Coupling-cooling-type pipe fitting flexible electromagnetic forming method and device

An electromagnetic forming and cooling technology, which is applied in the field of flexible electromagnetic forming and devices of coupling cooling pipe fittings, can solve the problems of limited coil specifications and complicated installation, and achieve uniform and flexible force, good effect and lower temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

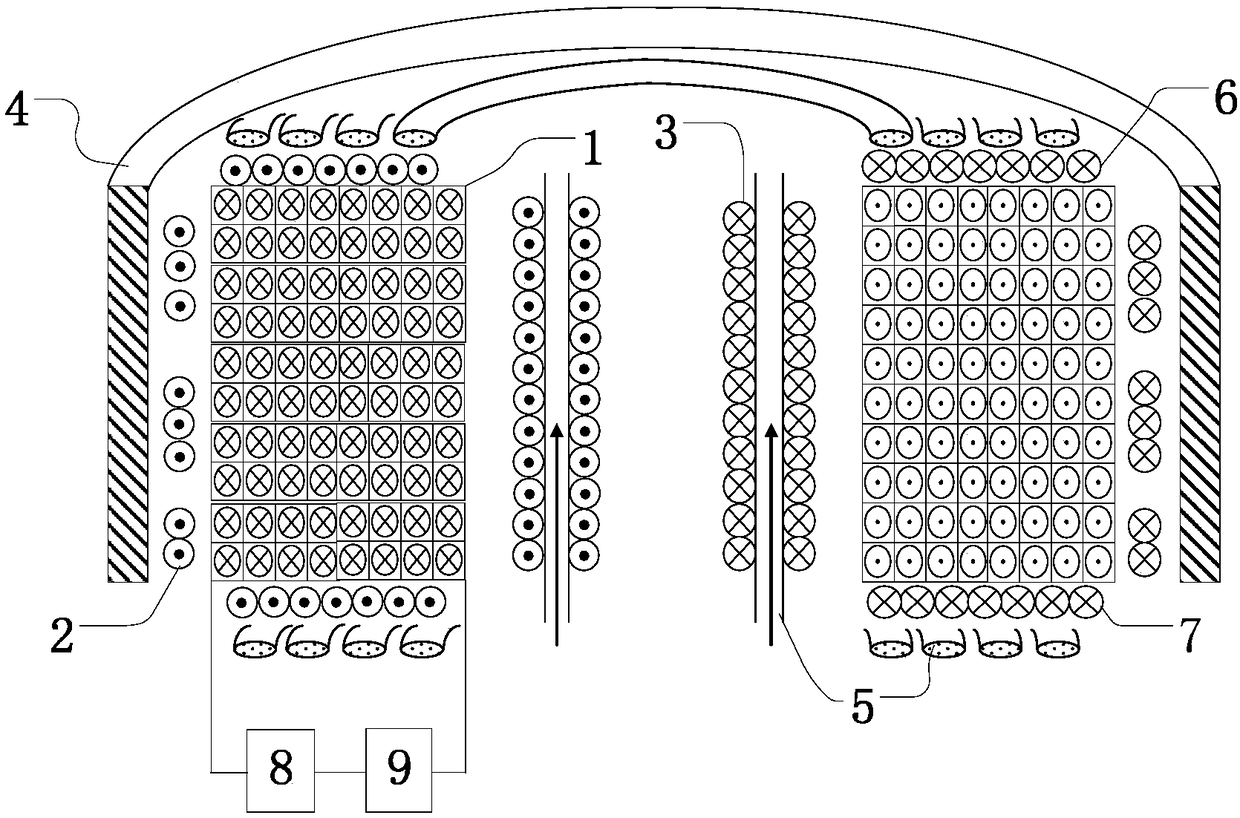

[0071] "Coupled cooling flexible electromagnetic forming of pipe fittings (pipe fitting bulging) with equal spacing and same cross-section flexible electromagnetic force coils and coupled cooling coils" implementation plan:

