Shearing ring mold granulator

A shear ring and granulator technology, which is applied in the extrusion granulation of the die and the extrusion granulation of the raw material, can solve the problem that the extrusion radial force cannot be eliminated, and can prevent heat loss, improve accuracy and convenience. The effect of disassembly and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

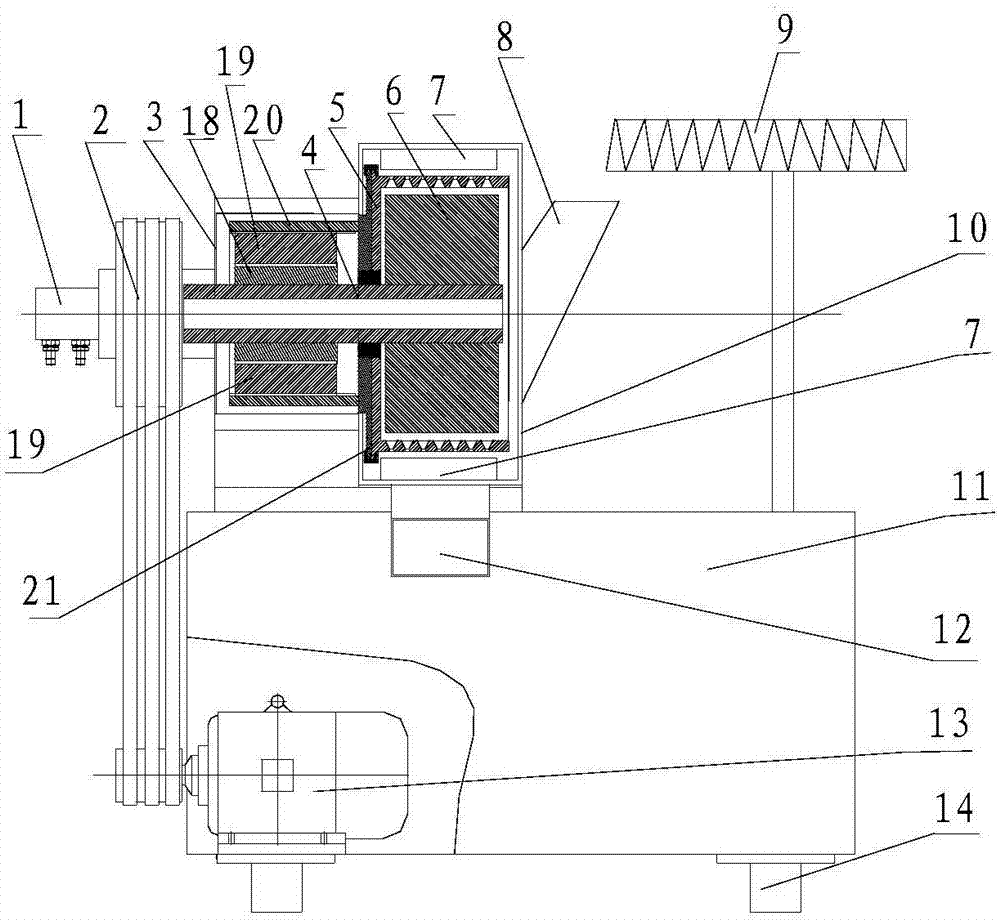

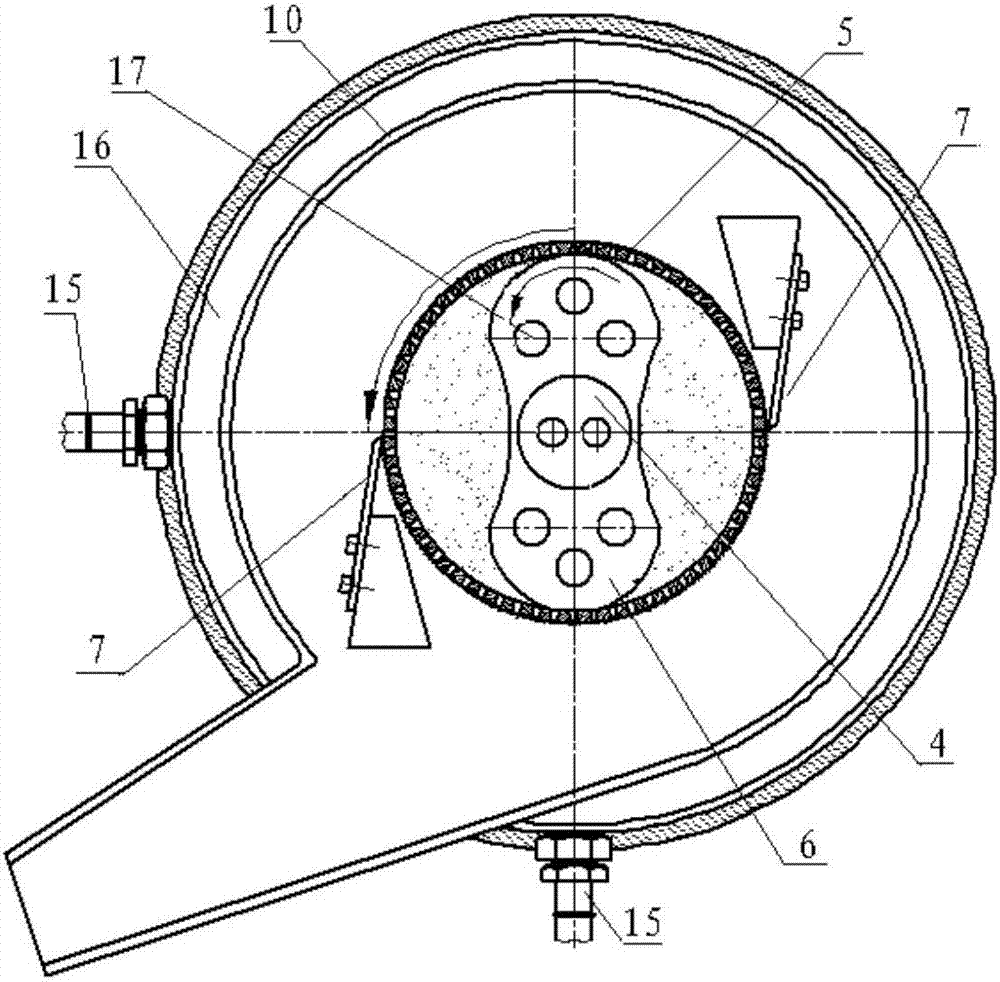

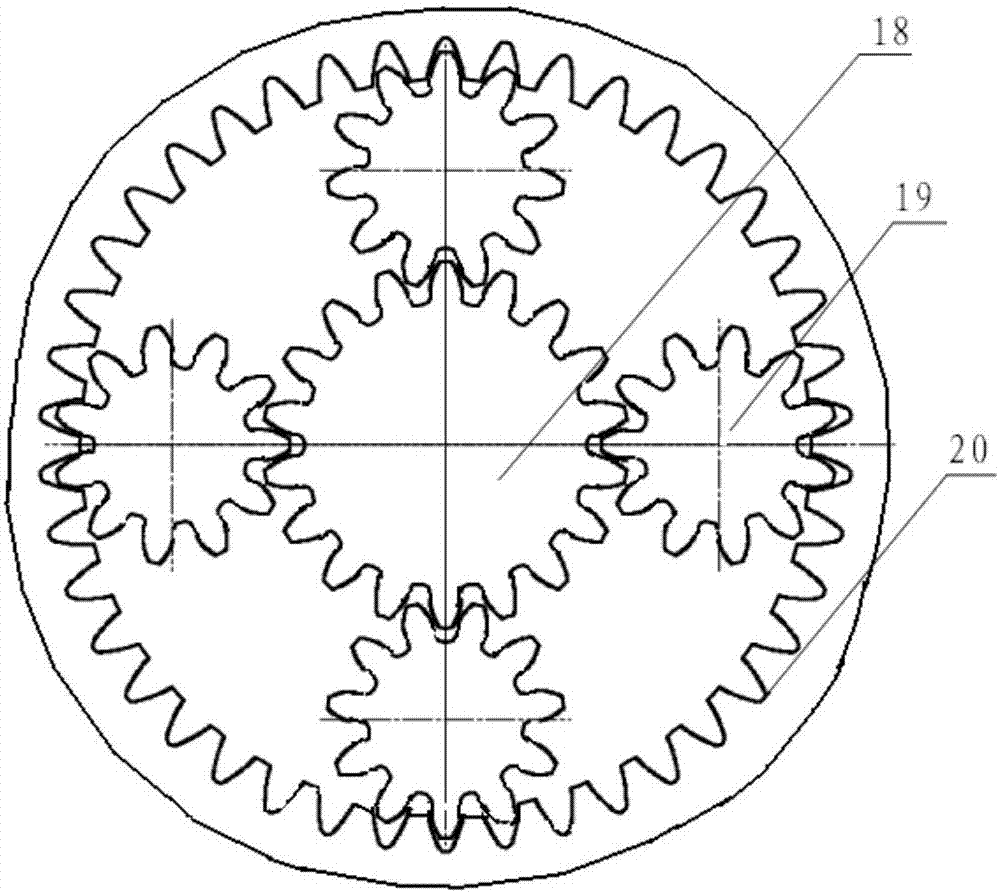

[0028] like figure 1 , figure 2 and image 3 As shown, a shearing ring die granulator of the present invention includes a motor 13, a pulley 2, a gear box 3, a main shaft 4, a ring die 5, a pressure roller 6, a cutter 7, a feed port 8, and a discharge port 12. Screw feeder 9, protective cover 10, circulating water pipe 1, base 11, base pillar 14, etc. The motor 13 , the gear box 3 and the screw feeder 9 are installed on the base 11 . One end of the main shaft 4 is connected to the belt pulley 2, and the other end is connected to the pressure roller 6. The transmission chain of the gear box 3 is composed of the main shaft gear 18, the planetary gear 19, and the ring gear 20. The main shaft gear 18 is installed on the main shaft 4, and the main shaft gear 18 meshes with the planetary gear 19, the planetary gear 19 meshes with the ring gear 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com