Large-span steel truss girder bridge whole joist full-welding joint welding method

A technology for steel truss bridges and welding methods, applied to welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of heavy bolt screwing workload and poor working environment, so as to reduce workload, reduce usage, Reduce the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

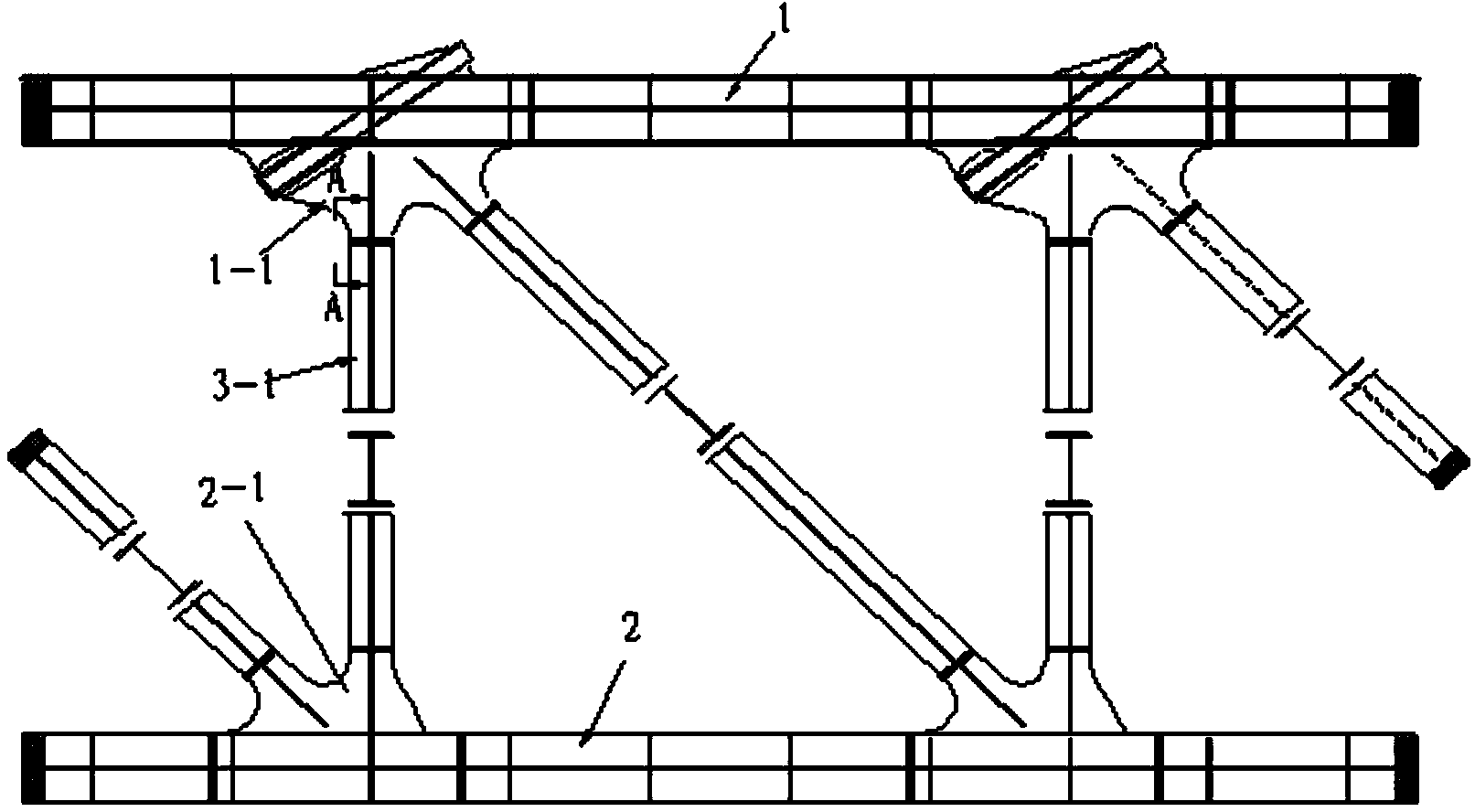

[0038] The specific embodiments of the present invention will be further explained below with reference to the accompanying drawings. The method for welding the integral truss of a large-span steel truss bridge includes the following steps:

