New tension mandrel

A new type of mandrel technology, applied in the direction of expanding the mandrel, can solve the problems of increasing the difficulty of machining parts, small allowances, and troublesome manufacturing, so as to meet the needs of finishing, eliminate deformation errors, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

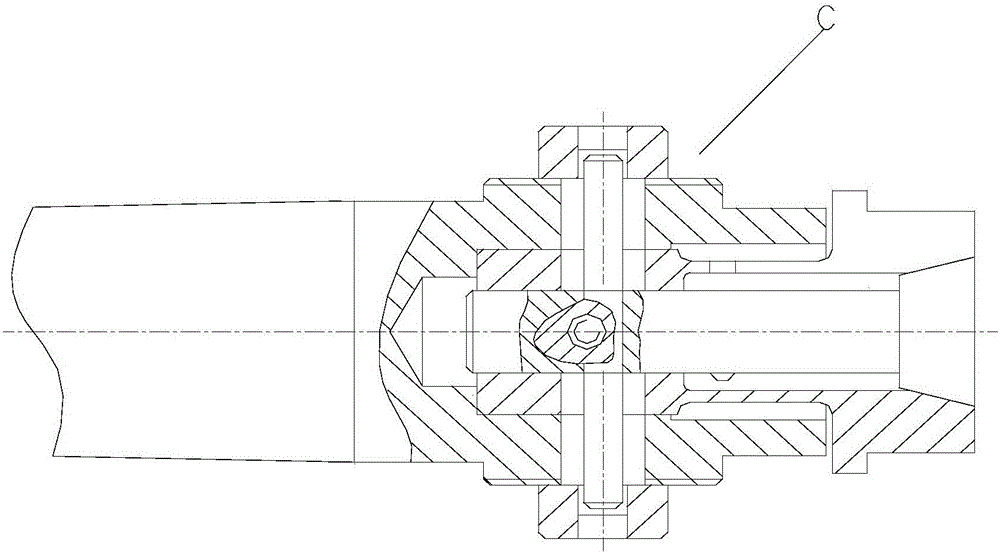

[0024] Attached below Figure 6-8 An embodiment of the present invention is described.

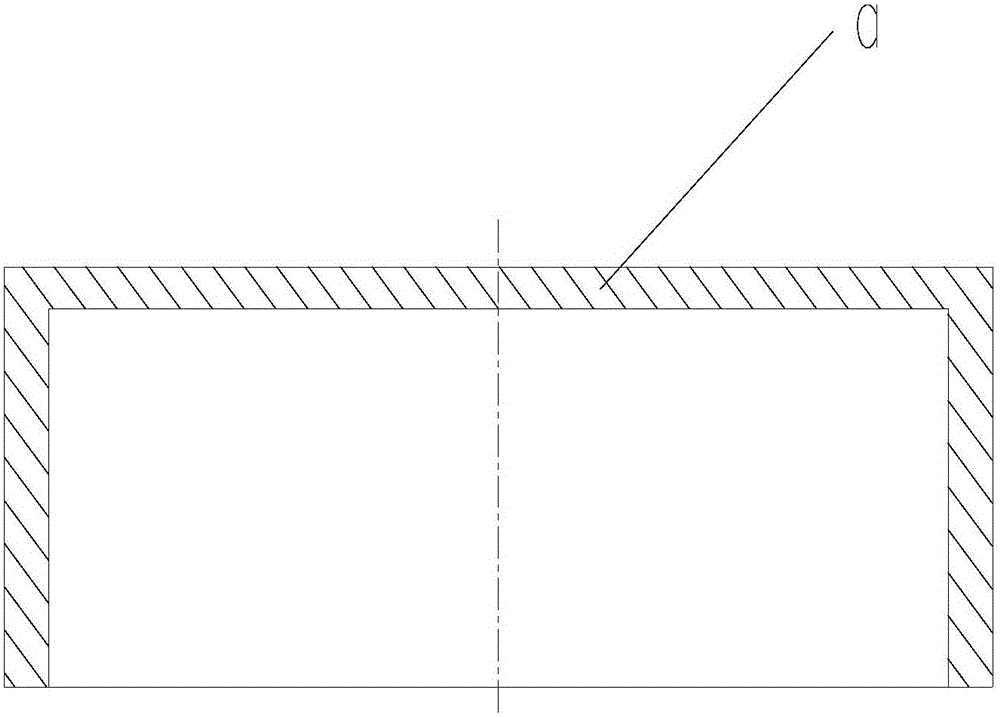

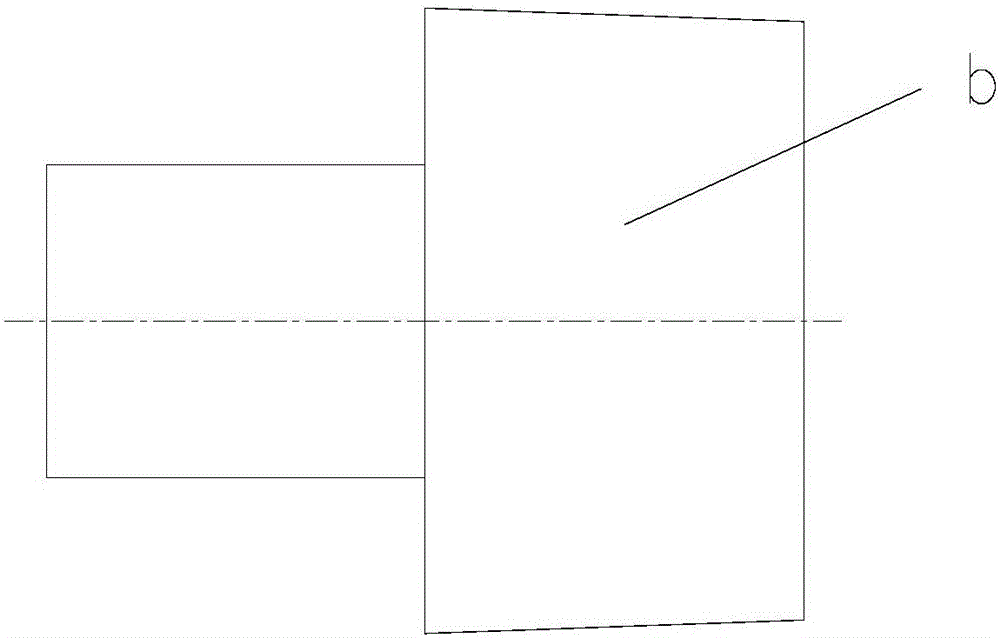

[0025] The new tension mandrel has an integrated mandrel clamp body 1. The integrated mandrel clamp body 1 lays the foundation for the coaxiality of the fixture, structural rigidity, and reduced manufacturing difficulty. The mandrel One end of the clamp body 1 is the clamping part 11 and the other end is the positioning part 12, and the tension part 13 is between the clamping part 11 and the positioning part 12; Groove 14, and the groove widths I and II of the tensioning groove 14 are symmetrical to the center line of the mandrel. Through this symmetry, the coaxiality of the fixture during the tensioning process can be ensured, the tensioning error can be reduced, and the machining accuracy can be guaranteed. Among them, The groove width I at the positioning part 12 is 0.5-5mm, and the groove width II at the tensioning part 13 is 1 / 5-1 / 3 of the diameter of the tensioning part 13. During ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com