Excess temperature protector for driving motor of electric automobile

A technology for driving motors and electric vehicles. It is applied in the direction of emergency protection circuit devices and electrical components. It can solve the problems of motor overheating, limited temperature points for detection, and difficult temperature detection, so as to improve reliability, accurately judge, and prevent The effect of overheating damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

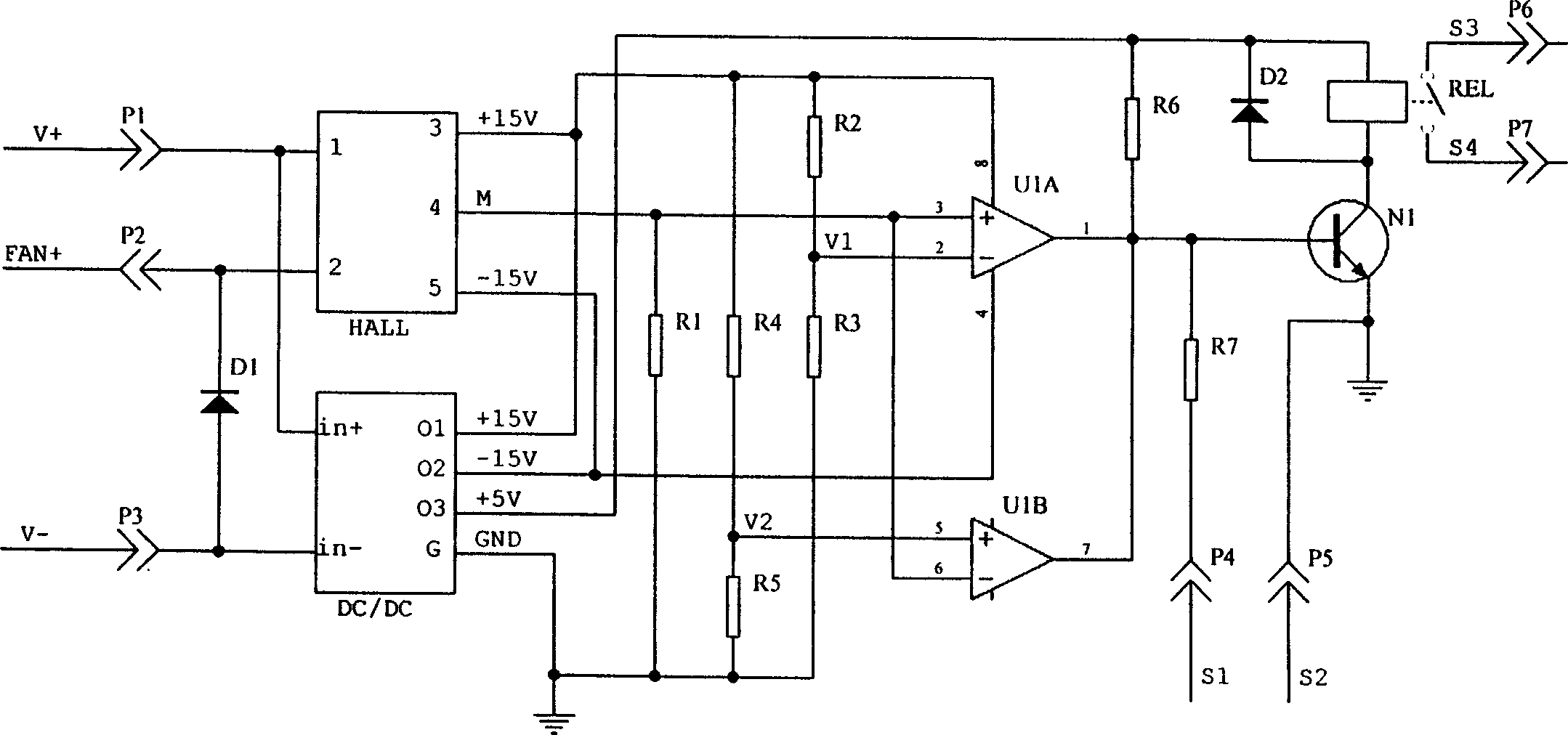

[0009] In the circuit shown in the attached figure, for a drive motor over-temperature protector of an air-cooled DC motor drive system used in an electric bus, the low-voltage DC power supply on the vehicle is 24V, and the DC / DC converter DC / DC selects the model It is the power module of WR24S5D15, the Hall current sensor HALL is a Q20A-10mA magnetic balance sensor, R1 is 2K, U1A and U1B are two comparators on the LM2903 integrated comparator, due to the normal operating current lower limit of the driving motor cooling fan The value and upper limit are 6A and 10.2A respectively, the corresponding R2, R3, R4 and R5 values are 3K, 2K, 2.4K and 5.1K respectively, the obtained undercurrent reference voltage V1 is 6V, overcurrent The reference voltage V2 is 10.2V, R6 is 5.1K, the relay REL model is NT90RHC-SDC24, the transistor N1 model is BD237, D1 selects 3A / 100V diode, D2 selects 1A / 100V diode, the thermal relay installed on the drive motor outside the protector It is a norma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com