat treatment, etc., can solve the problem of incomplete combustion of trace waste gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The following describes in detail how the structure of the present invention is combined and used in conjunction with the attached diagrams, and it should be easier to understand the purpose, technical content, characteristics and effects of the present invention.

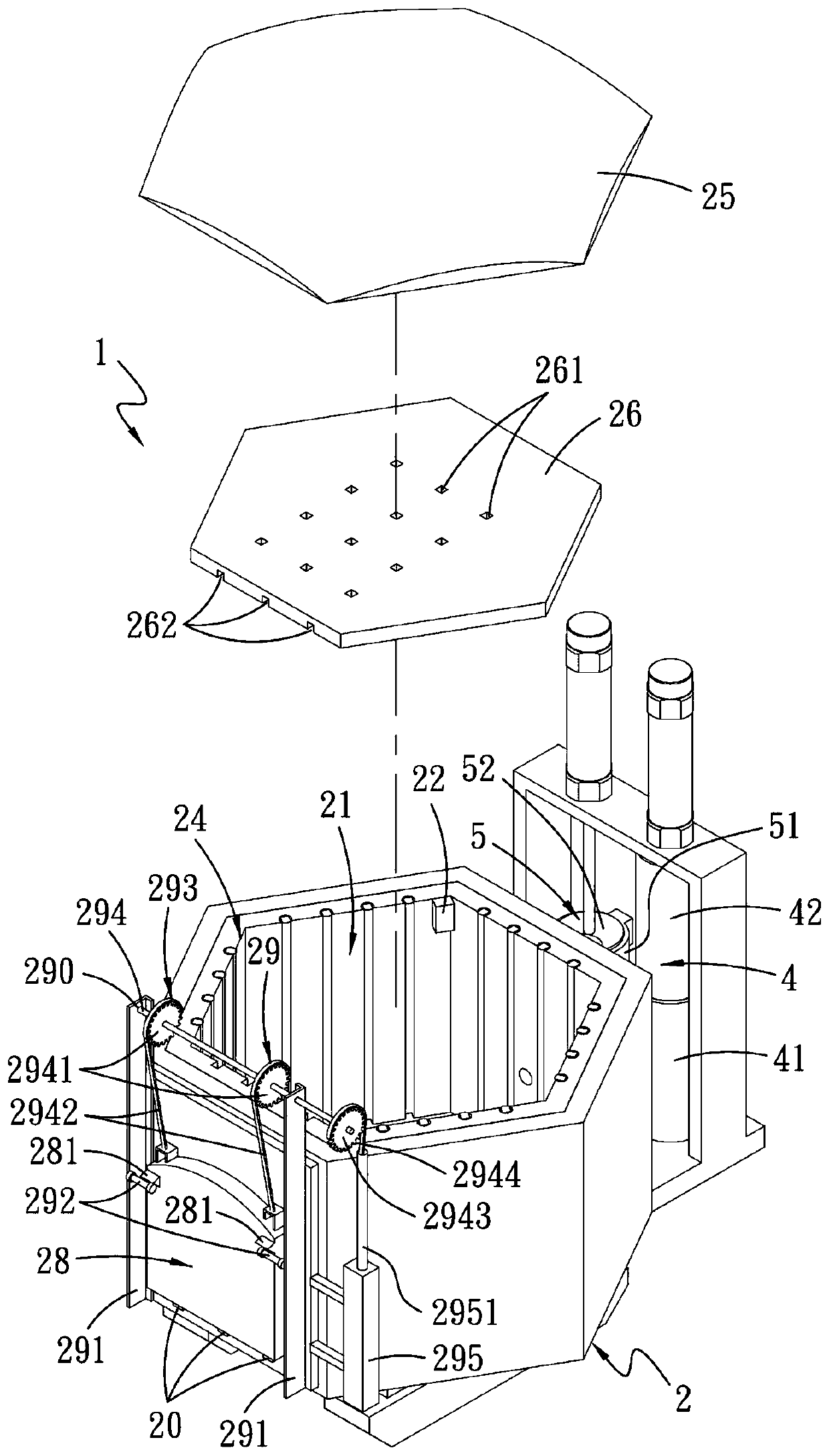