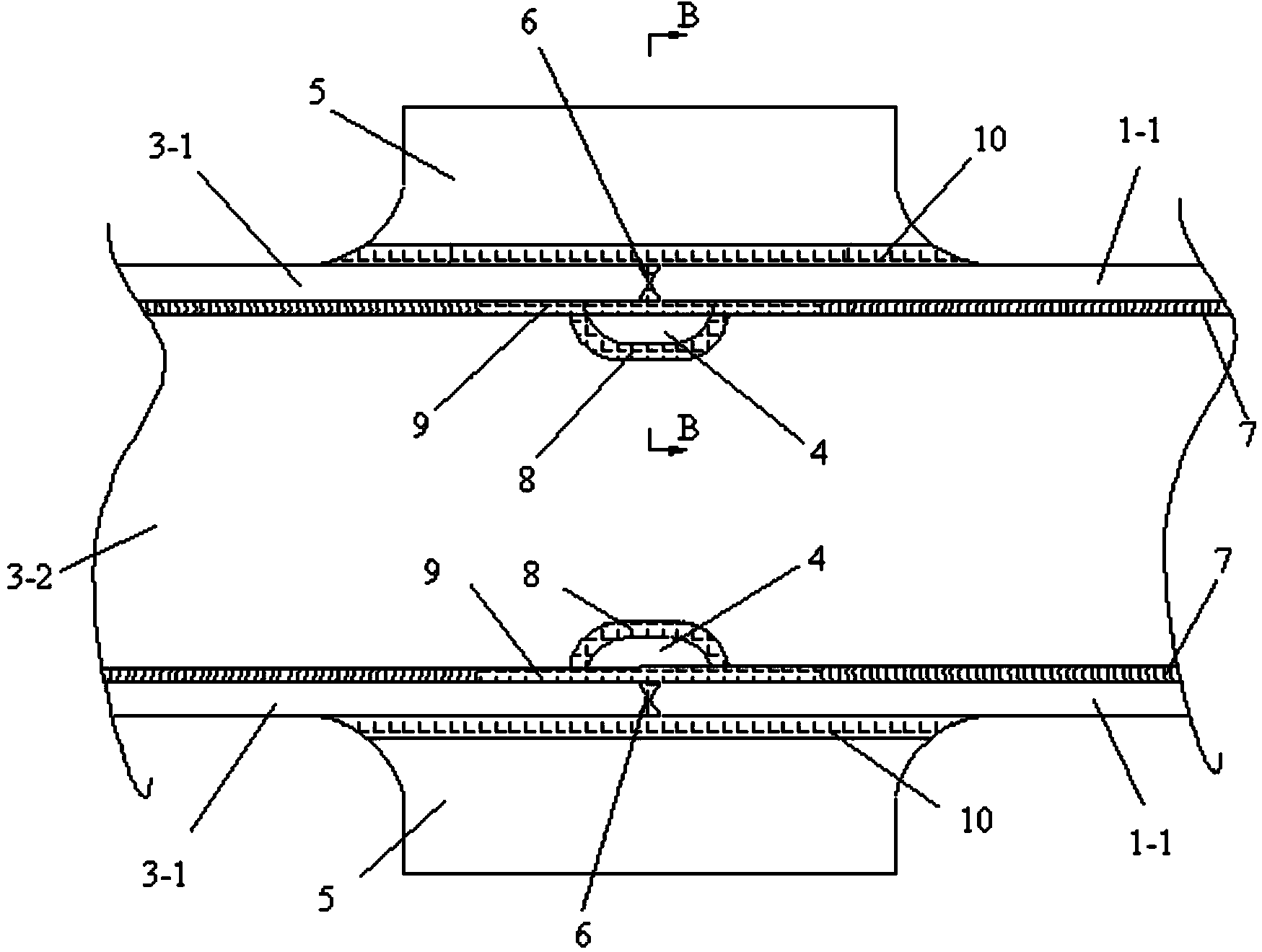

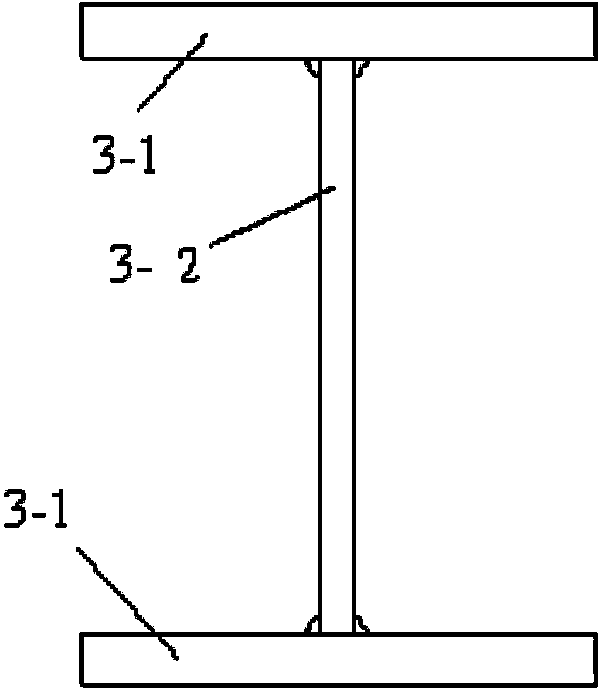

[0039] A. Prefabricated members: upper chord 1, lower chord 2, upper chord integral gusset 1-1, lower chord integral gusset 2-1, web cover 3-1 and web 3-2;

[0040] The above-mentioned prefabricated rods also include double-sided V-shaped grooves for the butt welds between the web cover 3-1 and the upper and lower chord integral gusset plates, 2mm blunt edges, 0-3mm gap, and groove angle of 60-70 ° to ensure the smallest possible amount of weld metal filling and welding distortion.

[0041] B. Assemble and weld prefabricated rods to form integral trusses;

[0042] The assembled and welded prefabricated members include: the upper chord 1 and the lower chord 2 are positioned on the tire frame, and the web members are assembled after the position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com