Stepless speed-governing gas spring

A technology of stepless speed regulation and gas spring, which is applied in the direction of spring, spring/shock absorber, gas shock absorber, etc., can solve the problem of not being able to adjust the speed of gas spring, and achieve the effect of pressure relief adjustment and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

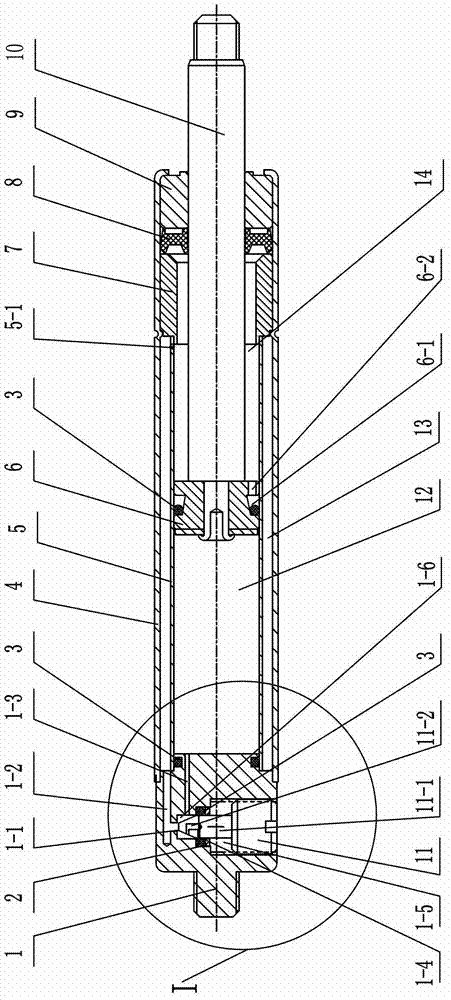

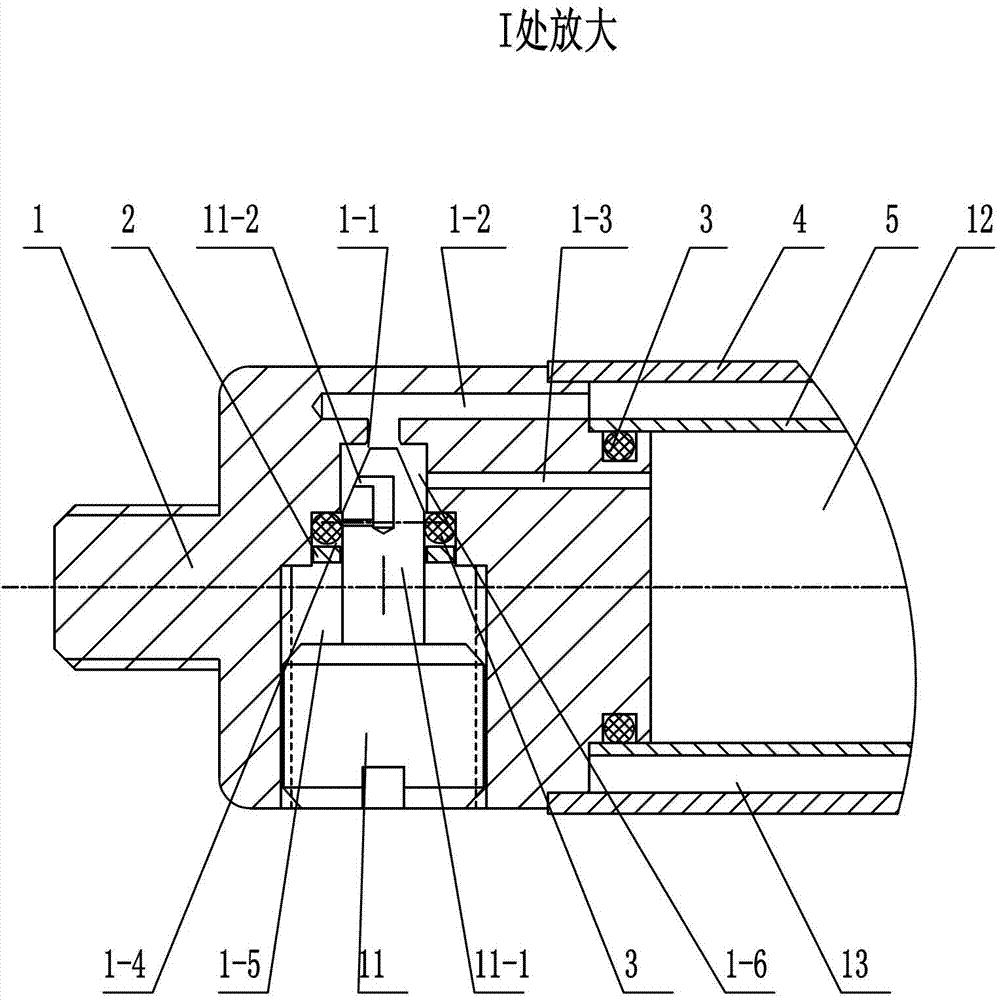

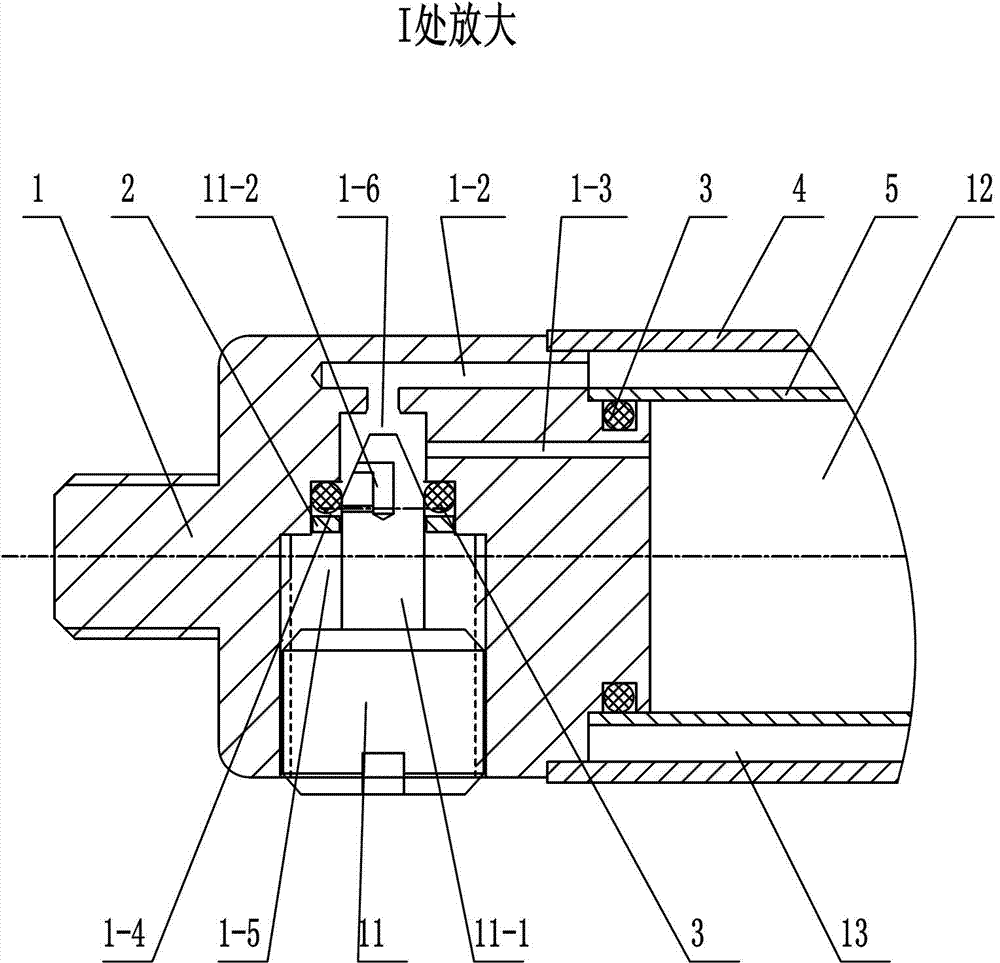

[0013] see Figure 1~3 As shown, the stepless speed-regulating gas spring of the present invention includes a cylinder 4, a piston rod 10, a rear plug 1 and a guide sealing assembly. The guide sealing assembly of the present invention includes the front side of the cylinder 4 and sequentially connected The front guide sleeve 9, the guide seal 8 and the connecting seat 7 fix the guide seal assembly in the cylinder 4, the piston rod 10 is guided and sealed by the guide seal assembly, and the rear plug 1 is fixed on the rear side of the cylinder 4. The rear plug 1 can be welded to the rear side of the cylinder 4. see Figure 1~3 As shown, the rear plug 1 of the present invention is sealed and installed at the outer end of the inner cylinder liner 5, the front part of the rear plug 1 is provided with a sealing groove, the sealing ring 3 is installed in the sealing groove, and the inner cylinder liner 5 is sealed by the sealing ring 3 The inner cylinder liner 5 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com