Cold collapse method and apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

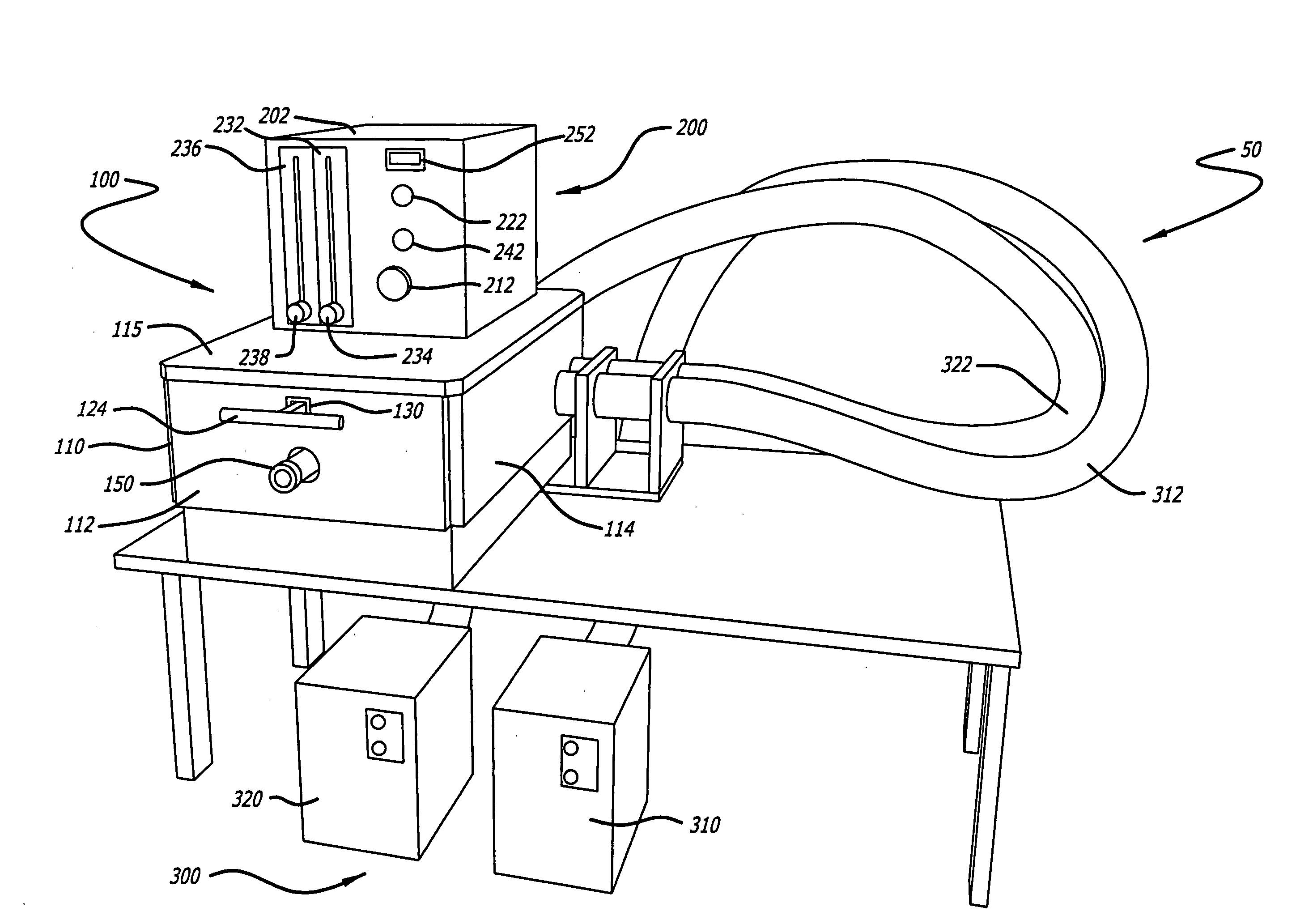

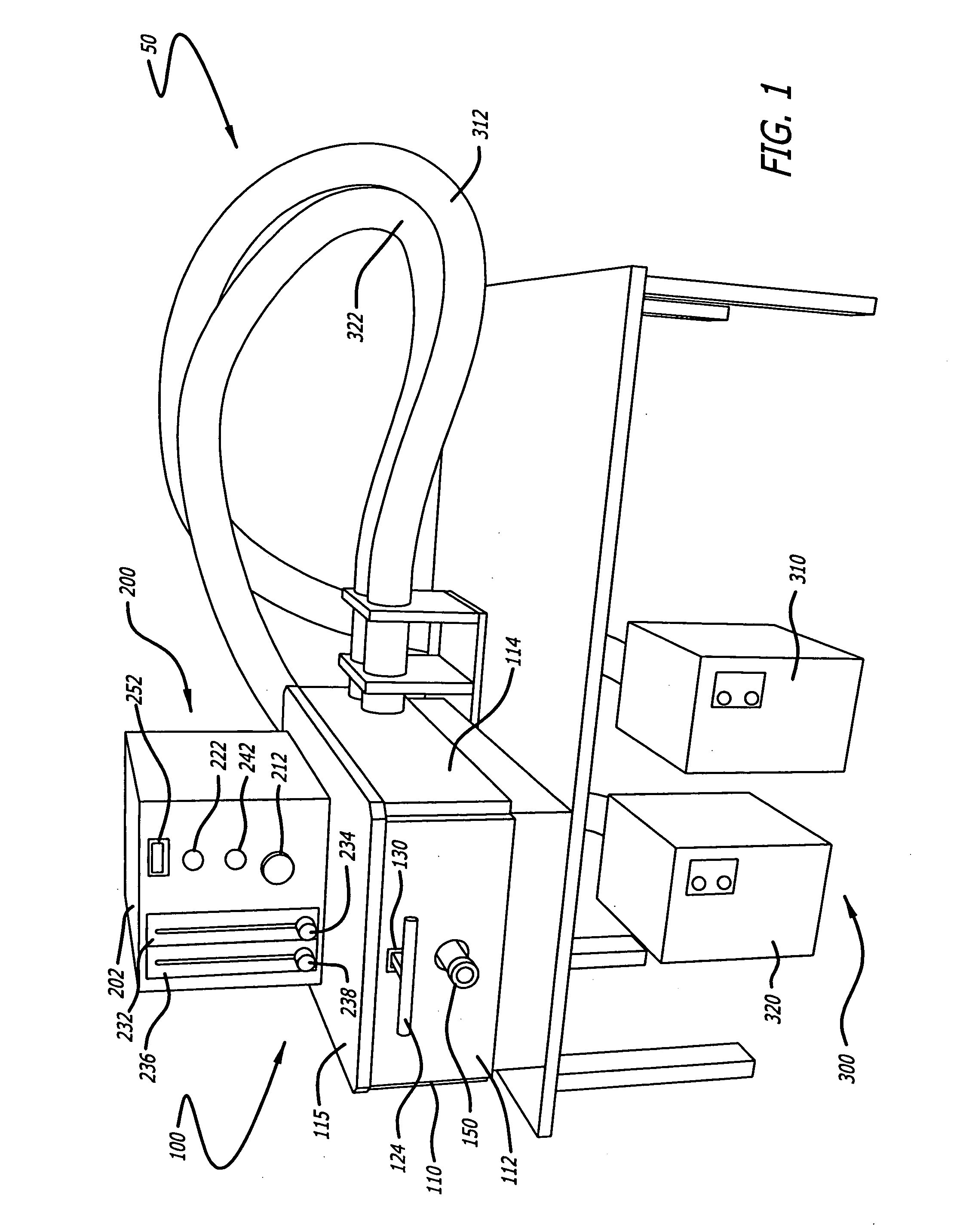

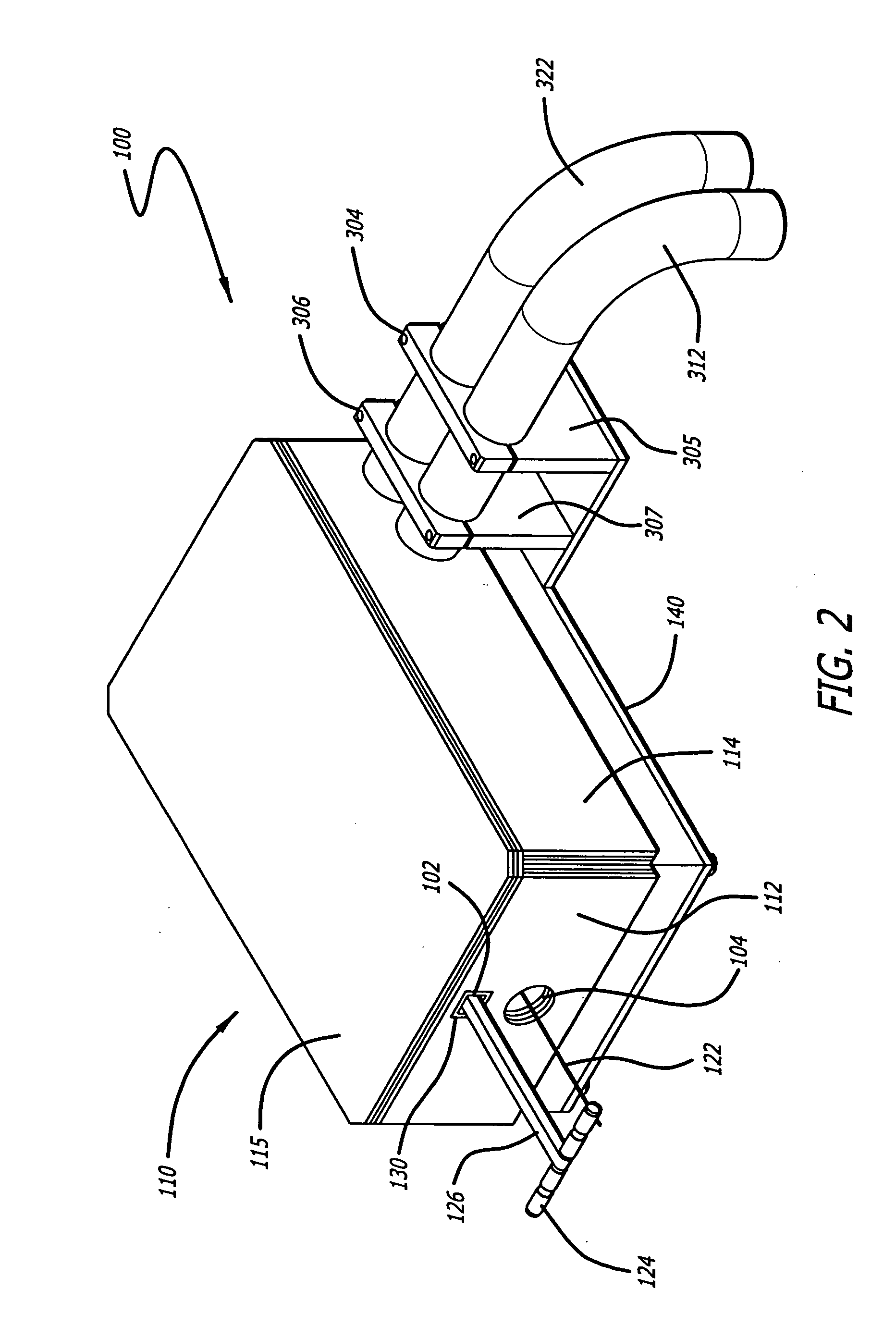

[0045]As shown in the drawings for purposes of illustration, the present invention is directed to a new system and method for collapsing and / or crimping a stent or medical device to a small diameter for the purpose of loading into a delivery catheter or onto a balloon catheter. The present invention is particularly useful with stents, grafts, tubular prostheses, embolic devices, embolic filters, and embolic retrieval devices. The collapser system and method of the present invention may also be used to crimp or collapse self-expanding and mechanically expandable stents or other medical devices, with or without a drug coating. The text herein and accompanying drawings are generally directed to self-expanding nitinol stents; however, those of ordinary skill in the art will appreciate that the various apparatus and methods described herein may be adapted for use with other devices and materials.

[0046]As shown in FIG. 1, the cold collapser system 50 of the present invention includes a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com