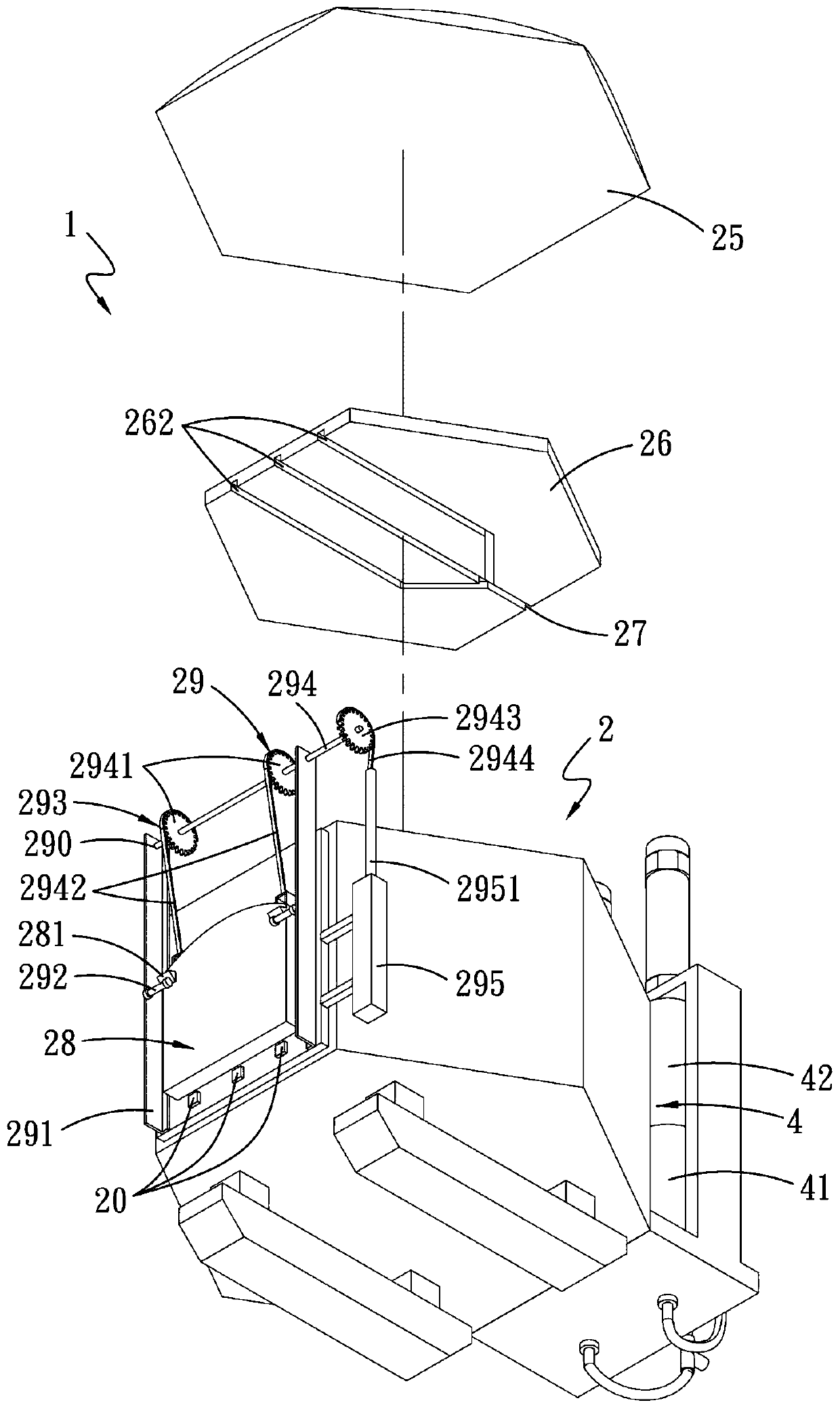

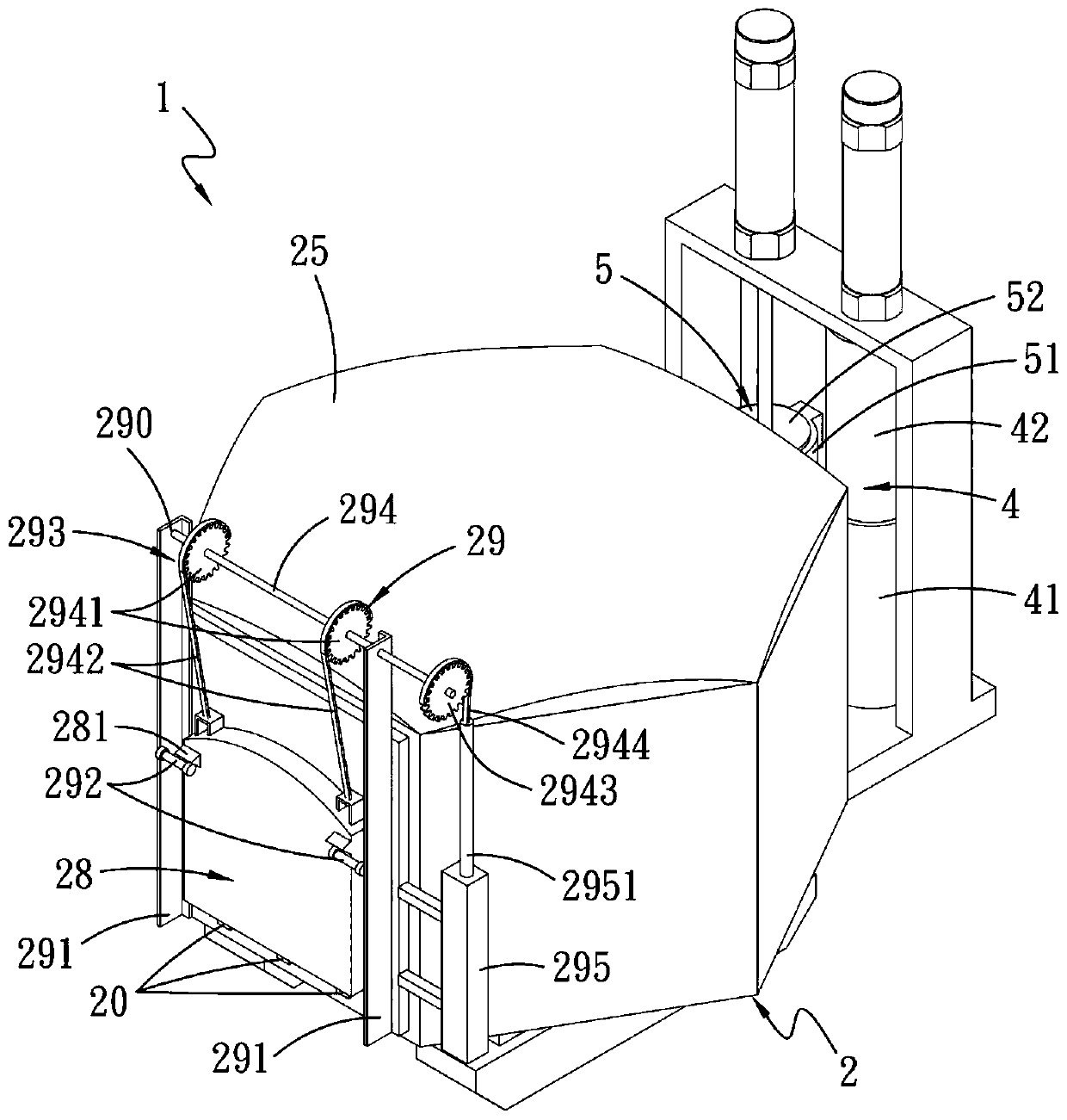

[0056] An electric heating sintering furnace of the present invention, please refer to figure 1 , 2 and image 3 , 4 As shown, the electrothermal sintering furnace 1 includes a furnace body 2, a circulation barrel 3 arranged behind the furnace body 2, and an exhaust gas pumping device 4 and an air pumping device 5 arranged on both sides of the circulation barrel 3.

[0057] Please refer to figure 1 , 2 and image 3 , 4 and cooperate Figure 5 As shown, the interior of the furnace body 2 is a sintering chamber 21 for placing the shell mold 6. The sintering chamber 21 has a sensor 22 inside. The sensor 22 is used to detect the electrothermal sintering shell inside the sintering chamber 21. After the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com