Design internal stress analyzing method for hinged hollow plank girder bridge with reinforced transverse prestress

A transverse prestressed, hollow slab girder technology used in bridge reinforcement, bridge construction, bridges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

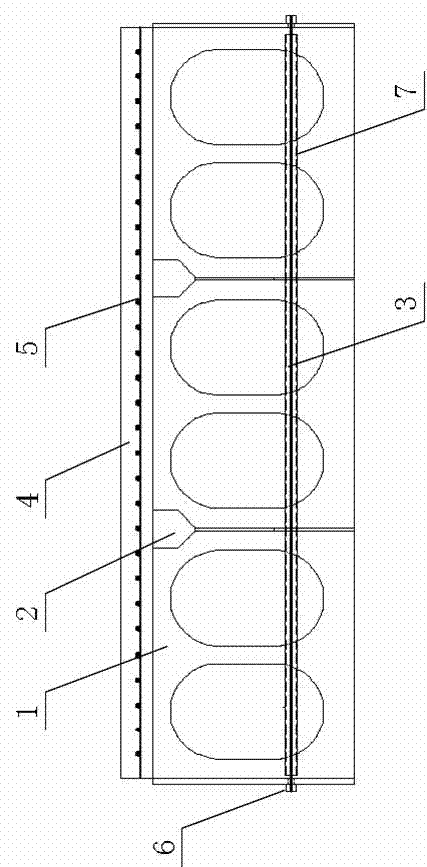

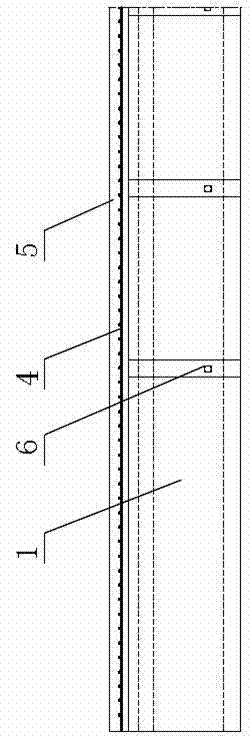

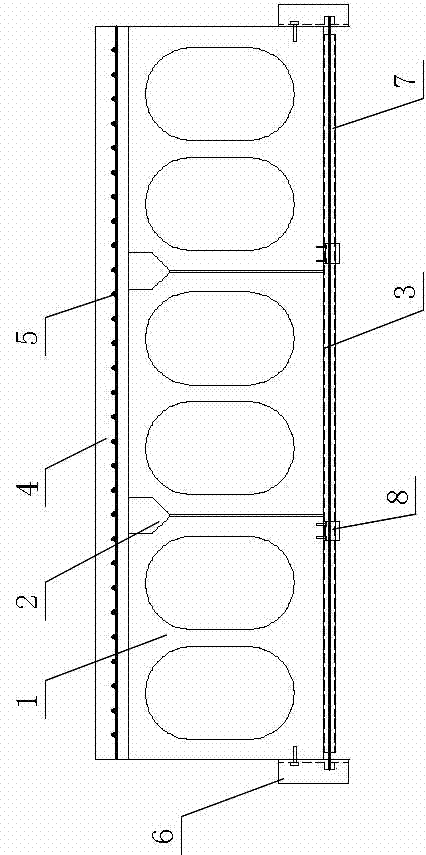

[0023] Please refer to the attached figure 1 to attach Figure 7 As shown, a horizontally prestressed hinged hollow slab girder bridge consists of a concrete hollow slab girder 1, hinge joints 2, transverse prestressed steel bars 3, bridge deck pavement concrete 4, bridge deck pavement steel bars 5, side girders The anchoring system 6, the anti-corrosion fatigue prestressed steel pipe 7 and the prestressed steel pipe fixing device 8 are composed of several parts.

[0024] However, due to the effect of the transverse prestressed steel bar 3, the structural form and stress characteristics of the reinforced bridge are changed. The transverse shear force and bending moment can be transmitted between the plate girders at the same time. The increase in transverse rigidity makes the load not only in the longitudinal direction, At the same time, it spreads in the horizontal direction, so it is necessary to analyze and calculate the design internal force of the reinforced bridge.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com