Coupling Removal Tool

A technology for removing tools and couplings, which is applied in the mechanical field, can solve problems such as damage, difficulty in control, and poor safety, and achieve the effects of avoiding injury accidents, prolonging service life, and convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

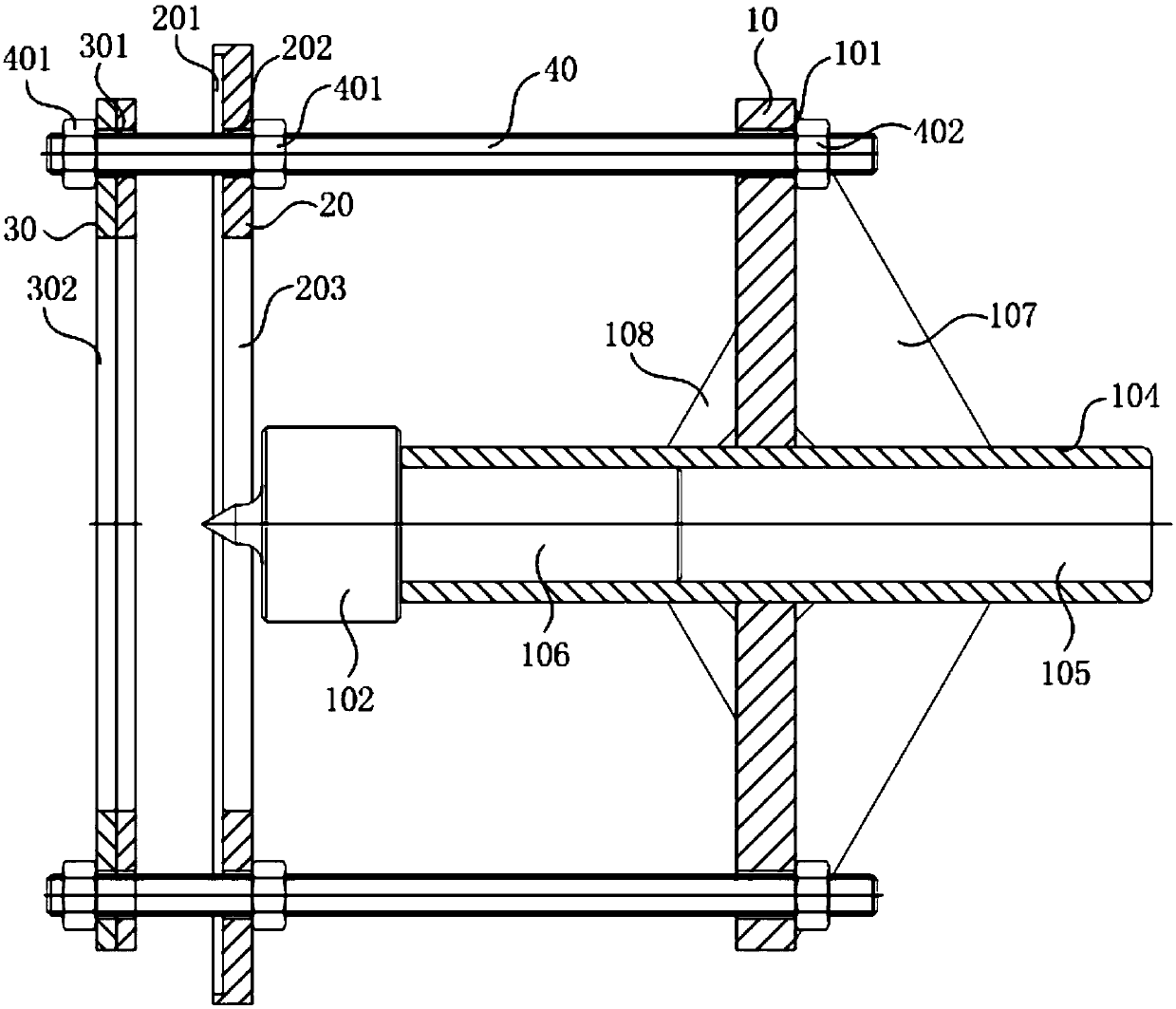

[0047] The specific implementation of the shaft coupling removal tool provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