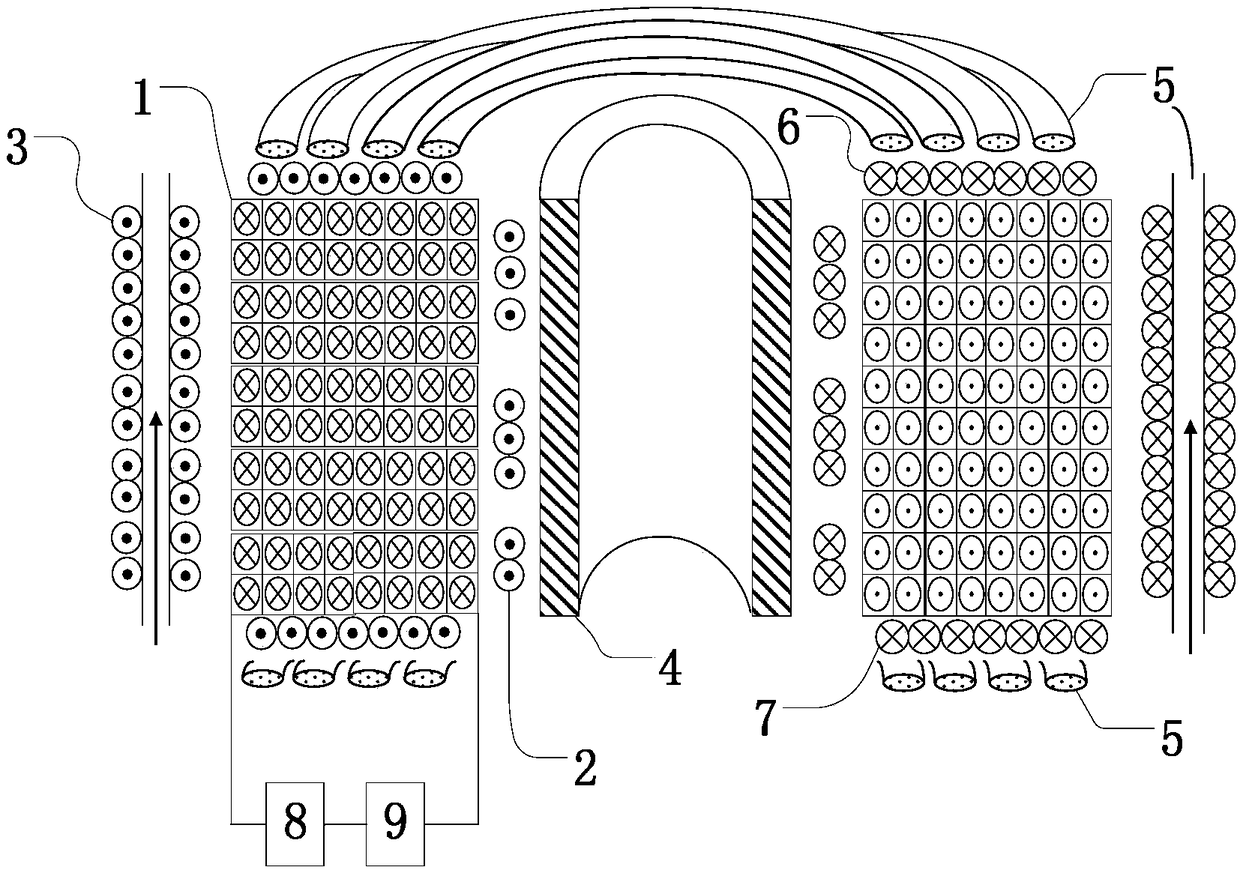

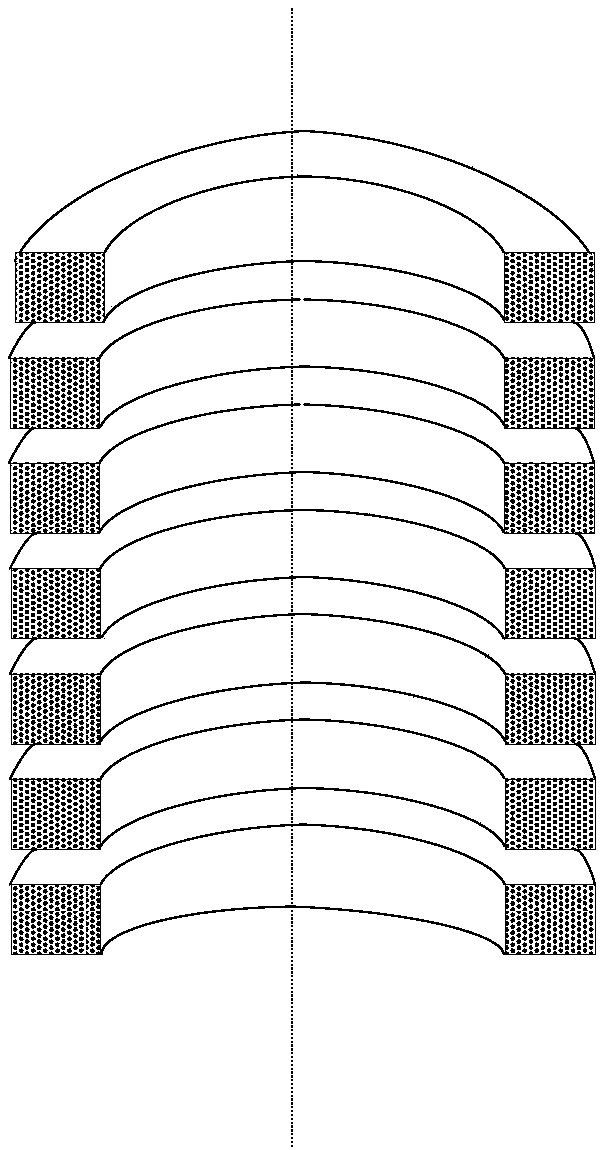

[0072] As shown in Figure 1(a), a copper wire coil group with 8 turns and 10 layers is required (copper wires are insulated from each other, the skeleton inside the coil is an epoxy resin plate, and the outside of the copper coil is wrapped with a new super-strong fiber Zylon for reinforcement). A single-turn 8-layer self-closing flexible electromagnetic force coil with equal spacing and the same cross-section needs to be wound with copper braided wire, which is close to the outer surface of the main coil. The coil winding shape is shown in Figure 3 (a). During the coil coupling process, its shape gradually expands from a gear shape to a ring shape as shown in Figure 2(a). Equally spaced self-closing circular tubular coils wound with copper braided wires...

Embodiment 2

[0074] "Coupled cooling flexible electromagnetic forming of pipe fittings (pipe fitting bulging) with unequal spacing flexible electromagnetic force coils and coupled cooling coils" implementation plan:

[0075] As shown in Figure 1(a), a copper wire coil group with 8 turns and 10 layers is required (copper wires are insulated from each other, the skeleton inside the coil is an epoxy resin plate, and the outside of the copper coil is wrapped with a new super-strong fiber Zylon for reinforcement). A single-turn 8-layer self-closing flexible electromagnetic force coil with unequal spacing that needs to be wound with copper braided wire is close to the outer surface of the main coil. The coil winding shape is shown in Figure 3(b). The flexible electromagnetic force coil and the main coil During the coupling process, its shape gradually expands from a gear shape to a ring shape as shown in Figure 2(b). Equally spaced self-closing circular tubular coils wound with copper braided w...

Embodiment 3

[0077] "Coupled cooling flexible electromagnetic forming of pipe fittings (pipe fitting bulging) with unequal cross-section flexible electromagnetic force coils and coupled cooling coils" implementation plan:

[0078] As shown in Figure 1(a), a copper wire coil group with 8 turns and 10 layers is required (copper wires are insulated from each other, the skeleton inside the coil is an epoxy resin plate, and the outside of the copper coil is wrapped with a new super-strong fiber Zylon for reinforcement). Single-turn 8-layer self-closing flexible electromagnetic force coils of different cross-sections need to be wound with copper braided wires, which are close to the outer surface of the main coil. The coil winding shape is shown in Figure 3(c). The flexible electromagnetic force coil is coupled to the main coil During the process, its shape gradually expands from a gear shape to a ring shape as shown in Figure 2(c). Equally spaced self-closing circular tubular coils wound with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com