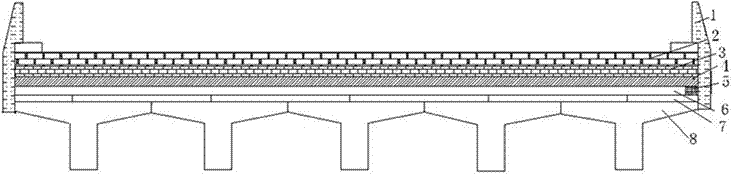

Construction method of T-shaped girder bridge pavement with graphene heating film

A technology of graphene heating film and construction method, which is applied in the construction field of T-shaped beam bridge pavement using graphene heating film, which can solve the problems affecting people's travel and personal life safety, increasing the speed of snow melting on the bridge area, bridge deck and bridge body structure Corrosion and other problems, to facilitate daily travel, shorten the icing period of the bridge deck, and prevent the snow on the bridge area from freezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

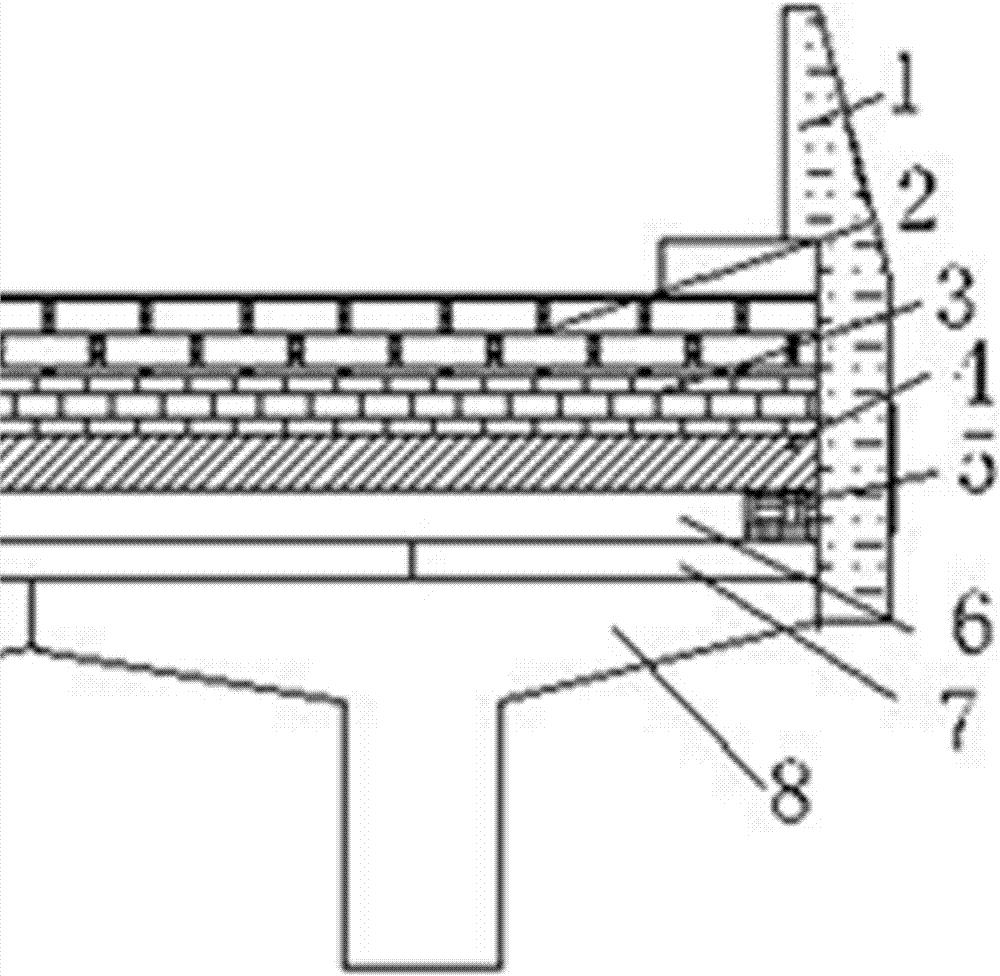

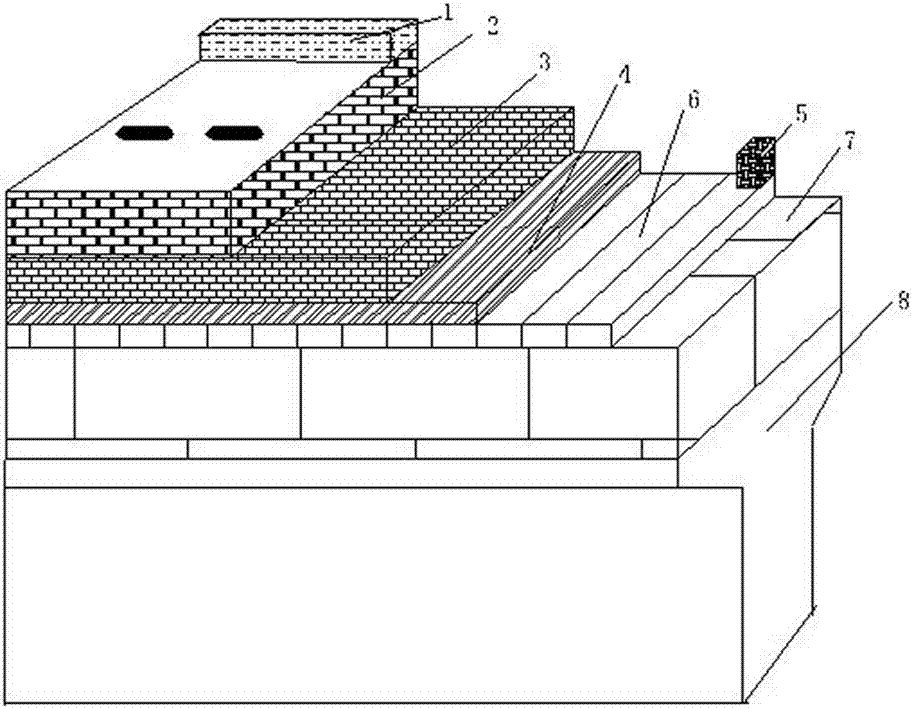

[0018] Embodiment 1: The thickness of the first-class road pavement surface layer is 15cm, the thickness of the base layer is 38cm, and the thickness of the subbase layer is 40cm. A 5mm graphene heating film is laid between the surface layer and the base layer.

[0019] When laying the 40cm subbase and the 38cm base, it is necessary to strictly follow the technical plan for paving. The cement-stabilized gravel soil is mixed with a certain amount of gravel (generally not more than 50%). The compaction degree of the subbase is 95.9, the water content is 4.1, and the compaction degree of the base is 94.9, and the water content is 4.3%. After the paving is completed, before laying the 5mm graphene heating film, the bridge deck should also be inspected, and problems such as pits and looseness on the bridge deck should be repaired in time.

[0020] When laying and laying 5mm graphene heating film, it is necessary to remove the debris on the base of the bridge deck, so that the diam...

Embodiment 2

[0022] Example 2: The thickness of the upper layer AC-13 fine-grained asphalt concrete for the first-class road pavement is 5cm, the thickness of the middle surface layer AC-20 medium-grained asphalt concrete is 7cm, the waterproof layer is 1cm, and the thickness of the base cement gravel is 19cm , the thickness of the cushion gravel is 38cm. A 5mm graphene heating film is laid between the waterproof layer and the middle surface layer.

[0023]When laying a 10cm reinforced concrete layer, it is necessary to strictly follow the technical plan for paving. When the steel bar is bent no more than 90°, the inner diameter of the bending arc at the bend should not be less than 5 times the diameter of the steel bar. The joints of steel bars should be set at places with less stress, and two or more joints should not be set for the same longitudinally stressed steel bar. The distance from the end of the joint to the bending point of the steel bar should not be less than 10 times the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com