Adjustable floating reamer integrated with universal adjustment for roughing and finishing

A floating reamer and rough machining technology, applied in the direction of reamer, metal processing equipment, manufacturing tools, etc., can solve the problems of radial force, tool arc swing, etc., to improve production efficiency, eliminate errors, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

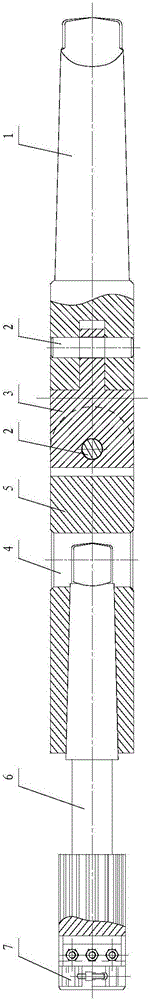

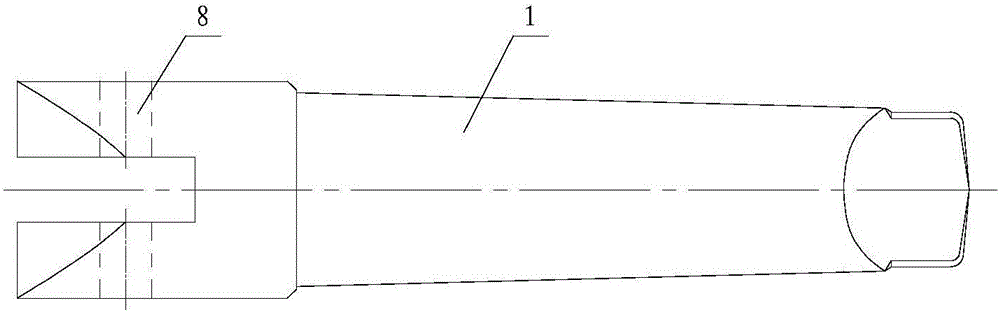

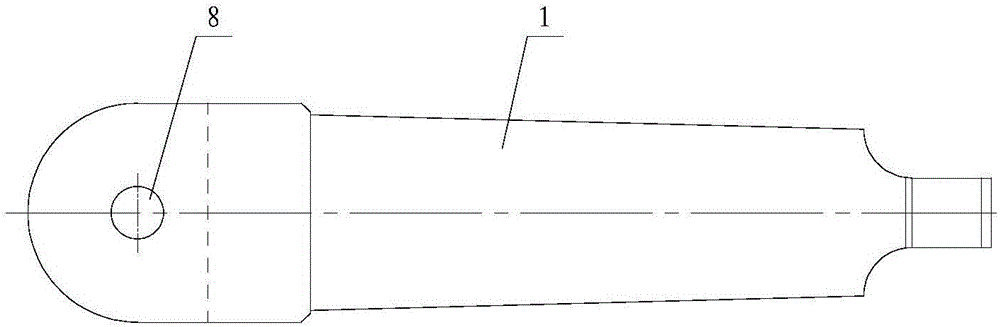

[0040] Such as figure 1 , Figure 4A and Figure 4B As shown, the present invention includes a universal adjustment tool bar, a roughing reamer 6 and a floating reamer 7, wherein the universal adjustment tool bar includes a tool bar handle 1, a universal joint 3 and a tool bar cover 5, and the tool bar handle 1 and Cutter sleeves 5 are respectively pinned to the two ends of the universal joint 3; one end of the tool bar of the rough machining reamer 6 is plugged on the cutter sleeve 5, and one end of the cutting edge is opened with a limit groove 10; the floating reamer 7 is accommodated in the limit In the positioning groove 10, and can float in the limiting groove 10, the rough machining reamer 6 limits the floating reamer 7 while processing the hole through the cutting edge.

[0041] Such as figure 1 , Figure 2A and Figure 2B As shown, one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com