Method for assembling and disassembling portal crane and auxiliary supporting structure

A gantry crane and auxiliary support technology, which is applied to the bottom support structure, traveling mechanism, hoisting device, etc., can solve the problems of increasing safety risks for operators, difficulty in assembling and dismantling, and large site limitations. Flexible form, safe and reliable assembly and disassembly process, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

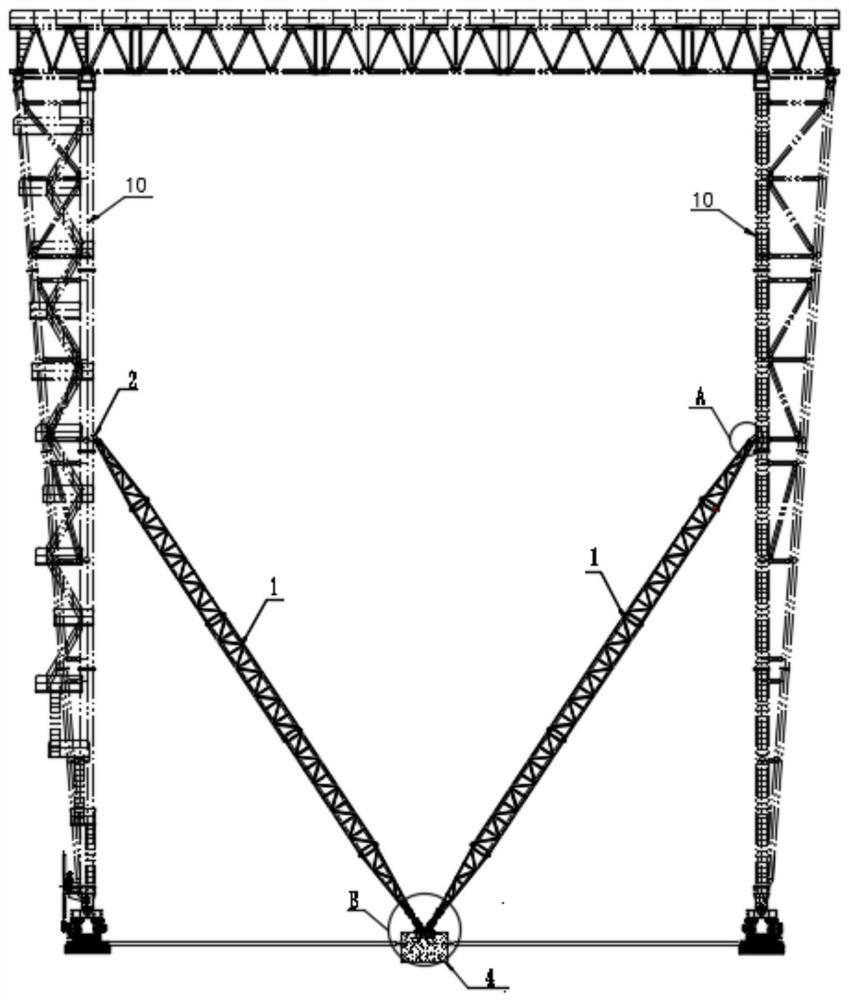

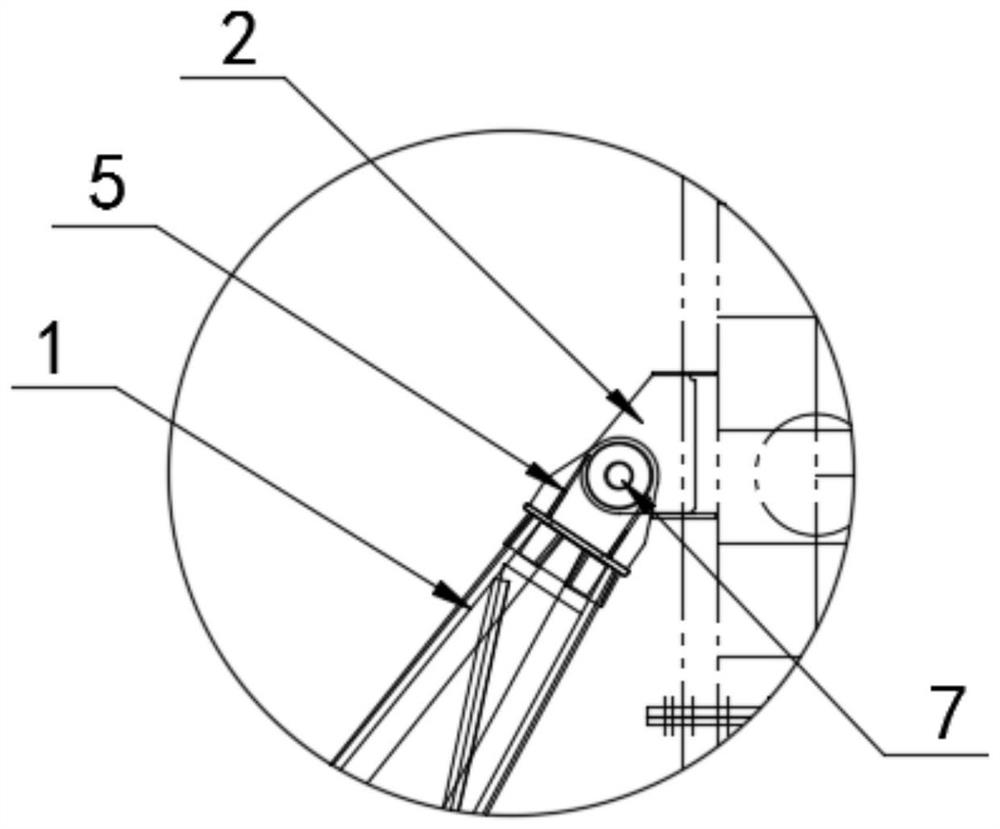

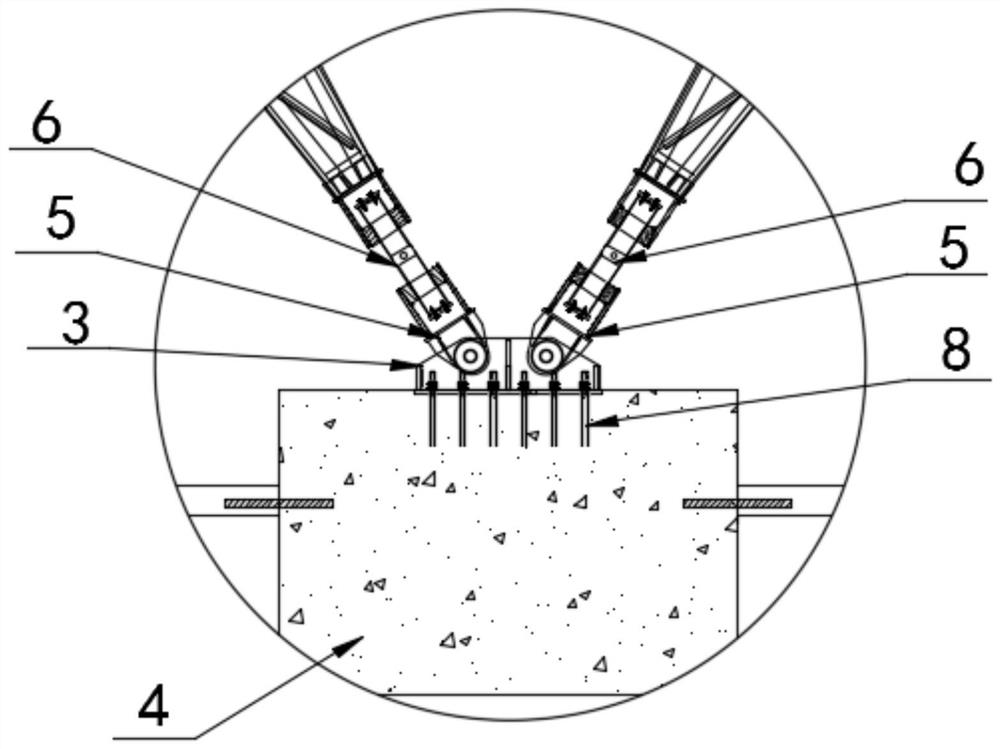

[0028] attached Figures 1 to 6 , an auxiliary supporting structure for the assembly and dismantling of the gantry crane, which includes a steel support 1, an upper hinge seat 2, a lower hinge seat 3 and a concrete ground anchor 4, which is poured and buried on the two sides of the gantry crane. Between the door machine legs 10, the lower hinge seat 3 is arranged on the concrete ground anchor 4, the two door machine legs 10 are respectively provided with the upper hinge seat 2, and the steel support 1 There are two groups, which are respectively connected to the door machine legs 10, one end of which is connected to the upper hinge seat 2, and the other end is connected to the lower hinge seat 3, which is composed of the steel support 1 and door machine legs 10 Triangular support structure. Specifically, the lower hinge seat 3 is anchored on the concrete ground anchor by finishing rolled rebar or long bolts 8 . During construction, the reinforced concrete ground anchor 4 is ...

Embodiment 2

[0032] See attached Figure 7 , an auxiliary supporting structure for assembling and dismantling of a gantry crane. The difference between this embodiment 2 and the above-mentioned embodiment 1 is that it also includes an embedded part 9, which is pre-embedded on the concrete ground anchor 4 , the lower hinge seat 3 is welded and fixed to the embedded part 9 .

Embodiment 3

[0034] See attached Figure 8 , an auxiliary support structure for assembling and dismantling of a gantry crane, comprising a steel support 1, an upper hinge seat 2 and an embedded part 9, which is embedded in two legs 10 of the gantry crane Between, the two door machine legs 10 are respectively provided with the upper hinge seat 2, the steel support 1 has two groups, respectively connected with the door machine legs 10, one end of which is connected to the upper The other end of the hinge seat 2 is welded and fixed with the embedded part 9, and the triangular support structure is formed by the steel support part 1 and the door machine leg 10.

[0035] When dismantling, when constructing other structures (such as the bridge body), the embedded parts 9 are arranged in advance. If the dismantling can no longer be carried out at the original position due to construction needs, the upper end of the steel support 1 and the upper hinge seat 2 of the door machine leg 10 will pass thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com