Receding construction method of cradle of continuous girder bridge made of prestressing concrete

A construction method and prestressing technology, applied to bridges, bridge construction, erection/assembly of bridges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

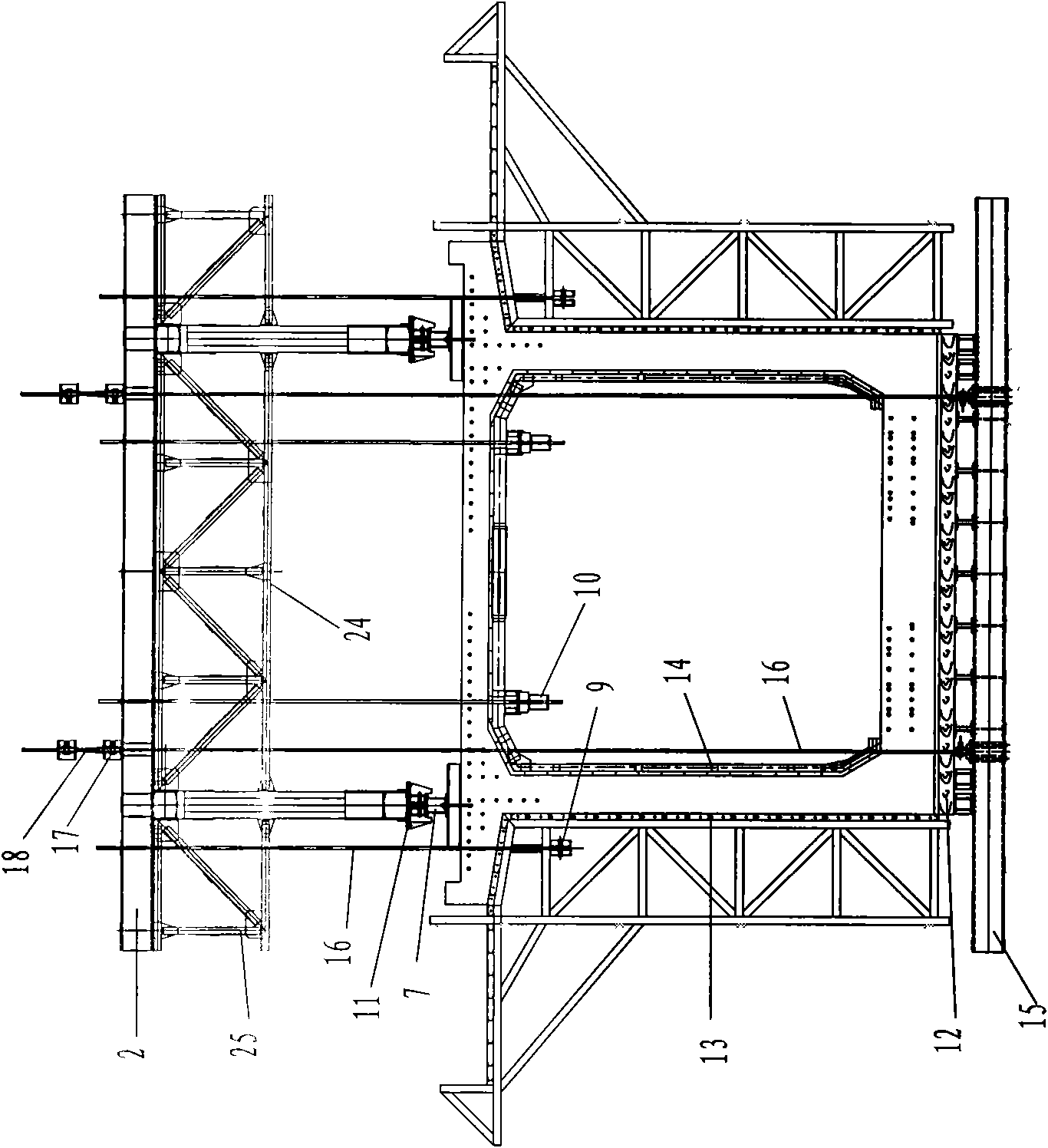

[0045] The gantry truss walking device of the present invention is formed by adding a sub-gantry to the outer side of the main truss girder. The main truss includes upper and lower beams, front and rear oblique pull beams, columns or channel steel columns connected, and the outer side is made by adding a sub-gantry Extended sub-gantry; The extended sub-gantry is made of channel steel and angle steel.

