Folding-up mechanism for an electric treadmill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

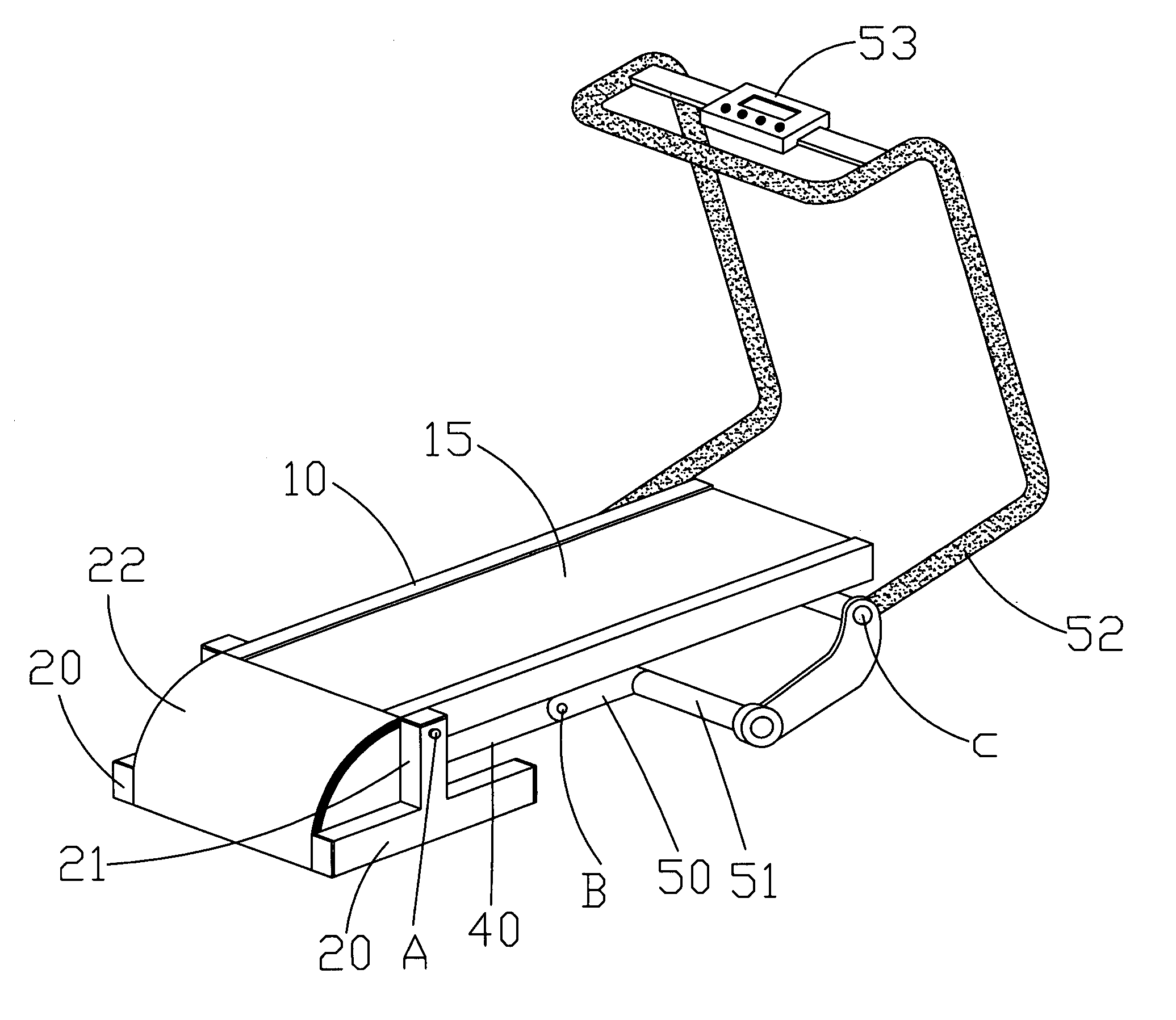

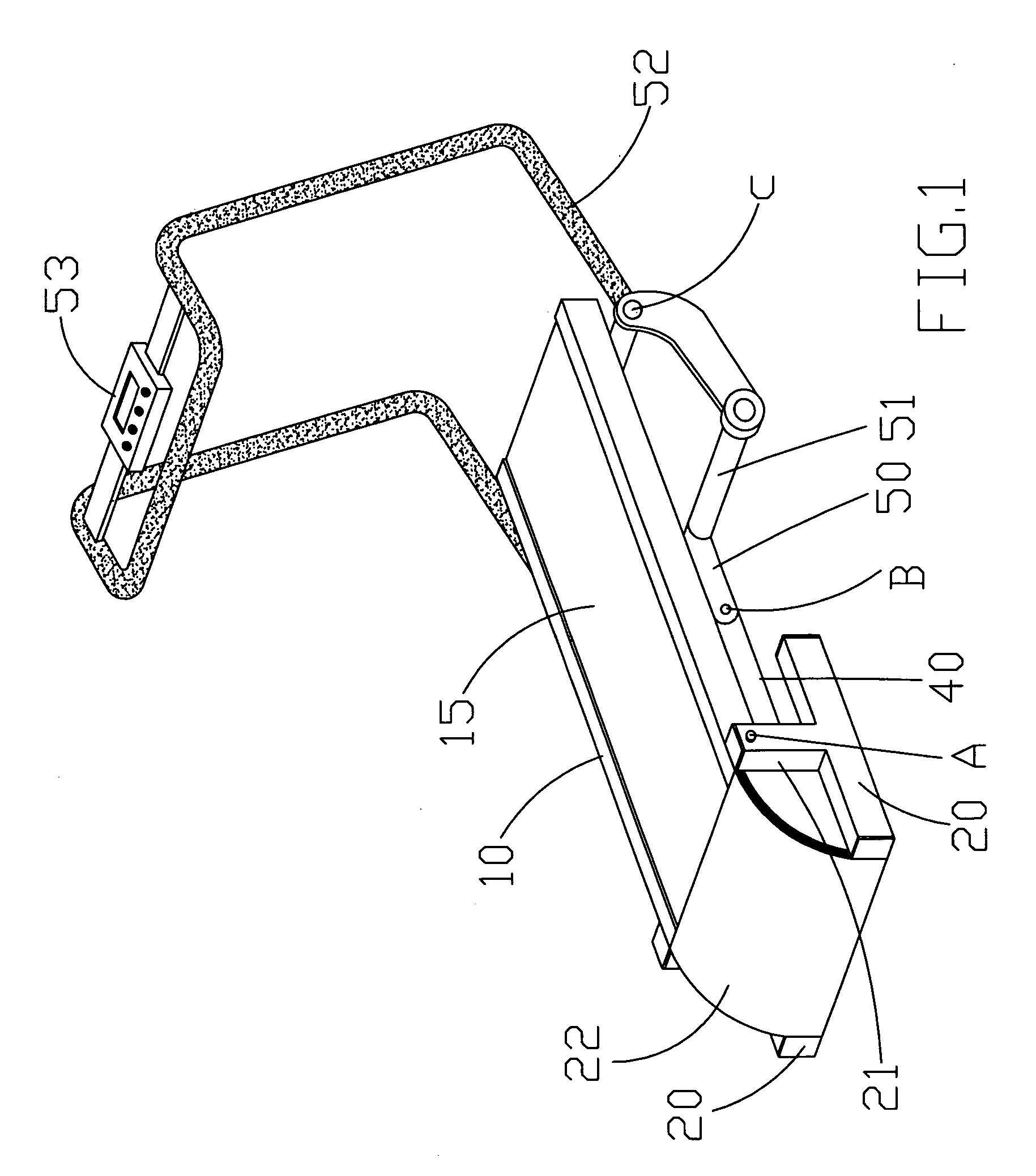

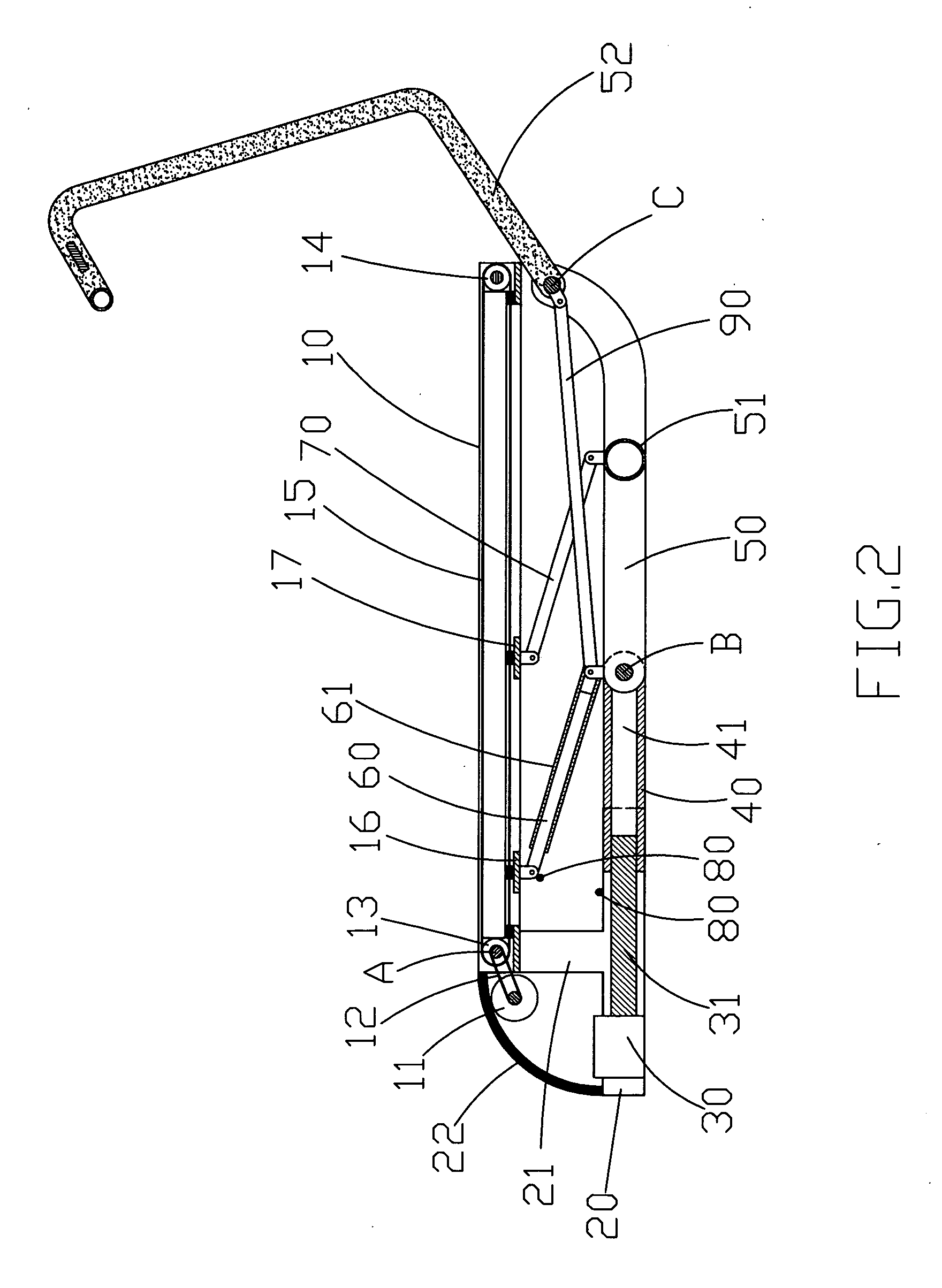

[0016] Referring to FIGS. 1 and 2, a treadmill in accordance with the invention includes:

[0017] a platform frame 10 having a rear roller 13 driven by a motor 11 through a driving belt 12, the rear roller 13 being active in cooperation with a front roller 14 for an in-place rotation of a continuous belt 15;

[0018] two base frames 20 having an upright bar 21 extending from a central point thereof, the platform frame 10 being pivotally connected to the upright bars 21;

[0019] a lifting motor 30 for driving a drive screw 31 to undergo an in-place rotation;

[0020] a slip pipe 40 having a female threaded hole 41 for receiving the drive screw 31;

[0021] an intermediate tube 50 pivotally disposed at a distal end of the slip pipe 40, a front crossbar 51 being connected at an opposing end of the intermediate tube 50, a handrail frame 52 extending upwardly from a rear end of the intermediate tube 50, an electronic console 53 being fitted atop the handrail frame 52;

[0022] a telescopic tube 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com