Power device parallel cooling structure and motor controller applying same

A technology of power device and cooling structure, applied in motor control, control system, cooling/ventilation/heating transformation, etc., can solve the problems of low chip temperature, high chip temperature, redundant heat dissipation conditions of high-power devices, etc. The effect of changing and smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

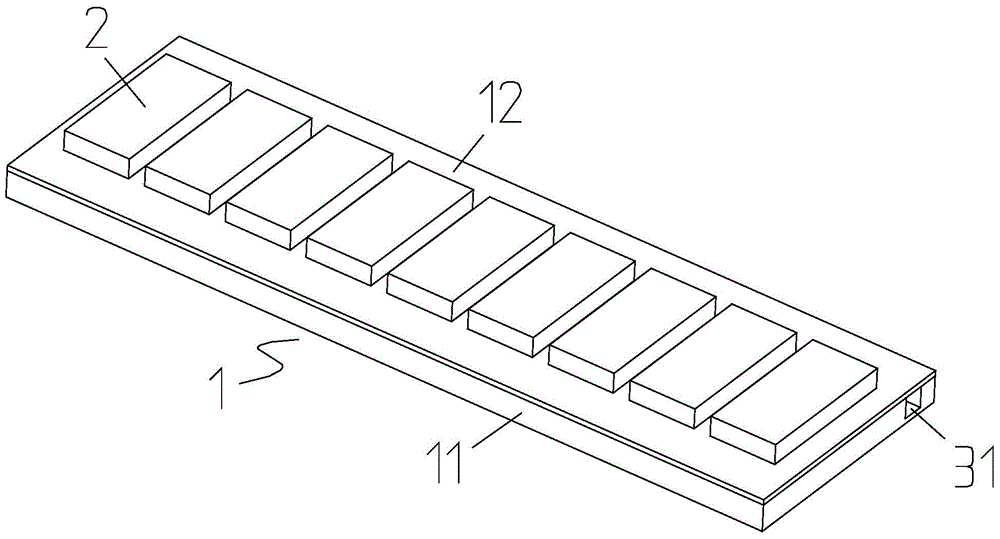

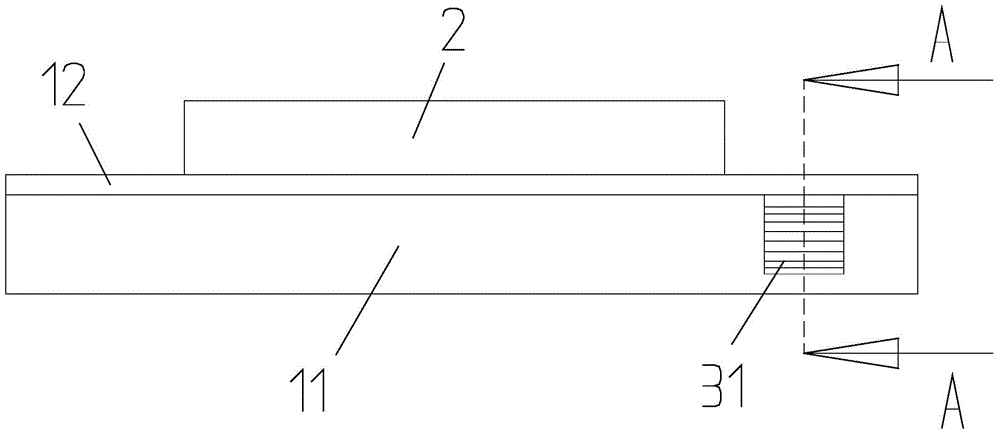

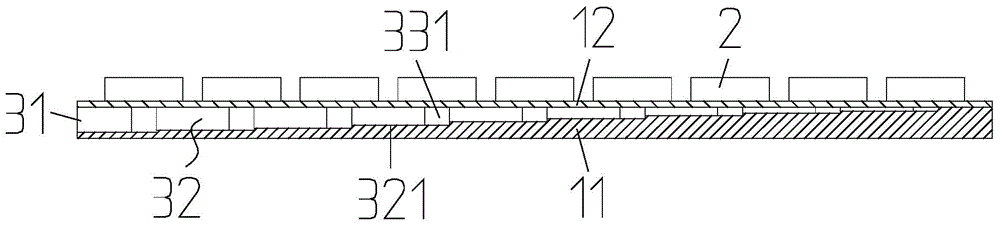

[0034] Embodiment one: if figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, this embodiment is a parallel cooling structure for power devices, including a heat dissipation base 1 and several power devices 2, and several power devices 2 are installed on the heat dissipation base 1 at intervals, and a heat dissipation water channel is arranged inside the heat dissipation base 1 3. The heat dissipation channel 3 includes a water inlet 31, a water inlet channel 32, several branch channels 33, an outlet channel 34 and a water outlet 35. The water inlet 31 is connected to the water inlet channel 32, and the water outlet 35 is connected to the water outlet channel 34. Several The tributary waterways 33 are arranged side by side between the water inlet 32 and the water outlet 34, and the water inlet 32 and the water outlet 34 are connected in parallel by several tributary waterways 33. The cross-sectional area of the water inlet 32 starts from...

Embodiment 2

[0051] Embodiment two: if Figure 8 and Figure 9 As shown, the difference from Embodiment 1 is that: a step portion 122 protrudes downward from the bottom surface of the cover plate 12, and the height of the step portion 122 extending downward from the water inlet 31 gradually becomes larger, and the step portion 122 extends into the Inside the water inlet channel 32 , and the step portions 122 and the diverging steps 6 are arranged in a staggered interval, so that the cross-sectional area of the water inlet channel 32 gradually decreases from the water inlet 31 .

[0052] The parallel cooling structure of the power devices in the embodiment will be further described by means of a simulation test. In this embodiment, the number of branch water channels 33 is also nine.

[0053] Simulation test:

[0054] 1. Material property: 25℃ water.

[0055] 2. Boundary conditions and solution settings

[0056] The inlet flow rate is 30L / min, and the average relative pressure at the ...

Embodiment 3

[0065] Embodiment three: as Figure 10 and Figure 11 As shown, this embodiment is a motor controller, including a controller box 4, a heat dissipation base 1, a control circuit board 5 and several power modules 2, the heat dissipation base 1 is arranged inside the controller box 4, and several power devices 2 They are respectively arranged at intervals on the heat dissipation base 1, and the heat dissipation water channel 3 is arranged in the heat dissipation base 1, and the control circuit board 5 is installed in the controller box 4, and each power module 2 is electrically connected with the control circuit board 5. Together, the cooling channel 3 includes a water inlet 31, a water inlet channel 32, several branch channels 33, an outlet channel 34 and a water outlet 35, the water inlet 31 communicates with the water inlet channel 32, the water outlet 35 communicates with the water outlet channel 34, and several The tributary waterways 33 are arranged side by side between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com