Metal mine underground electric locomotive braking device

A technology for braking devices and electric locomotives, applied in the direction of pneumatic brakes, hydrostatic brakes, hydrodynamic brakes, etc., can solve the problems of long braking distances of electric locomotives, achieve improved braking effects, reduce braking distances, eliminate Effect of Radial Force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

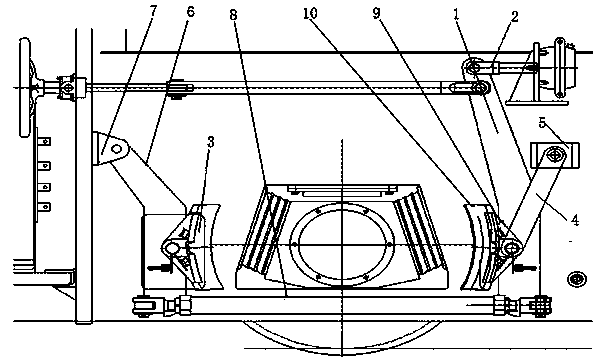

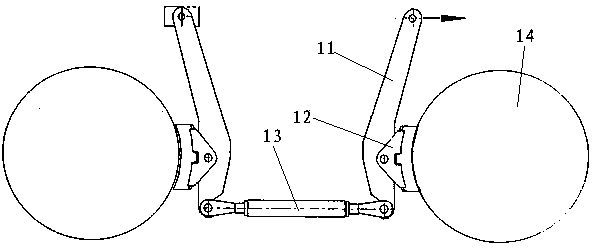

[0020] Such as figure 1 As shown, a braking device for an electric locomotive underground in a metal mine includes a lever 1, a cylinder 2, a brake shoe 3, a first group of special-shaped levers 4, a first group of hinge points 5, a second group of special-shaped levers 6, and a second group of hinged joints. Point 7, coupling 8, the upper end of the lever 1 is fixedly installed with the cylinder 2, and the lower part is installed with the brake shoe 3; one end of the first group of special-shaped lever 4 is connected with the brake shoe 3, and the other end is fixedly installed on the first group Hinge point 5; one end of the second group of special-shaped levers 6 is fixedly installed on the second group of hinge points 7, and the other end is connected to the brake shoe 3; the bottom end of the lever 1 is connected to the bottom end of the second group of special-shaped levers 6 The brake shoe 3 includes a brake shoe block 9 and a brake shoe holder 10, and the brake shoe b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com