Smoke inlet device of incinerator

A technology for incinerators and flue gas, applied in the field of flue gas import devices, to achieve the effects of prolonging residence time, low cost, and increasing the number of cycles of convective exchanges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

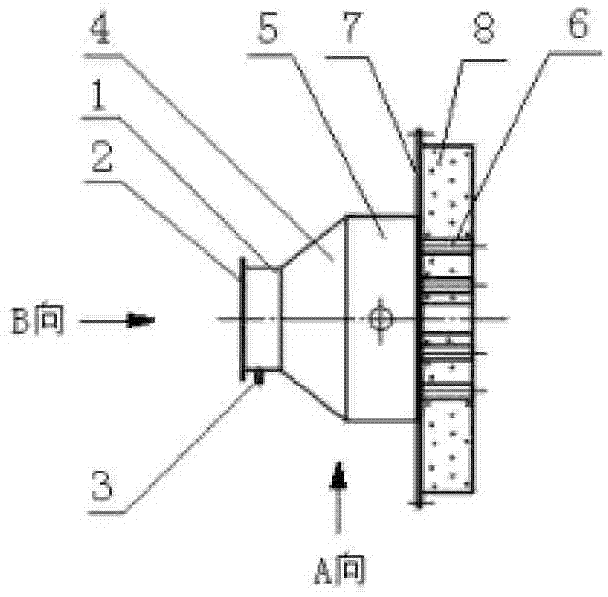

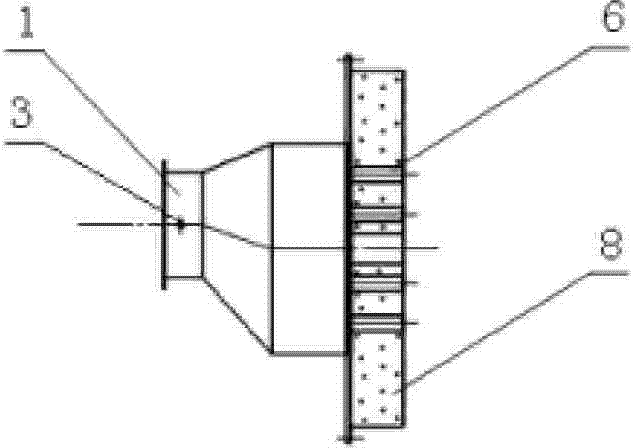

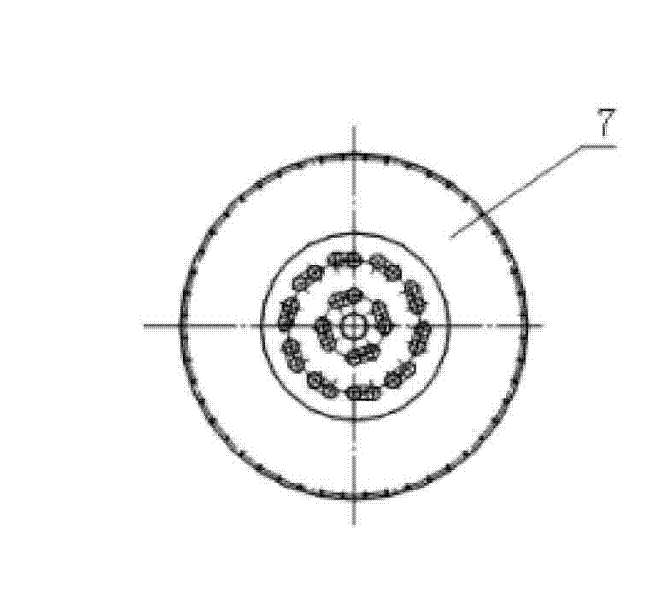

[0012] Embodiments of the present invention: as figure 1 As shown, it consists of flue gas inlet pipe 1, flue gas inlet connecting flange 2, flue gas inlet monitoring pipe 3, flue gas special-shaped pipe 4, flue gas pipe 5, flue gas inlet piping 6, and piping flange 7. The gas inlet connection flange 2 is welded on the port of the flue gas inlet pipe 1, the flue gas inlet monitoring pipe 3 is welded on the side wall of the flue gas inlet pipe 1, the flue gas inlet pipe 1 and the flue gas special-shaped pipe 4, the flue gas pipe 5. The piping flanges 7 are welded together in turn. The flue gas inlet piping 6 is divided into inner and outer circles at the center point, and welded (or bolted) on the piping flange 7 in a double ring shape, and then refractory castables are used. 8. Pouring the flue gas inlet pipe 6 and the pipe flange 7 into one. In order to make the incoming flue gas form a circular vortex shape, one end of the flue gas inlet pipe 6 is welded to the pipe flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com