Powder coal dry distillation method and device

A technology of pulverized coal and dry distillation, which is applied in special forms of dry distillation, direct heating dry distillation, petroleum industry, etc. Effects of Dosage and Circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

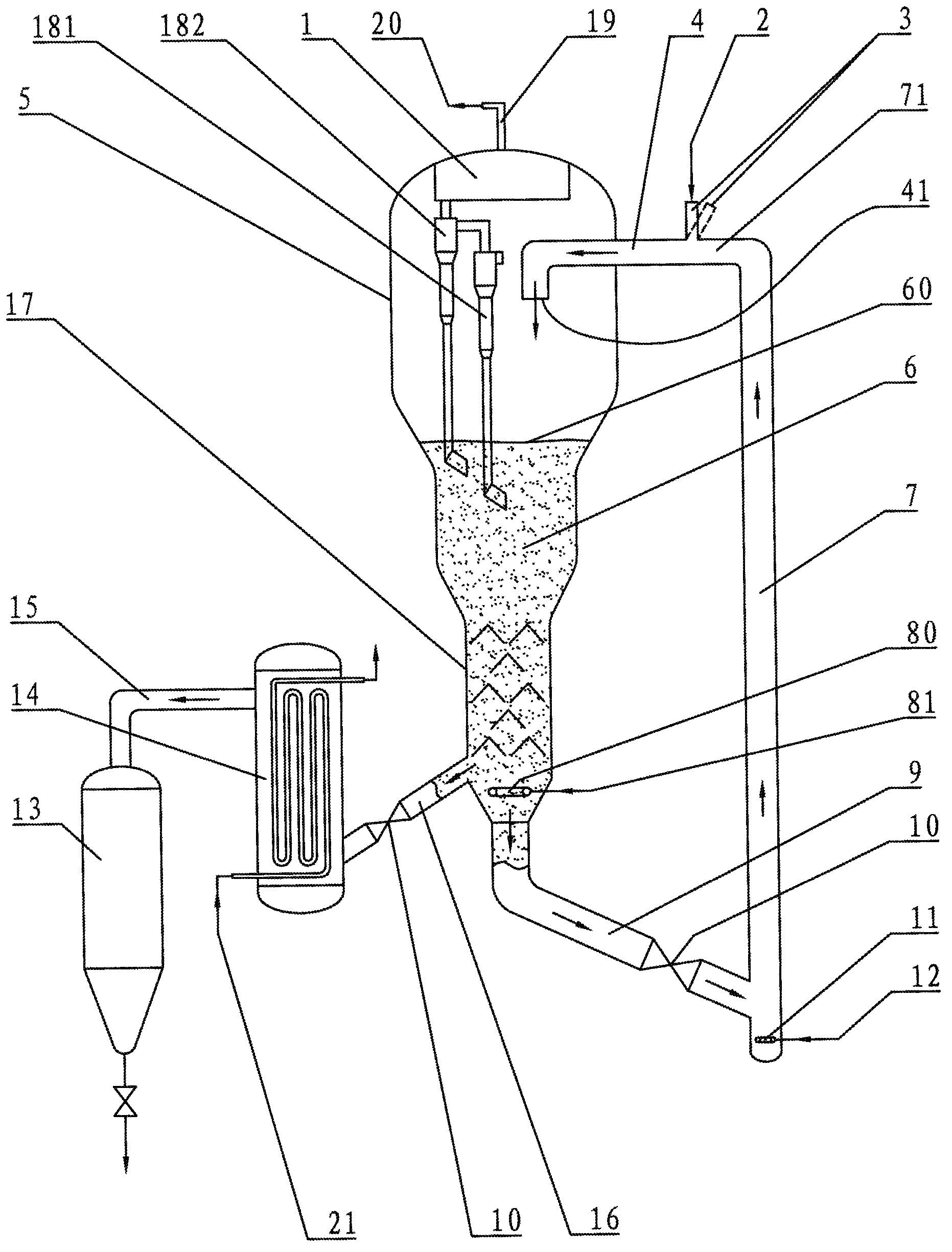

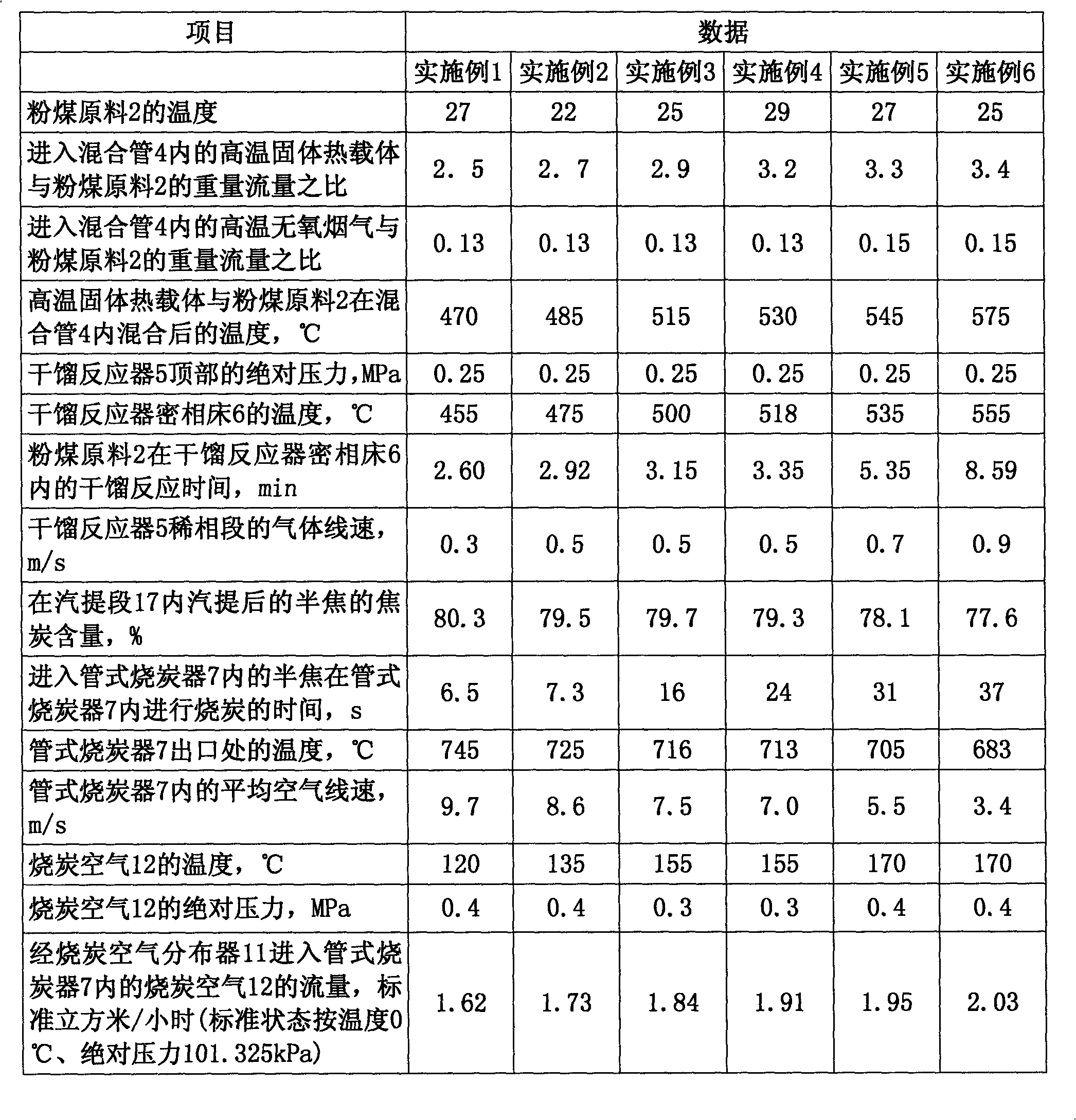

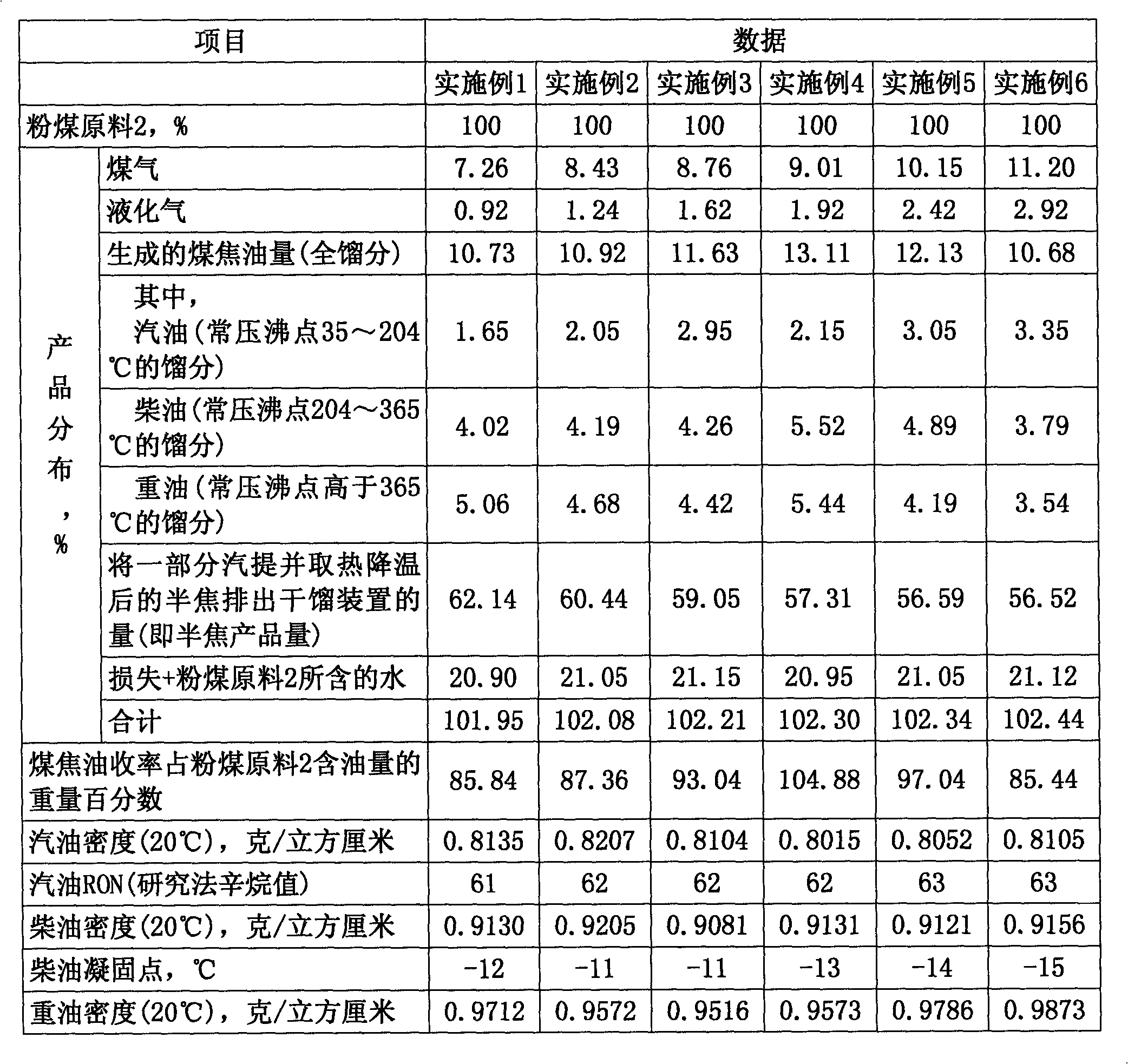

[0049] exist figure 1 On the small-scale test device of the pulverized coal carbonization device shown, 6 groups of tests (Example 1-Example 6) were carried out according to the steps of the pulverized coal carbonization method described in the specific implementation mode of this specification. The pulverized coal raw material 2 is Yima pulverized coal raw material, and its properties are shown in Table 1; the feed rate (the weight flow rate of the pulverized coal raw material 2 entering the pulverized coal raw material feed pipe 3) is 3kg / h (3 kg / hour).

[0050] In Examples 1 to 6, the temperature of the semi-coke bed in the stripping section 17 is 500°C, and the stripping medium is the stripping steam 81 at 500°C. The stripped semi-coke that enters the heat extractor 14 through the semi-coke discharge pipe 16 is cooled to 80° C. by heat extraction medium (de-salted water at ambient temperature). The absolute pressure at the outlet of the tubular charcoal burner 7 is 0.001-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com