Electronic control variable-damping rotation hydraulic damper

A hydraulic damper and variable technology, applied in the direction of liquid shock absorber, shock absorber, shock absorber, etc., can solve the problems of insufficient compact structure of proportional servo control scheme and high cost of proportional valve control, and achieve compact structure and convenient The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

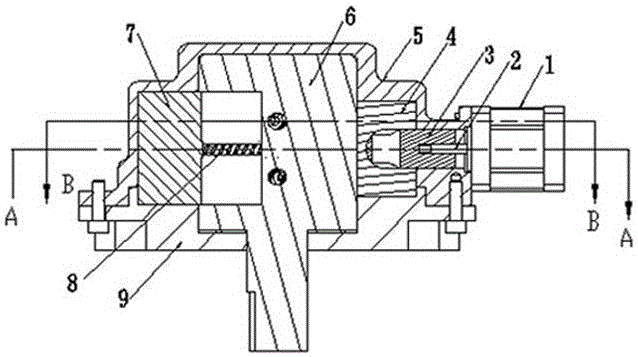

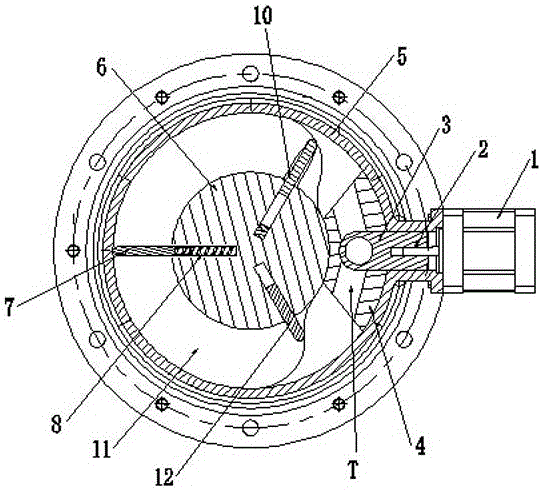

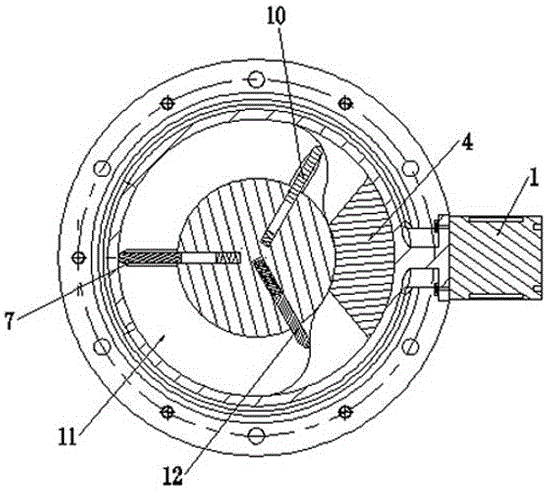

[0022] combine Figure 1-Figure 4 As shown, the present invention is further described as follows: an electronically controlled variable damping rotary hydraulic damper, including 3 vanes, a valve body 4, a valve core 3, a shaft 6, a housing 5, an end cover 9, a compression spring 8, a motor 1. The three blades are the first blade 7, the second blade 12, and the third blade 10. The end cover 9 is connected to the housing 5. The shaft 6 is located in the cavity between the end cover and the housing. The input of the shaft 6 protruding from the end cap,

[0023] A guide rail 11 is processed on the shell and the bottom cover. The minimum diameter of the guide rail 11 is equal to the outer diameter of the shaft. The maximum diameter of the guide rail 11 is equal to the diameter of the inner cavity of the housing. The arc with the largest diameter and the concentric arc with the smallest diameter are connected by a transition curve;

[0024] The first blade 7, the second blade 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com