A multi-area precise positioning method for large-format pcb boards

A PCB board, precise positioning technology, applied in the field of multi-area precise positioning of large-format PCB boards, can solve the problems of poor accuracy, inaccuracy, and low generality of PCB positioning technology, so as to eliminate deformation errors, improve computing efficiency, and improve generalization. The effect of sex and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

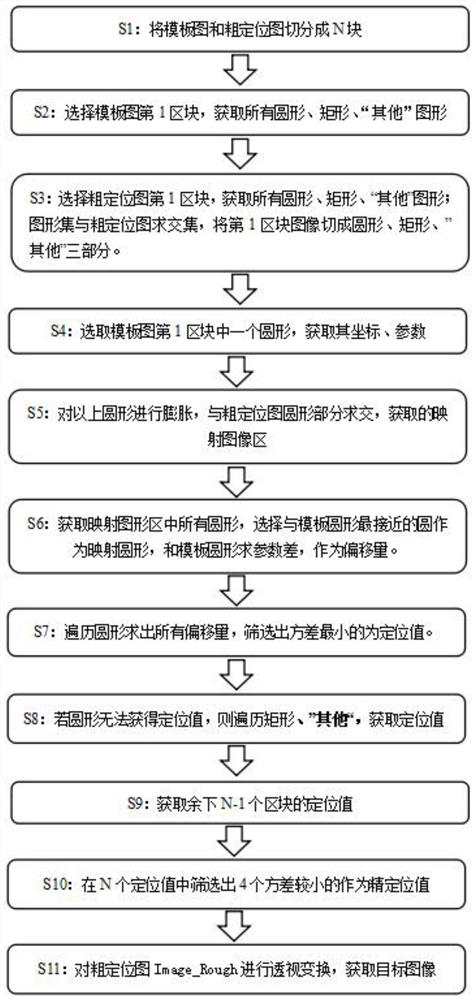

[0022] Embodiment: A multi-region precise positioning method for a large-format PCB board.

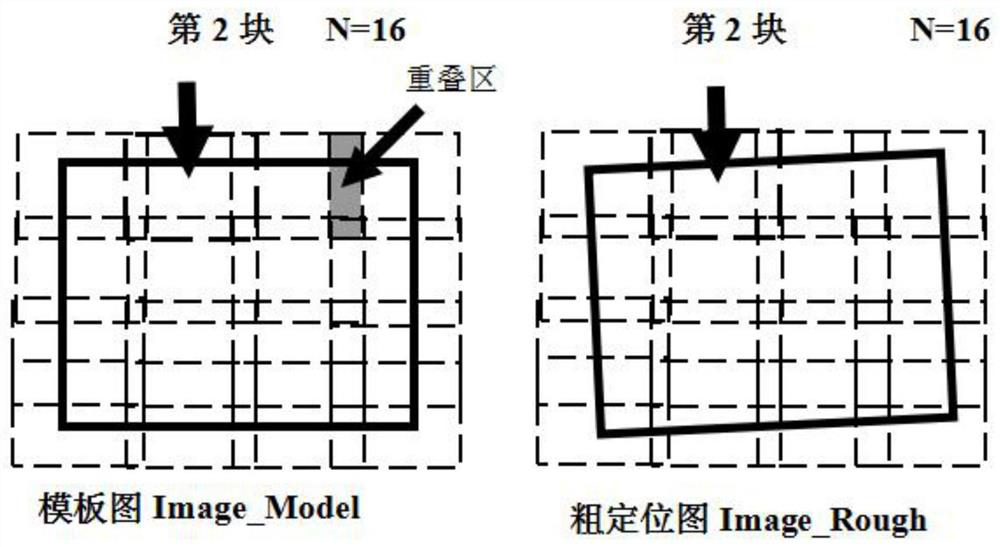

[0023] S1, divide the template image Image_Model and the rough positioning image Image_Rough into N blocks according to the preset segmentation area and overlapping area; The number N and the size of the overlapping area are preset according to the size of the original image, and the purpose of setting the overlapping area is to improve the accuracy.

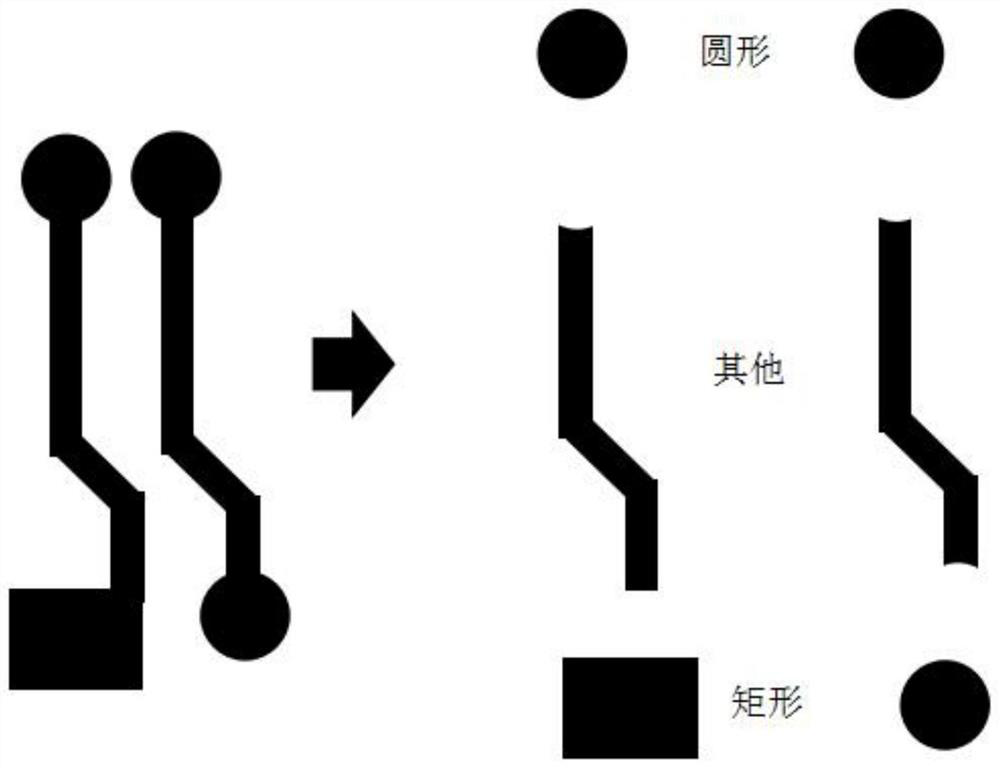

[0024] S2, select the first image block Image_ReducedM1 of the template map, perform a connected domain operation, and obtain all the graphics in it; use the circularity and rectangularity as the threshold, cut all the graphics in Image_ReducedM1 into three types: circle, rectangle and special shape kind.

[0025] S3, same as above, classify the graphics in the first graphic block Image_ReducedR1 of the coarse positioning map into three categories: circle, rectangle and irregular shape. The set of three types of graphics intersects wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com