Turret positioning device of numerical control turret

A technology of positioning device and numerical control turret, which is applied in the direction of stripping device, metal processing equipment, forming tools, etc., can solve the problems of increasing the machining accuracy of parts, high coaxiality, and wear of parts, so as to reduce damage to parts and improve assembly efficiency , Increase the effect of lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

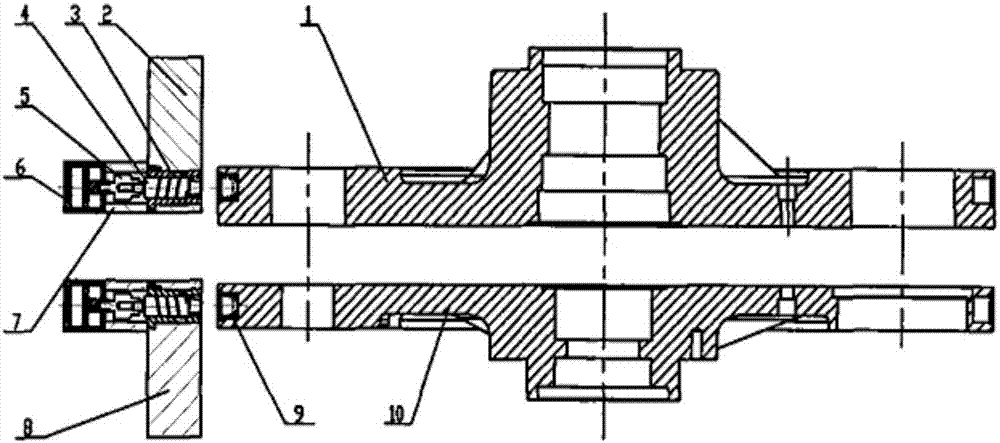

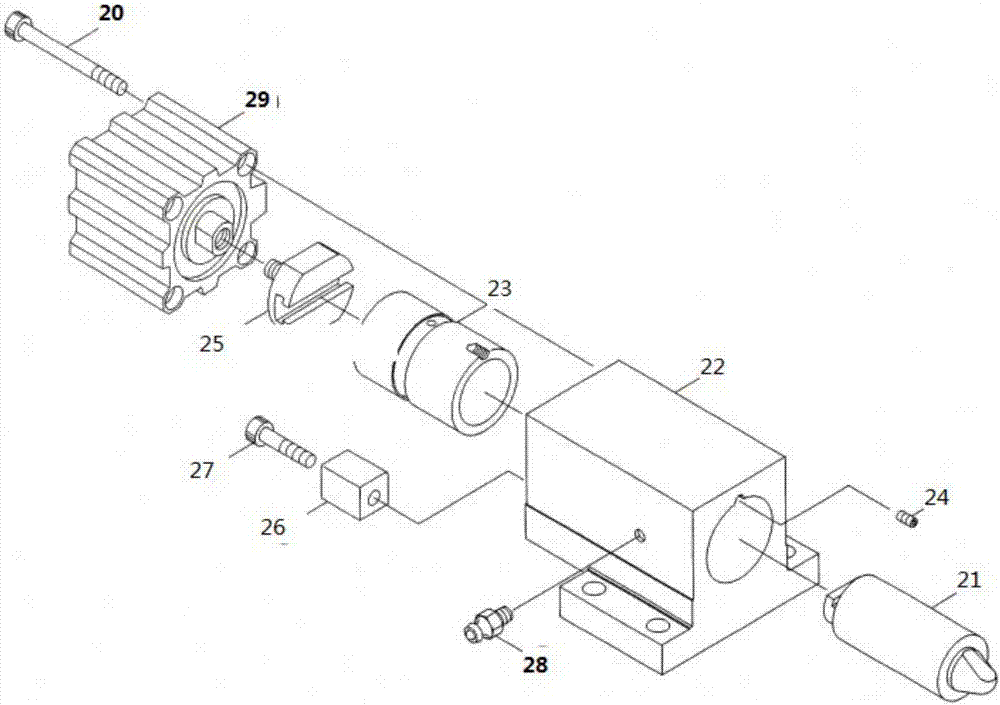

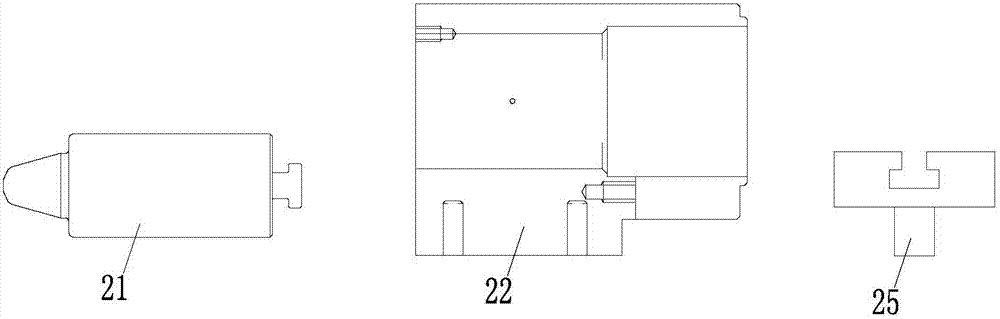

[0020] The turret positioning device of this embodiment includes a mounting block, a cylinder and a positioning pin. The mounting block has a cavity connected at both ends, the positioning pin is arranged in the cavity, and the cylinder is mounted in the cavity of the mounting block. One end of the body, the cylinder is connected with the positioning pin and can drive the positioning pin to move in the direction of cavity extension. A connector is installed between the cylinder and the positioning pin, one end of the connector is fixed to the cylinder through threads, the other end is provided with a T-shaped notch, and the end of the positioning pin is matched with a T-shaped connector. At the same time, a guide key is added to be parallel to the plane on the connector to play a guiding role and completely eliminate the generation of radial force. In addition, the installation block of the new turret positioning device is equipped with an oil nozzle, and there are correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com