External repairing internal fixing type polyurea-based dual-wall self-repairing microcapsule and preparation method thereof

A self-healing microcapsule, internal solid technology, applied in microcapsule preparation, microsphere preparation, coating and other directions, can solve the problem of low contact rate between repairing agent and curing agent, achieve excellent physical and chemical properties and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

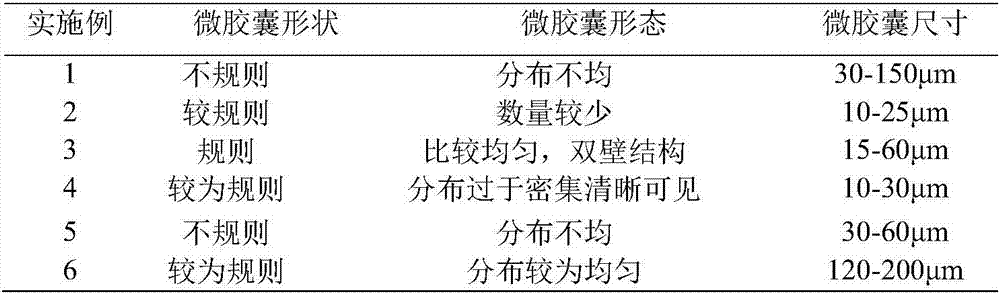

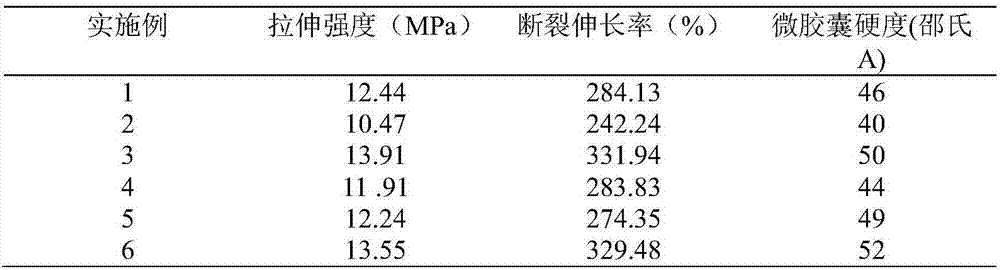

Embodiment 1

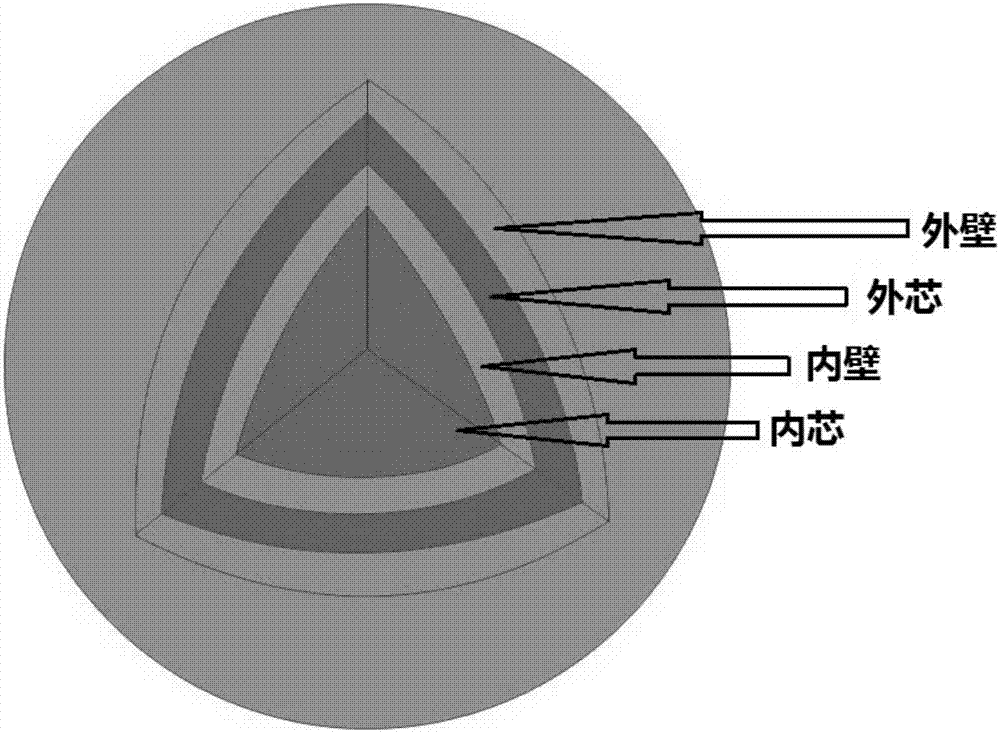

[0028] Externally repaired and internally solid polyurea-based double-walled self-healing microcapsules, including an inner capsule wall and an outer capsule wall; the inner capsule wall is coated with an amine-based chain extender emulsion, and the outer capsule wall is coated with a pre- Polymer emulsion; both the inner capsule wall and the outer capsule wall are polyurea prepared by interfacial polymerization, and the polyurea is coated with the amine-based chain extender emulsion coated by the inner capsule wall and the outer capsule wall The prepolymer emulsion reaction is obtained.

[0029] The preparation method of externally repaired and internally solidified polyurea-based double-wall self-repairing microcapsules comprises the following steps:

[0030] (1) Preparation of prepolymer emulsion: aliphatic isocyanate repair agent isophorone diisocyanate (IPDI) and amino-terminated polyether polyetheramine D400 are mixed uniformly according to a mass ratio of 1:1 to obtain ...

Embodiment 2

[0039] Different from Example 1,

[0040] The preparation method of externally repaired and internally solidified polyurea-based double-wall self-repairing microcapsules comprises the following steps:

[0041] (1) Preparation of prepolymer emulsion: aliphatic isocyanate repair agent 1,4-cyclohexane diisocyanate and amino-terminated polyether 3,5-dimethylthiotoluene-2,6-diamine according to 1: Mix evenly with a mass ratio of 2 to obtain a prepolymer; stir evenly at a rotating speed of 2000rmp, add an emulsifier and a solvent, and heat at 68°C for 2-3h at a rotating speed of 2300rpm to obtain a prepolymer emulsion; the emulsifier The amount is 9% of the mass of the prepolymer, and the mass ratio of the emulsifier to the solvent is 1:154.

[0042] (2) Preparation of amine-based chain extender emulsion: take an appropriate amount of emulsifier and solvent, stir at a speed of 1000rmp until mixed evenly; the mass ratio of the emulsifier and solvent is 1:46; add the amine-based chai...

Embodiment 3

[0049] Different from Example 1,

[0050] The preparation method of externally repaired and internally solidified polyurea-based double-wall self-repairing microcapsules comprises the following steps:

[0051] (1) Preparation of prepolymer emulsion: mix the allophanate of the aliphatic isocyanate repair agent 1,6-hexamethylene diisocyanate and the amino-terminated polyether 1,4 butanediamine according to the mass of 1:3 Mix evenly to obtain a prepolymer; stir evenly at a rotating speed of 3000rpm, add an emulsifier and a solvent, and heat at 70°C for 2-3h at a rotating speed of 3000rpm to obtain a prepolymer emulsion; the amount of the emulsifier is 6% of the polymer mass, the mass ratio of the emulsifier to the solvent is 1:158.

[0052] (2) Preparation of amine-based chain extender emulsion: take an appropriate amount of emulsifier and solvent, stir at a speed of 1600rmp until mixed evenly; the mass ratio of the emulsifier to solvent is 1:48; add amine-based chain extender ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com