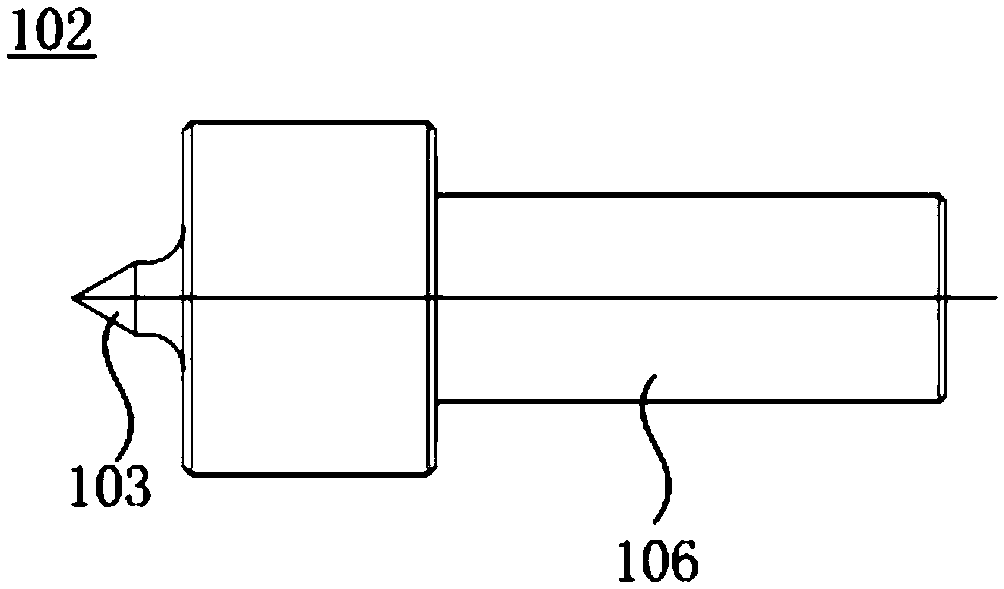

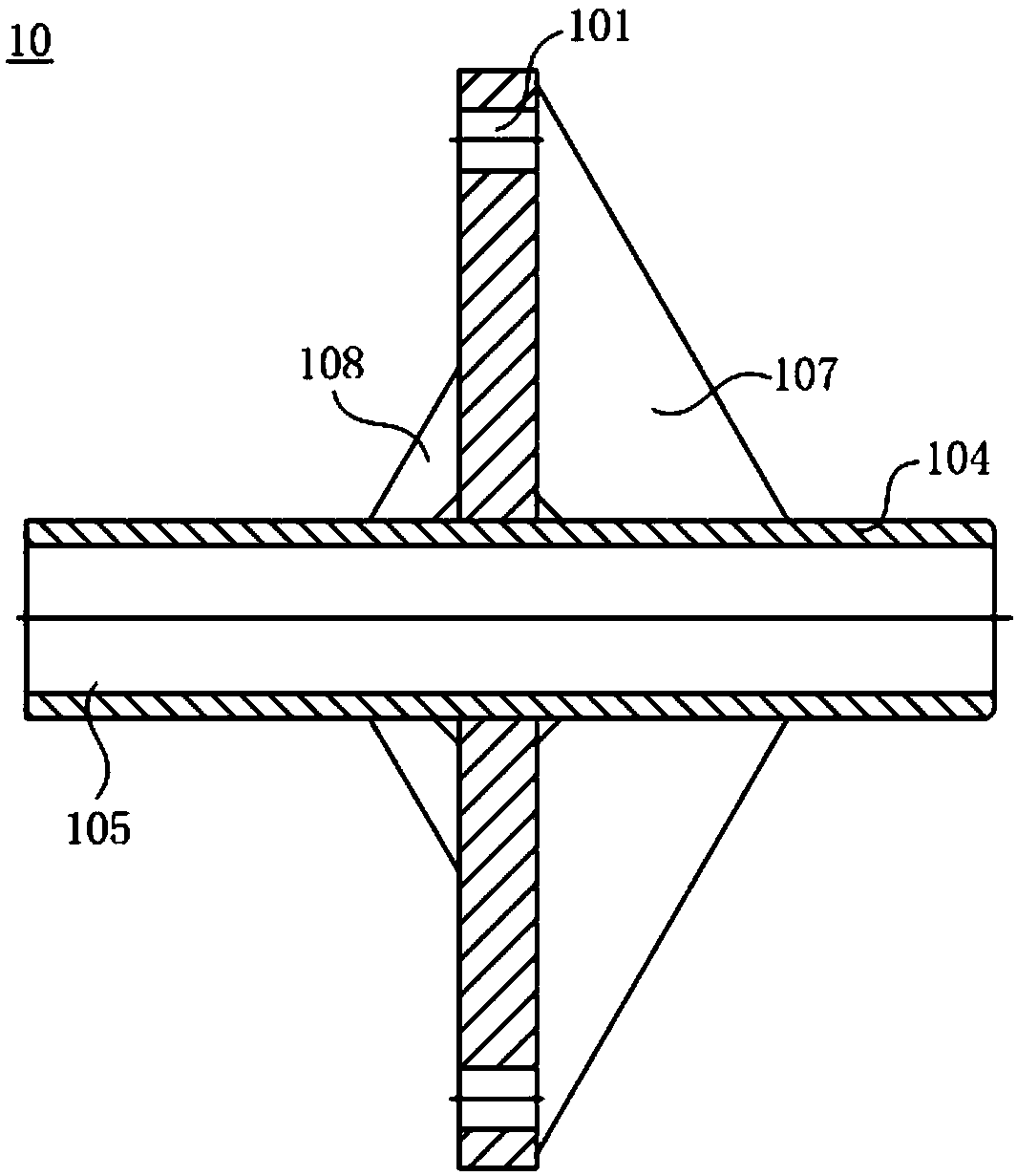

[0048] see figure 1 , The coupling removal tool of the present invention includes a base 10 , an outer fixed disk 20 and at least two sets of inner fixed disks 30 .

[0049] The base 10 has at least two first connection holes 101 . The first connection hole 101 and the shaft coupling 60 (marked on Figure 7 ) on the pin hole 601 (marked on Figure 7 ) coaxial setting. The pitch circle of the first connecting hole 101 is the same as that of the pin hole 101 , and the diameter of the first connecting hole 101 is the same as the small end of the pin hole 601 . Further, the number of the first connection holes 101 is the same as the number of the bolt holes 601 , or half of the number of the bolt holes 601 . Preferably, in order to further enhance the detachment effect of the coupling removal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com