Destructive distillation method and device for fluidized bed of oil shale

An oil shale and fluidized bed technology, which is applied in the field of oil shale dry distillation, can solve the problems of easy over-temperature damage of the charcoal burner, difficult to control the charcoal burning temperature, and high charcoal burning load, so as to ensure long-term operation, and the charcoal burning The effect of high efficiency and strong charcoal burning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

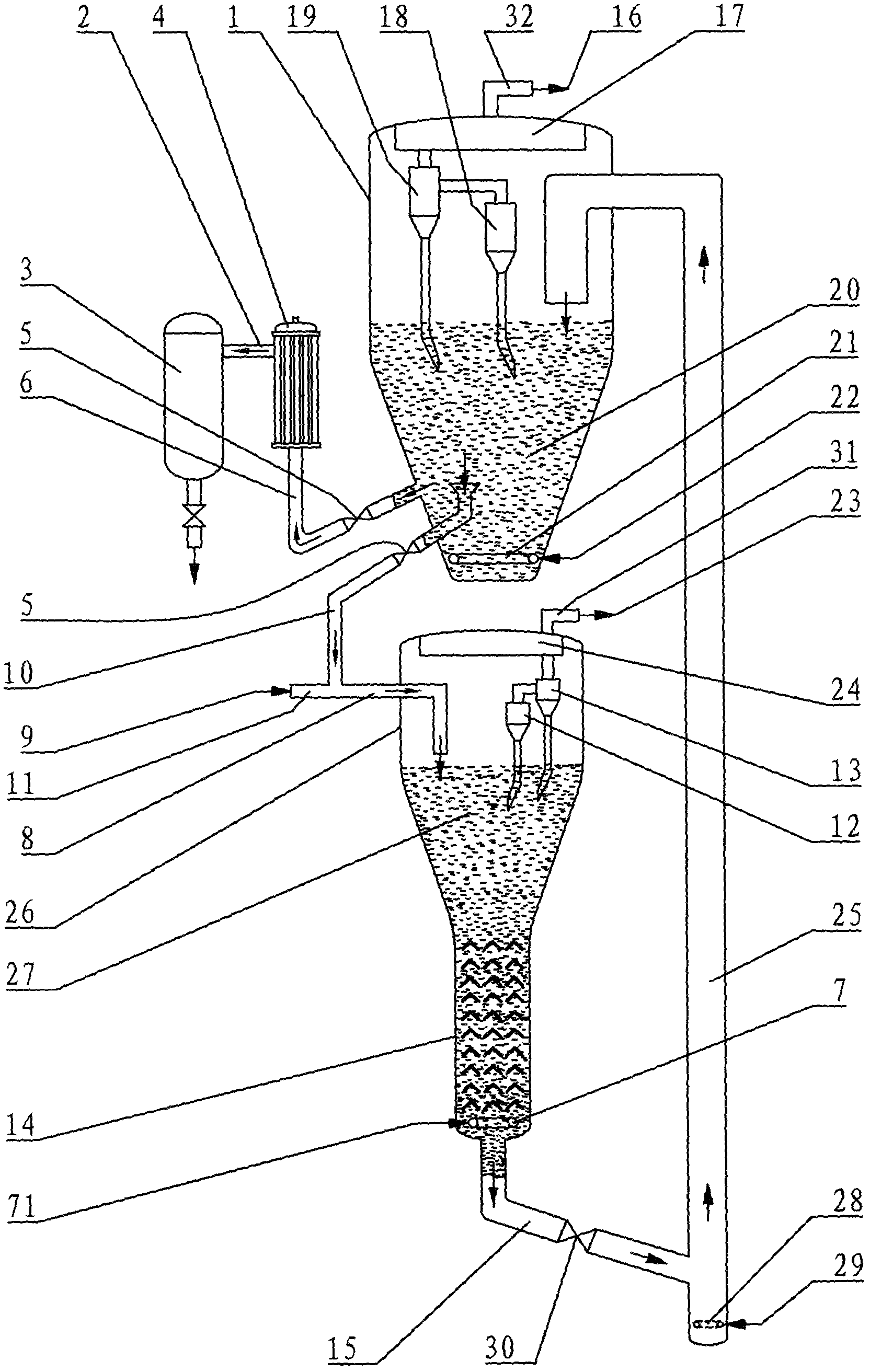