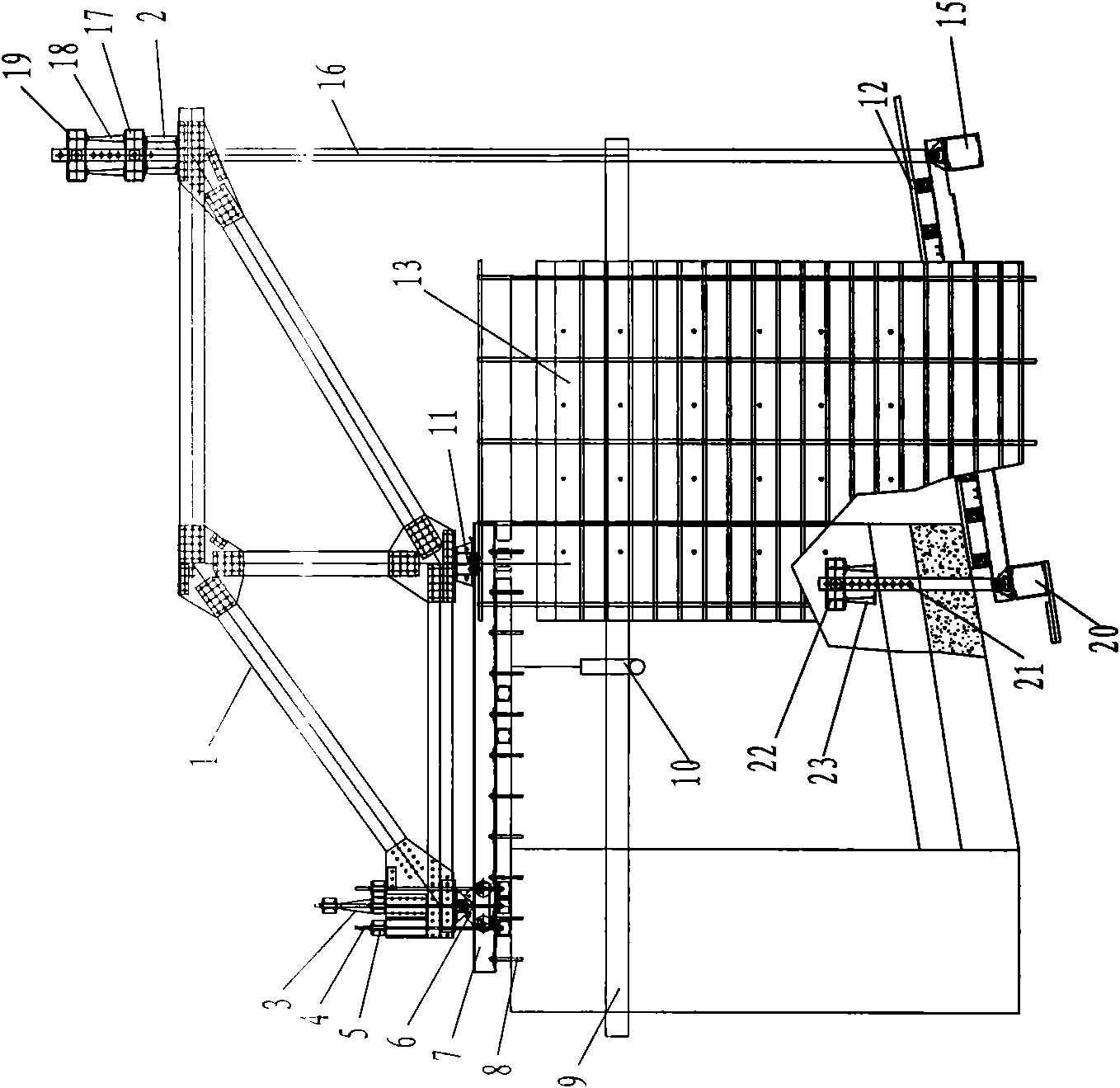

[0046] In the construction equipment of the present invention, it mainly includes an extended top beam (2), a front bottom beam (15) and a rear bottom beam (20). Die connection system (sling, beam pin seat, jack connection), hanging basket back and other steps.

