Expansion device

A technology of expansion device and differential pressure valve, which is applied in fluid circulation arrangement, refrigeration components, refrigerators, etc., can solve the problems of increasing the cost of expansion device and rupture of closed space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, an embodiment of the present invention will be described in detail based on an example applied to using CO 2 in the refrigeration cycle.

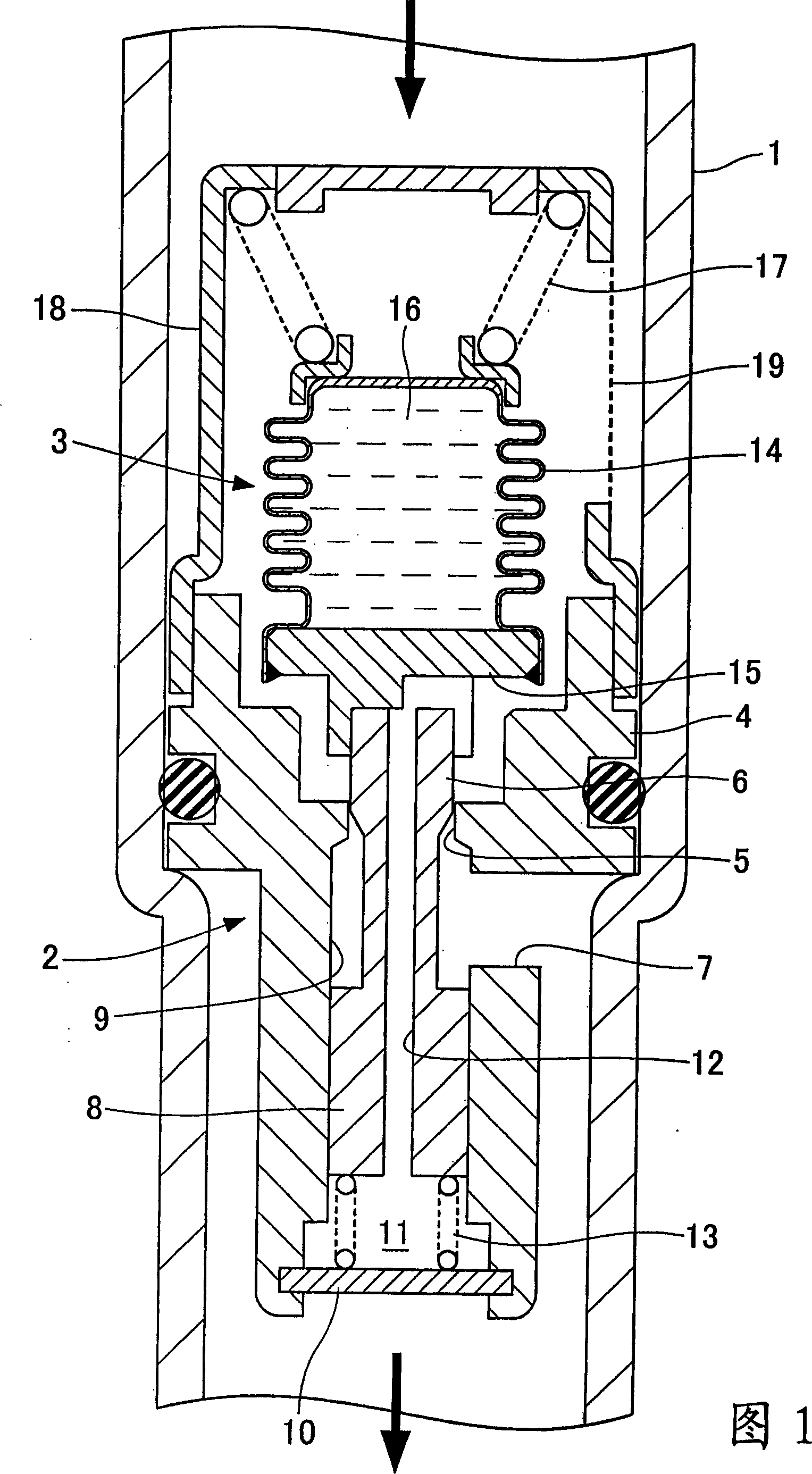

