Main shaft transmission used for gear measurement center

A technology for spindle drive and gear measurement, applied in the field of measurement, can solve the problems of complex debugging, maintenance, high cost, difficult manufacturing and processing, and achieve the effects of easy maintenance, solving the problem of slippage, and eliminating radial force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with accompanying drawing:

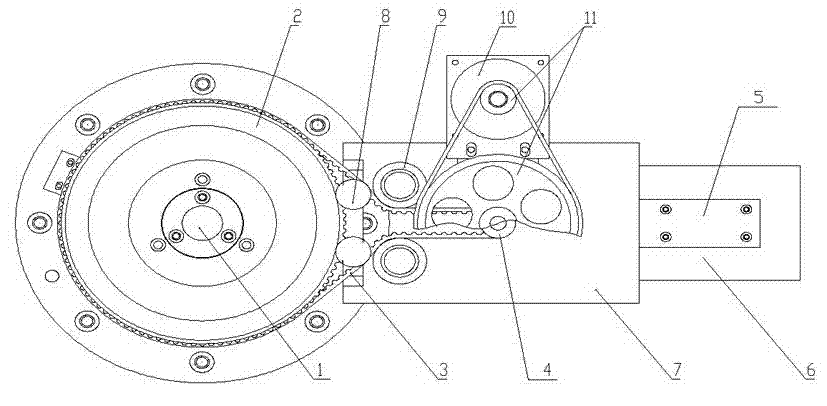

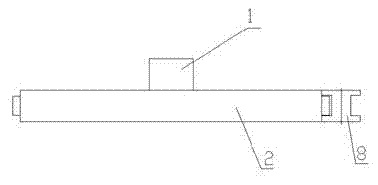

[0024] A spindle transmission device for a gear measurement center, comprising a measurement center spindle 1, a faceplate 2, a transmission belt 3, a transmission wheel 4 and a driving device, the transmission wheel 4 is connected to the drive device, the faceplate 2 is arranged on the measurement center spindle 1, and the faceplate 2 and the transmission wheel 4 transmit power through the transmission belt 3, and also include a base 6, a slide plate 7 and a pressing wheel 8, the base 6 is set on the radial side of the measurement center spindle 1, and the slide plate 7 is set on the base 6, the slide plate 7 and the base 6 are connected by the linear guide rail 5 arranged on the base 6, the linear guide rail 5 is arranged along the direction perpendicular to the measurement center spindle 1, and the driving device and the pressing wheel 8 are both arranged on the On the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com