Winding-free end-part spiral-motion induction motor

A technology of induction motor and spiral motion, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of complex mechanical structure, high processing cost, large device volume, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

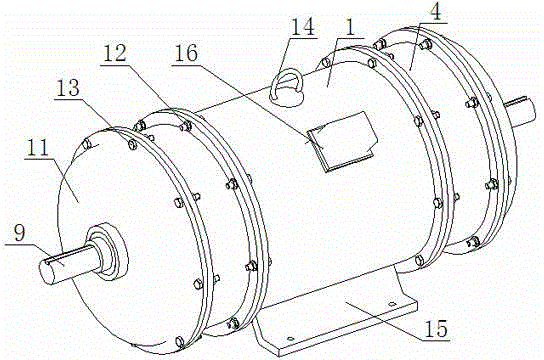

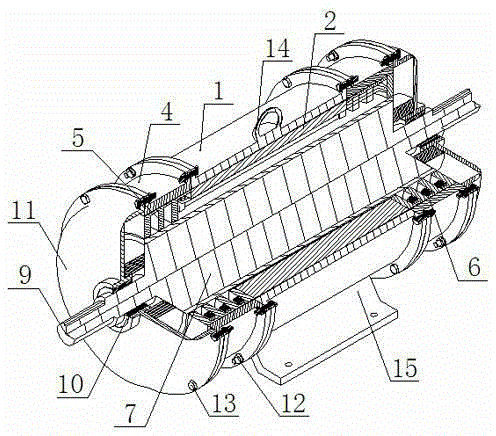

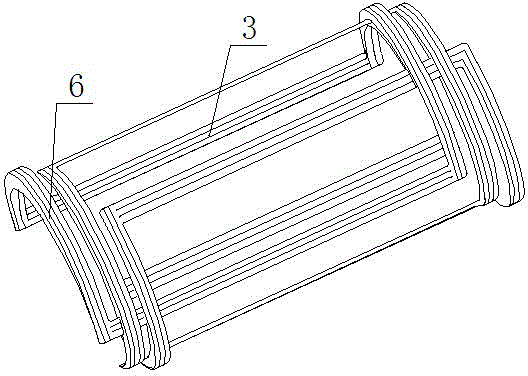

[0026] like Figures 1 to 14 As shown, the present invention includes a motor housing, a junction box 16 is arranged on the housing, a base 15 is arranged below the housing, and a stator core 2 at the straight part of the stator winding and a stator core 5 at the end of the stator winding are arranged in the housing. The stator core 2 of the straight part of the stator winding is formed by stacking silicon steel sheets with tooth grooves along the axial direction of the rotating shaft 9 , and the tooth grooves of the stator core 2 on the straight part of the stator winding form slots along the axial direction of the rotating shaft 9 . The stator core 5 at the end of the stator winding is provided at both ends of the stator core 2 in the straight part of the stator winding. The slots on the stator core 5 at the end of the stator winding form slots along the circumferential direction of the rotating shaft 9 and the axial direction of the rotating shaft 9 respectively. Slots are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com