Liquid oxygen kerosene pintle injector

A technology of injectors and kerosene, applied in jet propulsion devices, machines/engines, rocket engine devices, etc., can solve problems such as the influence of engine combustion efficiency, the inability to change the injection area, and the effect of fog mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The liquid oxygen kerosene needle injector provided in this application is not only suitable for kerosene liquid oxygen propellant, but also suitable for liquid rocket engines of other liquid-liquid bicomponent propellants.

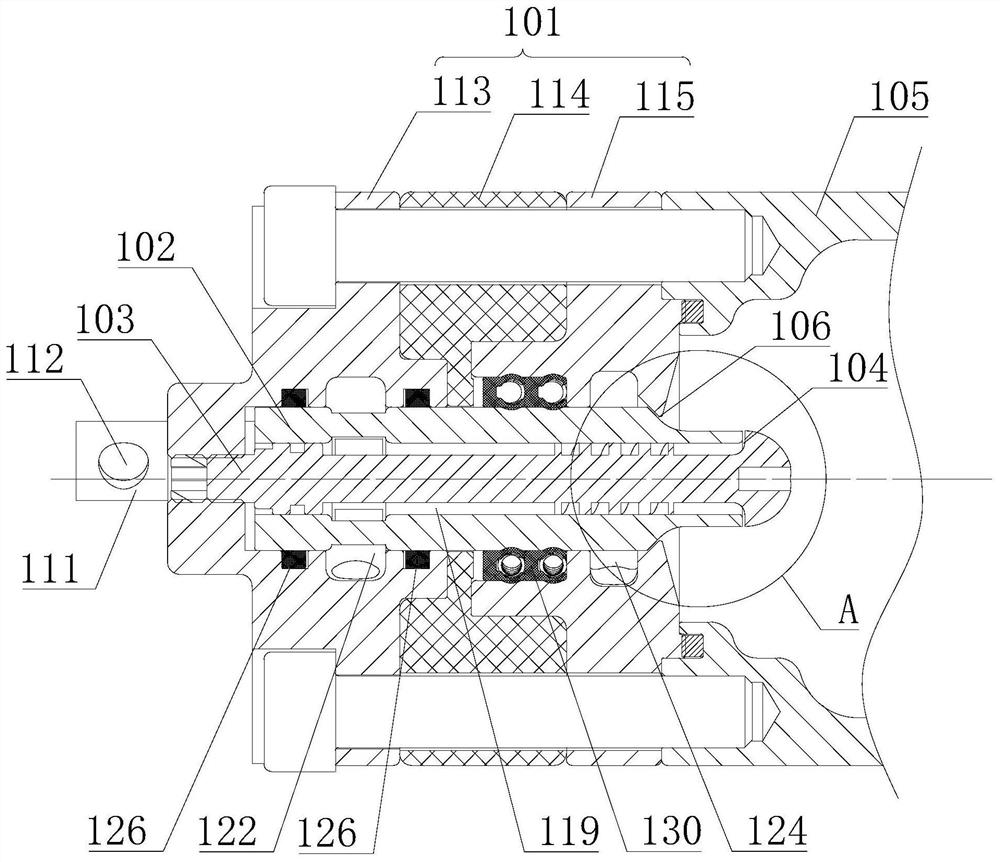

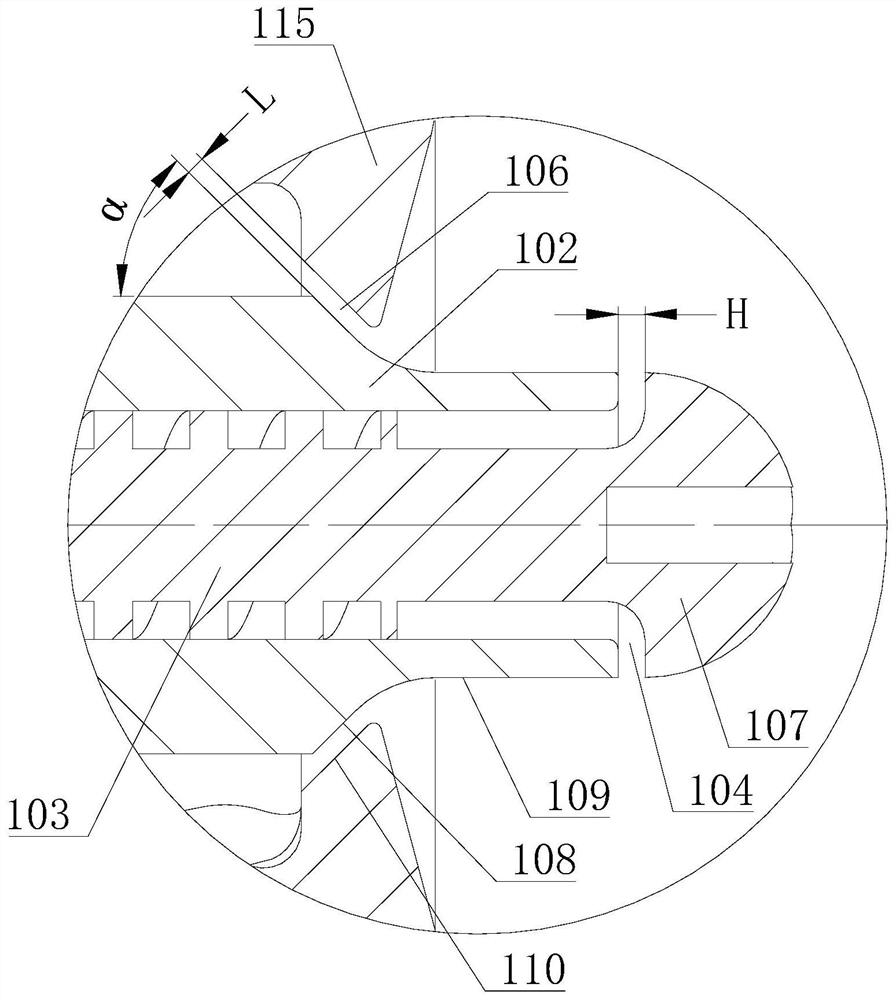

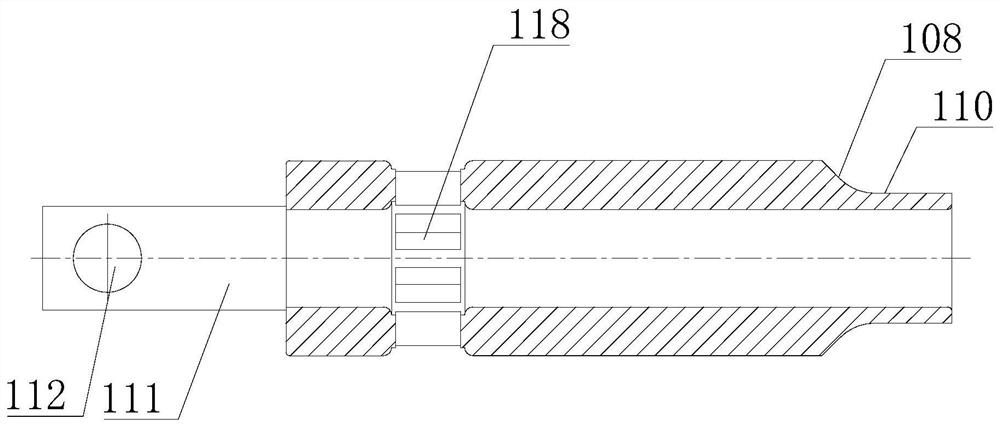

[0044] see Figure 1 to Figure 6 As shown, the liquid oxygen kerosene pintle injector includes a housing 101, an adjustment cylinder 102 and a center rod 103; the adjustment cylinder 102 is sleeved outside the center rod 103, and the first liquid injection outlet is formed between the adjustment cylinder 102 and the center rod 103 104, kerosene flows into the combustion chamber 105 through the first liquid injection outlet 104; the casing 101 is sleeved outside the regulating cylinder 102, and the second liquid spraying exit 106 is formed between the casing 101 and the regulating cylinder 102, and the liquid oxygen flows through the second The liquid injection outlet 106 enters the combustion chamber 105; the kerosene ejected from the first liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com