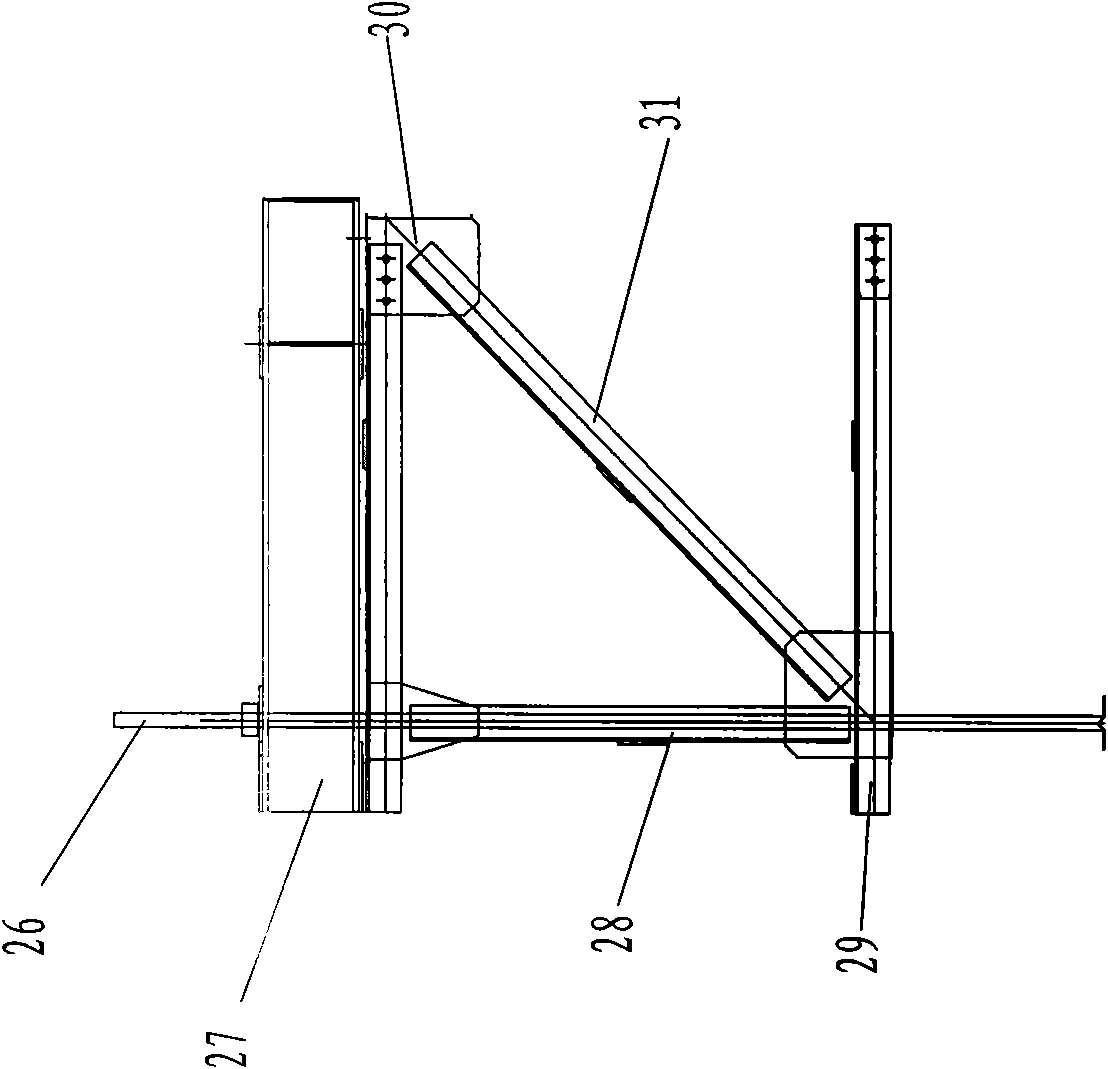

[0047] exist image 3 , Figure 4 , Figure 5 In the shown implementation, when making the extended sub-gantry (25), at first utilize two (12) channel steels to be welded side by side to form the combination of the extended sub-gantry pole beams (27), and the distance between the two channel steels is 40mm. --50mm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com