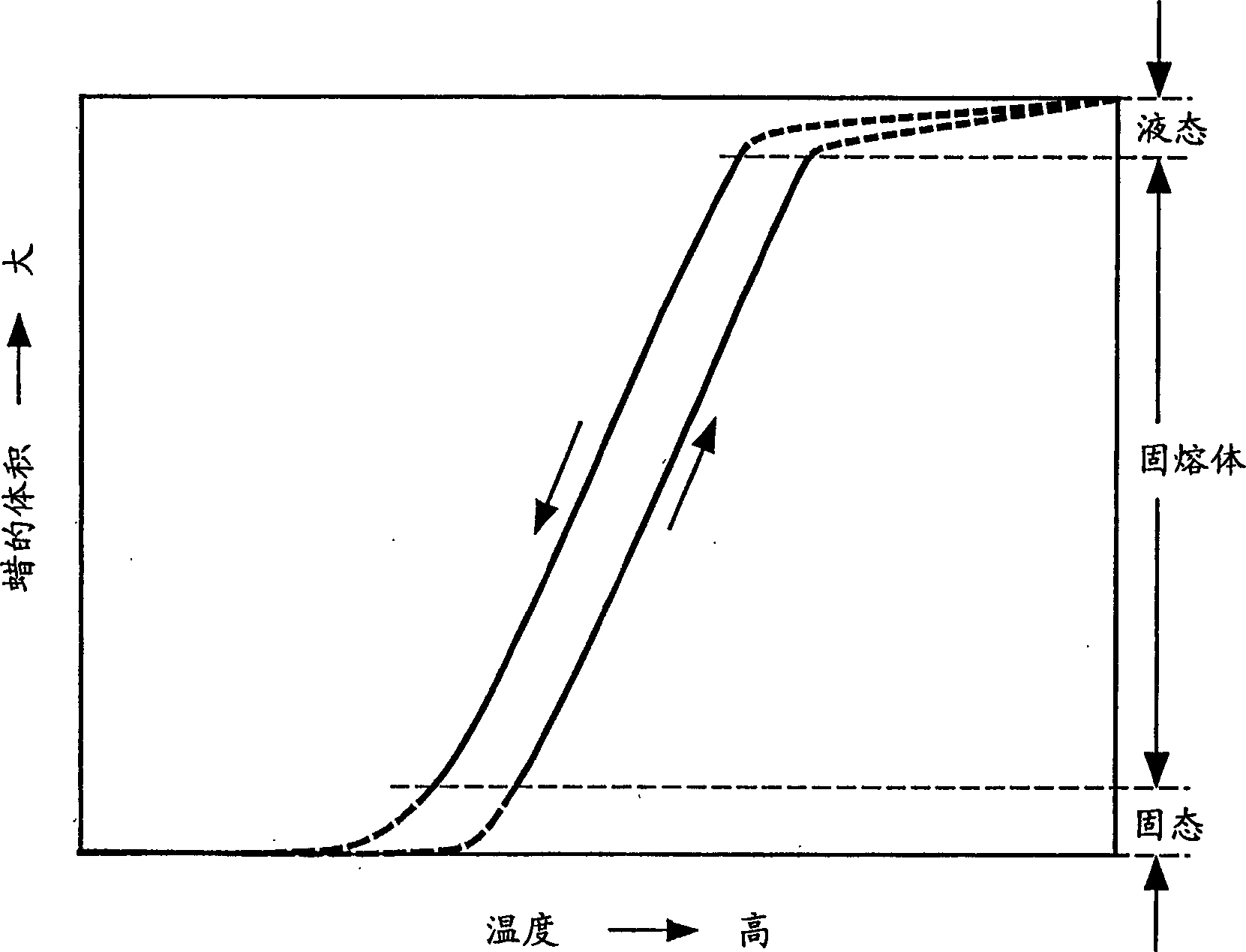

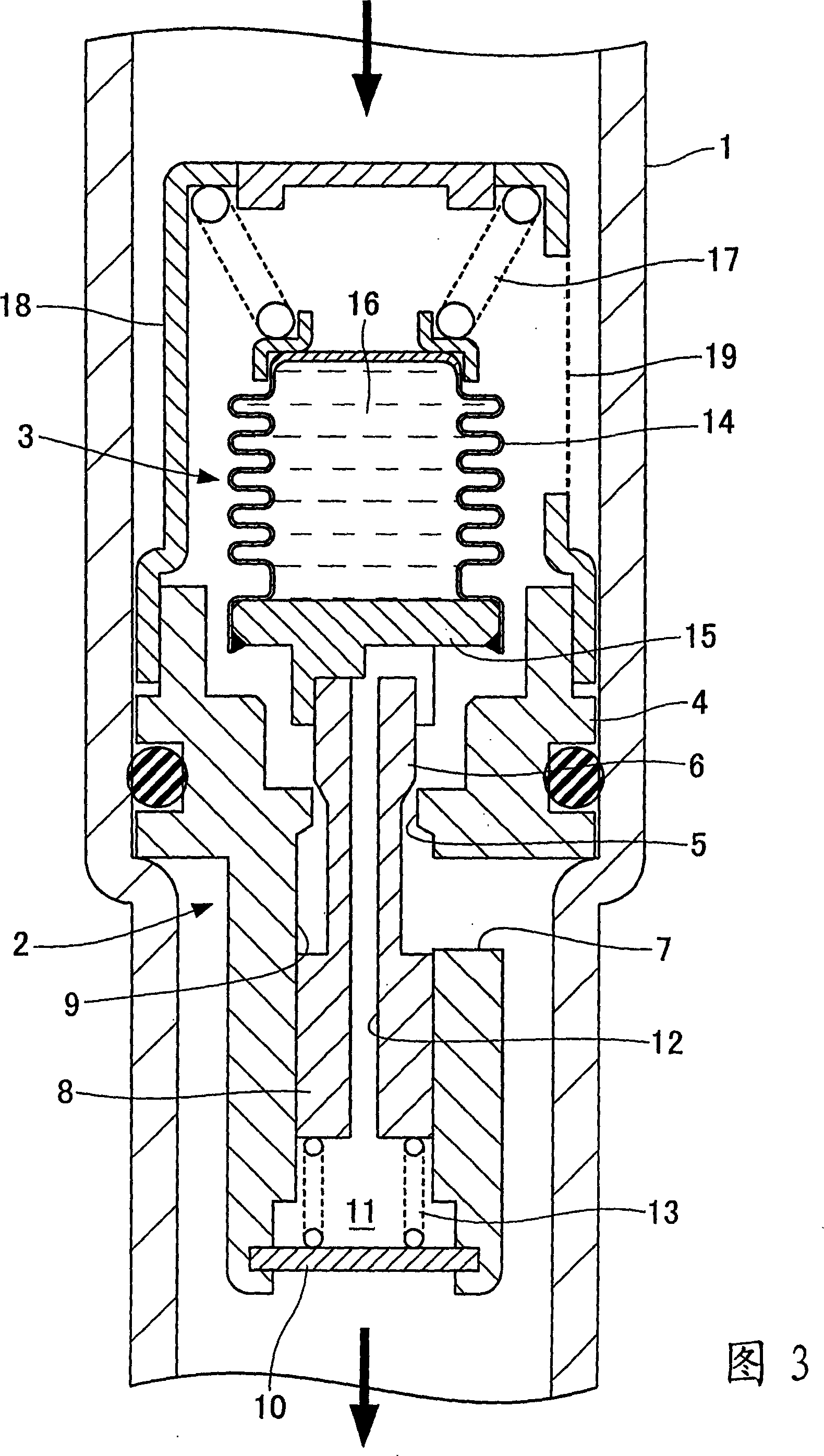

[0030] 1 is a central longitudinal sectional view of an expansion device structure according to a first embodiment of the present invention, and figure 2 is a graph showing the temperature characteristics of the temperature sensing section.

[0031] The expansion device according to the first embodiment is arranged in a pipe 1 between the gas cooler and the evaporator of the refrigeration cycle for circulating the refrigerant. The expansion device includes: a differential pressure valve 2 whose valve lift is controlled according to the pressure difference across the expansion device; a temperature sensing part 3 which further controls the valve lift of the differential pressure valve 2 according to the inlet temperature of the refrigerant. It should be noted that, as shown in Figure 1, the upper part of the pipe 1 corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com