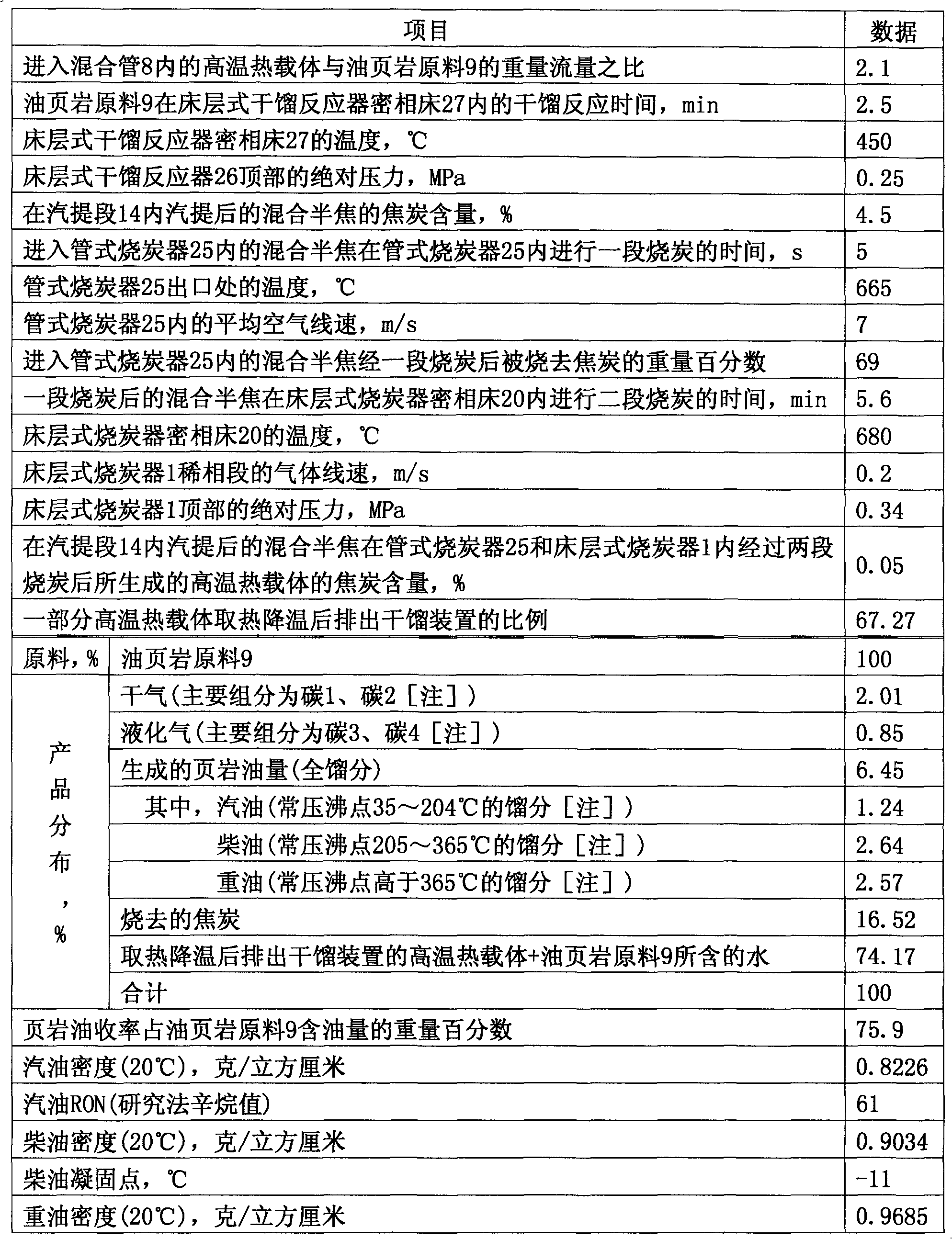

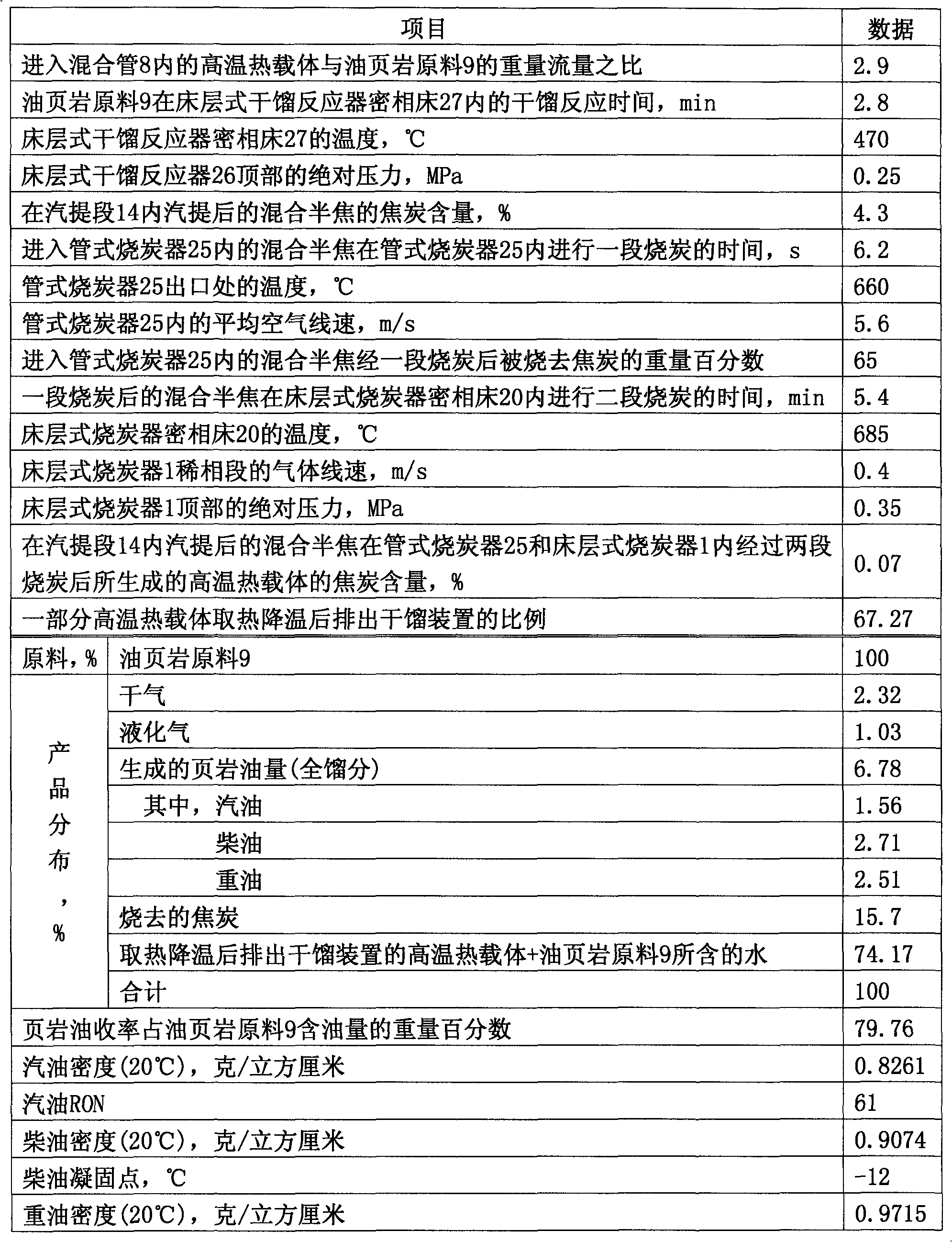

[0049] exist figure 1 On the small-scale test device of the fluidized bed carbonization device shown, 7 groups of tests (Example 1 to Example 7) were carried out according to the steps of the oil shale carbonization method described in the specific embodiment section of this specification. The oil shale raw material 9 is made of Ylang-ylang oil shale powder grain raw material, and its properties are shown in Table 1; the feed rate (the weight flow rate of the oil shale raw material 9 entering the oil shale raw material feed pipe 11) is 150kg / day.

[0050] In Examples 1 to 7, the gas linear velocity in the dilute phase section of the bed-type dry distillation reactor 26 is all 0.6 m / s. The temperature of the mixed semi-coke bed in the stripping section 14 is 500°C, and the stripping medium is the stripping steam 71 at 500°C. The high-temperature heat carrier that enters the heat collector 4 through the high-temperature heat carrier discharge pipe 6 is cooled to 100° C. by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com