Fluidized bed destructive distillation method and device of pulverized coal

A fluidized bed and dry distillation technology, applied in the field of coal chemical industry, can solve the problems of unsatisfactory charcoal burning effect and large charcoal burning load, and achieve the effect of ensuring long-term operation, strong charcoal burning capacity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

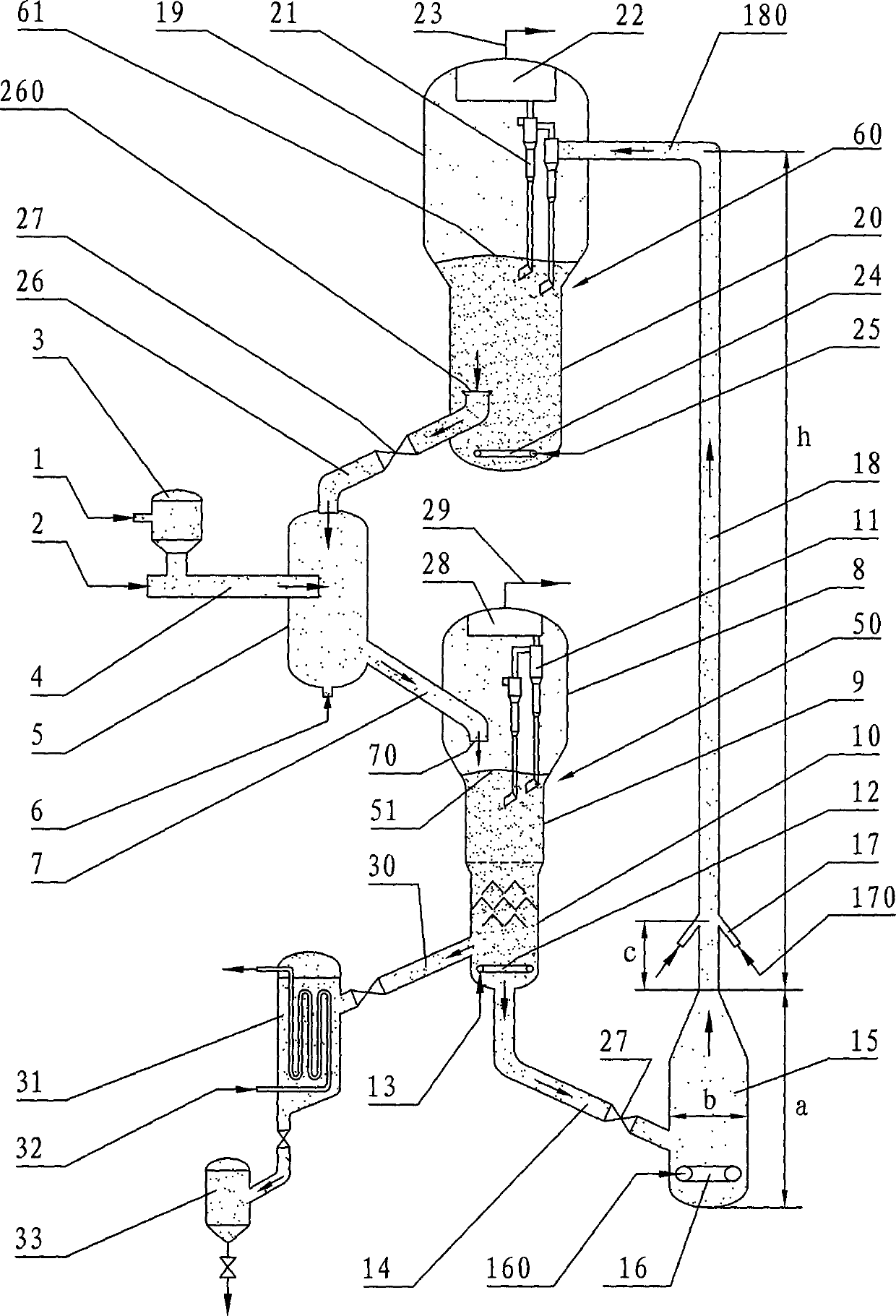

[0014] see figure 1 , the fluidized bed carbonization device of pulverized coal of the present invention (referred to as carbonization device for short) is provided with feeder 3, pulverized coal raw material delivery pipe 4, mixing tank 5, bed type carbonization reactor 50, charcoal burning tank 15, riser burning tube Charcoal device 18, bed type charcoal burner 60. The housing of the mixing tank 5 includes a cylindrical shell through which the pulverized coal raw material delivery pipe 4 passes, and the outlet extends into the mixing tank 5 . The feeder 3 is a metal container with a circular cross section, the bottom of which is connected to the pulverized coal raw material delivery pipe 4 through a pipeline. A loose air duct is provided at the bottom of the mixing tank 5, and a first mixture delivery pipe 7 is provided between the lower part and the bed type dry distillation reactor 50 (the inlet of the first mixture delivery pipe 7 is connected to the lower part of the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com