Spring operation mechanism used for high-voltage switch

An operating mechanism and high-voltage switch technology, applied to the power device inside the switch, etc., can solve the problems of poor structural stability, high manufacturing cost, and many parts, and achieve low manufacturing cost, simple and stable structure, and few parts. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

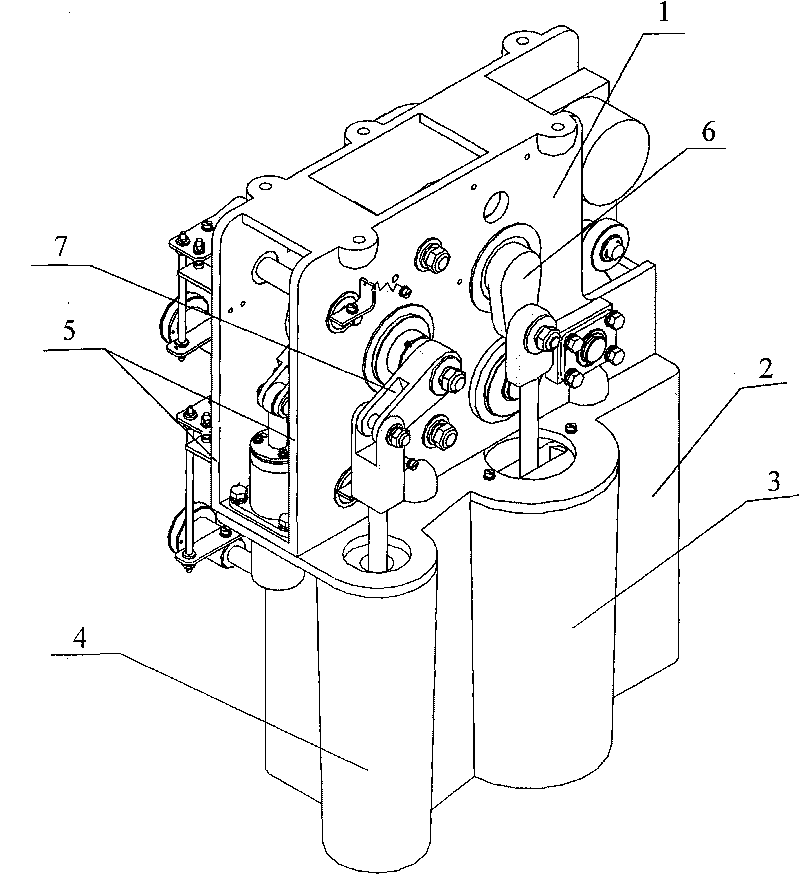

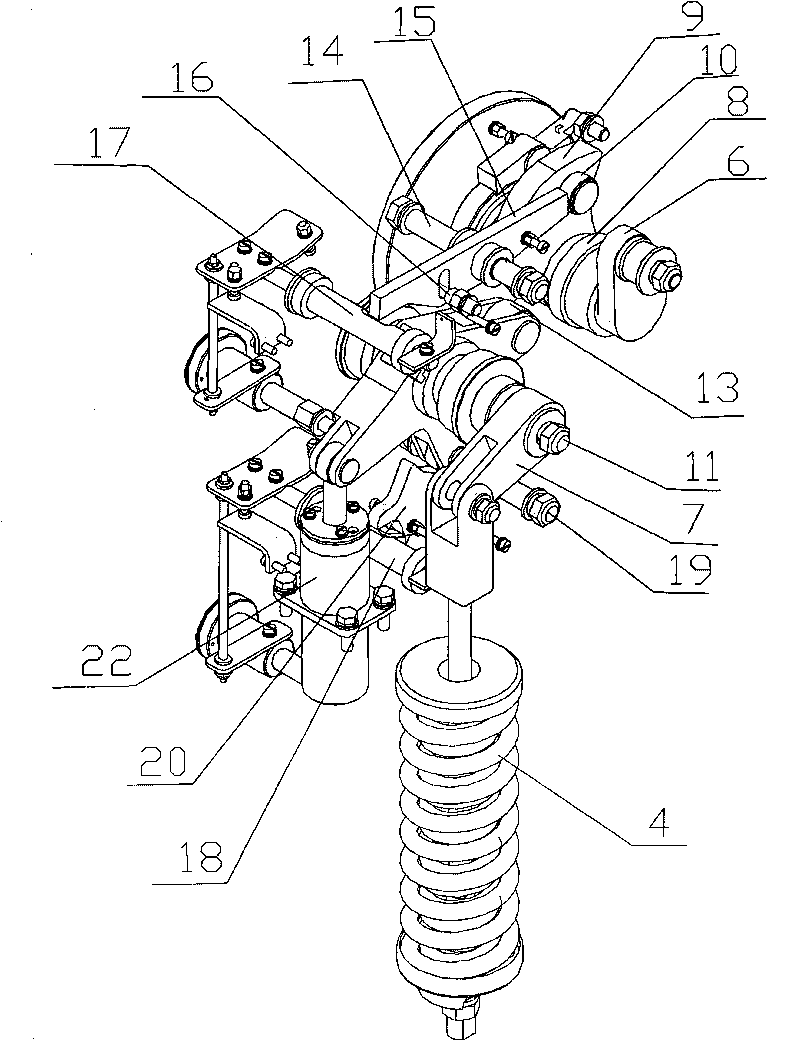

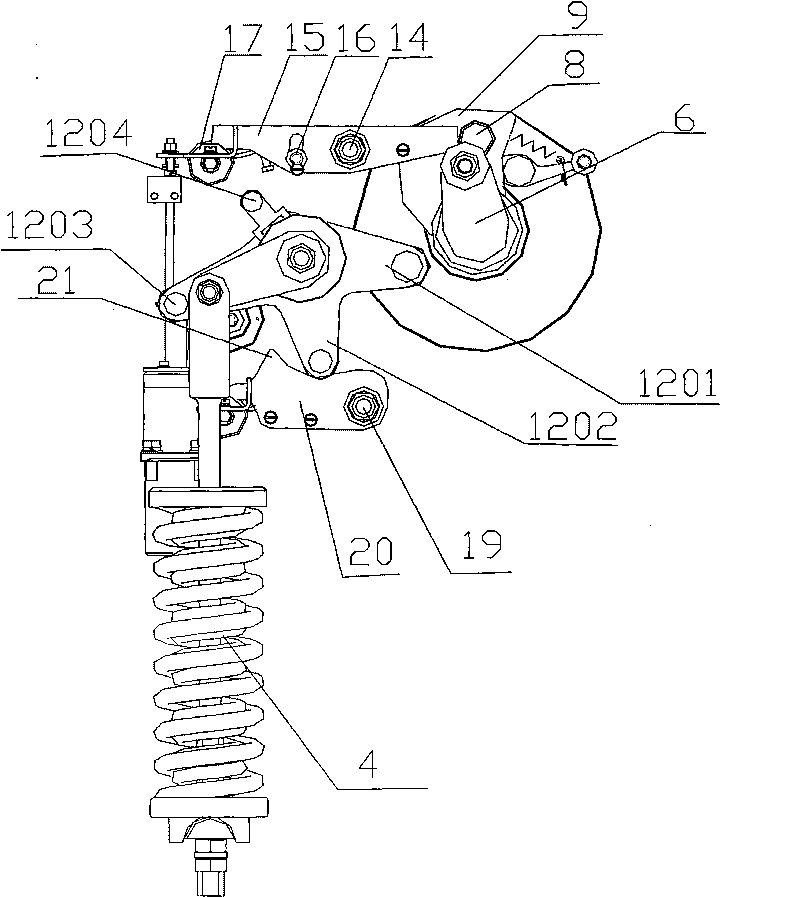

[0020] refer to figure 1 figure 2 , image 3 , is a spring operating mechanism for a high-voltage switch, mainly including a frame 1 and a spring frame 2 fixed below the frame 1 . Both the frame 1 and the spring frame 2 are integral cast aluminum frames. The frame 1 has two parallel vertical plates 5, vertically running through the two vertical plates 5, there are mutually parallel energy storage shafts 8, output shafts 11, closing semi-shafts 17, opening semi-shafts 18, and first pawl shafts. 14. A plurality of shafts such as the second detent shaft 19 . The spring frame is provided with an energy storage spring 3 and an opening spring 4, both of which are compression springs. The outer end of the energy storage shaft is movably connected to the energy storage spring 3 through the first crank 6 , and the outer end of the output shaft is movably connected to the energy storage spring 4 through the second crank 7 .

[0021] Between the two vertical plates 5, a closing cam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com