Low-speed multipole synchronous generator

A synchronous generator and multi-pole technology, which is applied to synchronous machines, synchronous motors with stationary armatures and rotating magnets, electric components, etc., can solve the problems of unallowable use of generators and complicated manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

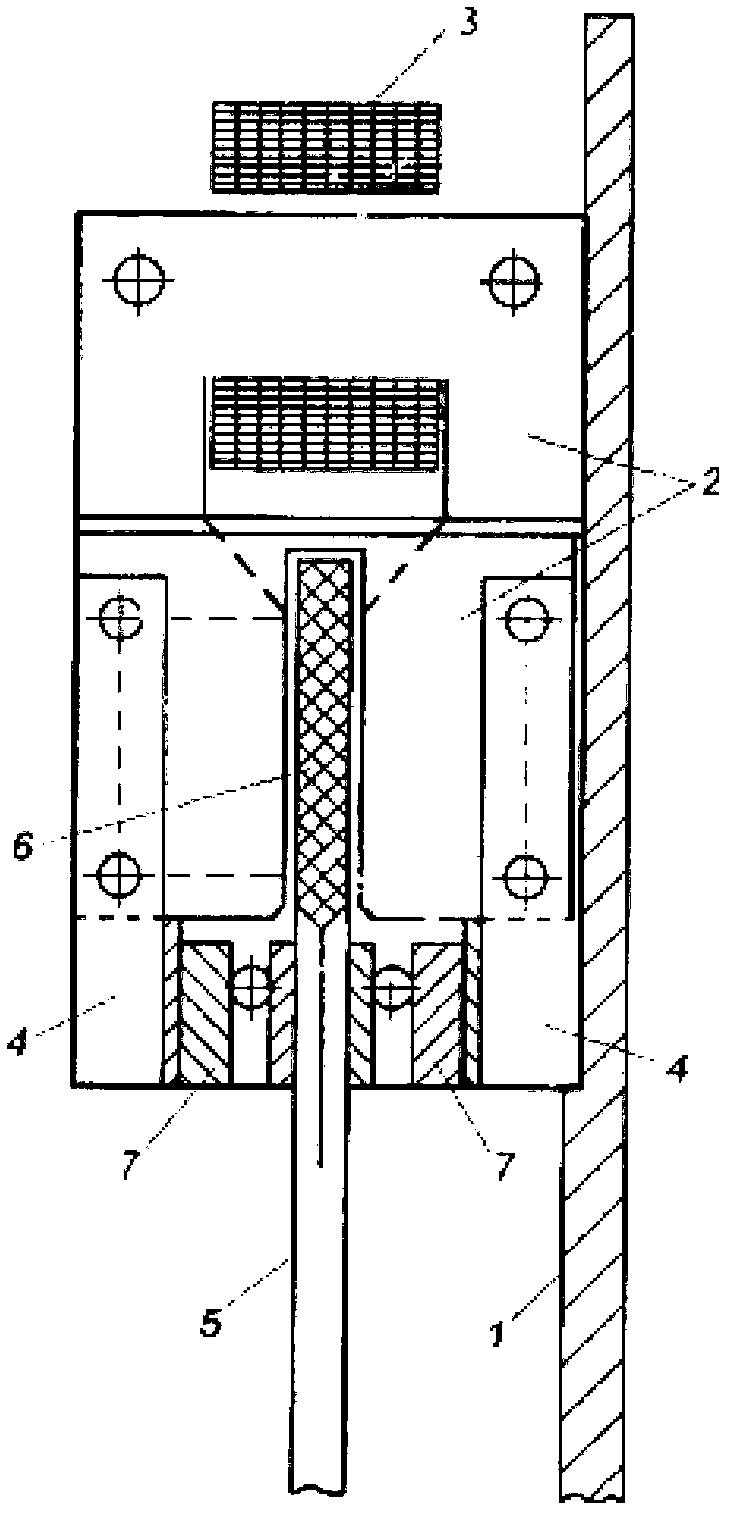

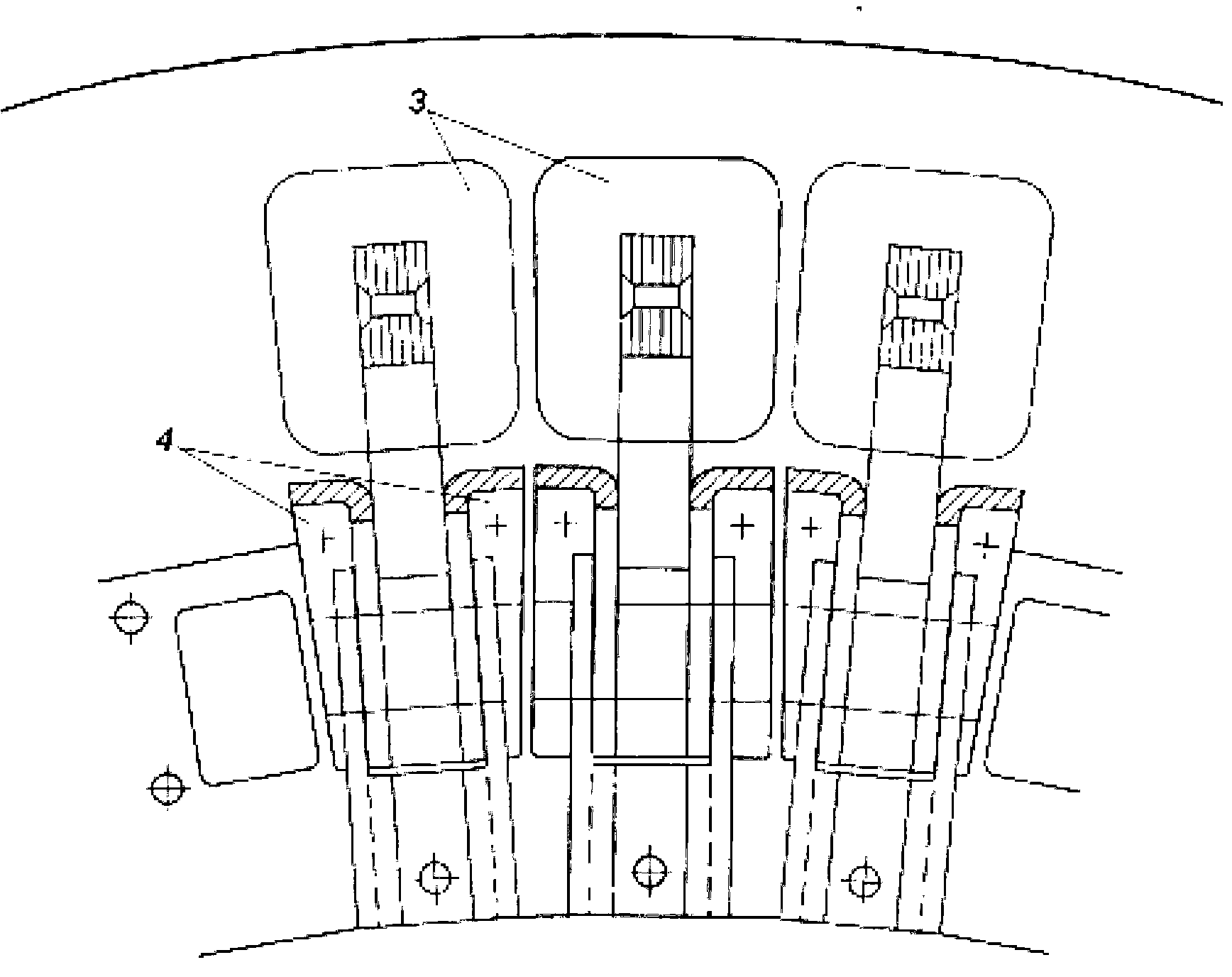

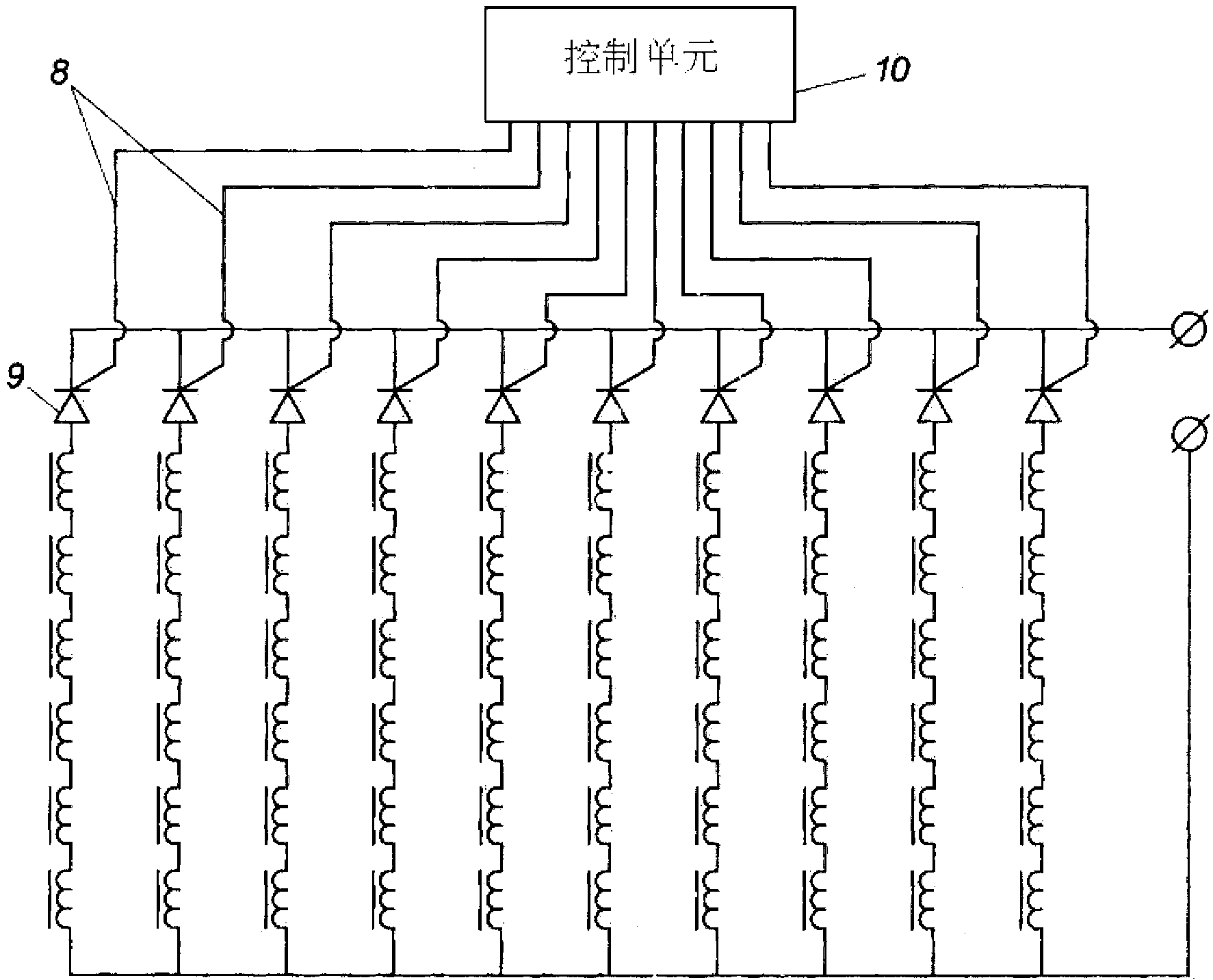

[0024] The low-speed multi-pole synchronous generator includes a housing 1 on which a stator 2 with a stator coil 3 is fixed, and the stator coil 3 is wound on an n-shaped magnetic conductor 4 .

[0025] On the shaft of the low-speed multipole synchronous generator (shaft not shown in the figure) is fixed a rotor 5 made in the form of a disc with inserts made of permanent magnets 6 . The permanent magnets 6 are installed in the rotor 5 alternately with respect to the direction of magnetization. At this time, the permanent magnets 6 are installed on the rotor 5 in such a way that the magnetizers 4 of the stator coils 3 are displaced circumferentially, that is, every 10th permanent magnet 6 or the magnetizers 4 of the stator coils 3 are arranged opposite to each other, so that Whichever is the most shall prevail. This ratio ensures a reduction in movement for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com