Piston type four-way reversing valve

A four-way reversing valve, piston-type technology, applied in multi-way valves, valve details, valve devices, etc., can solve problems such as oil film piston stuck, avoid dry friction, increase service life, and move flexibly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

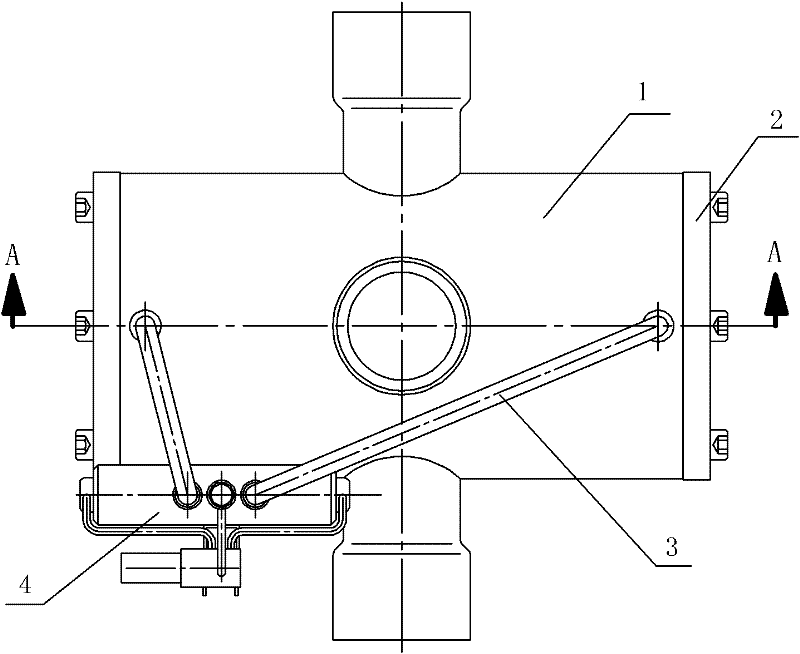

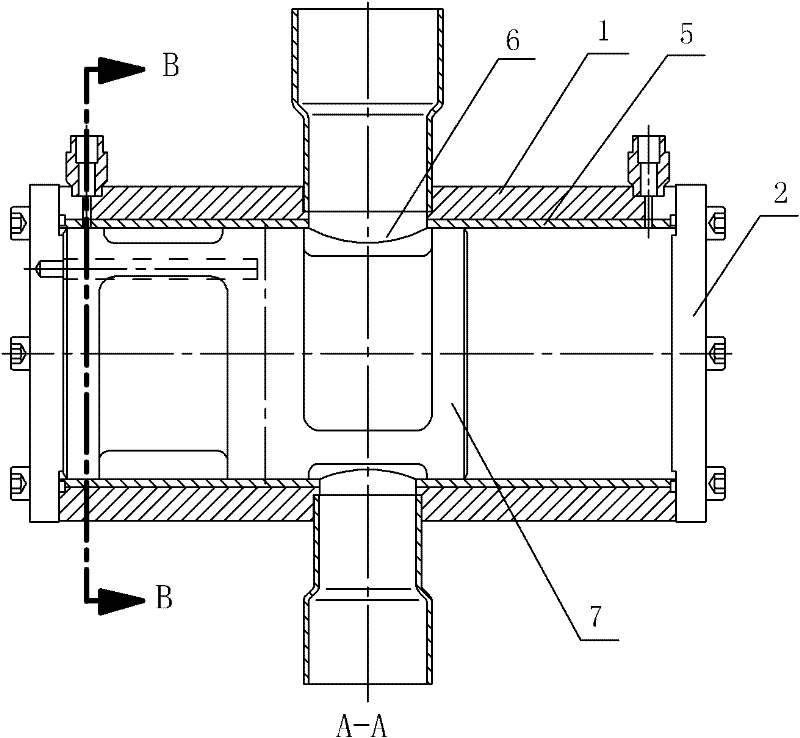

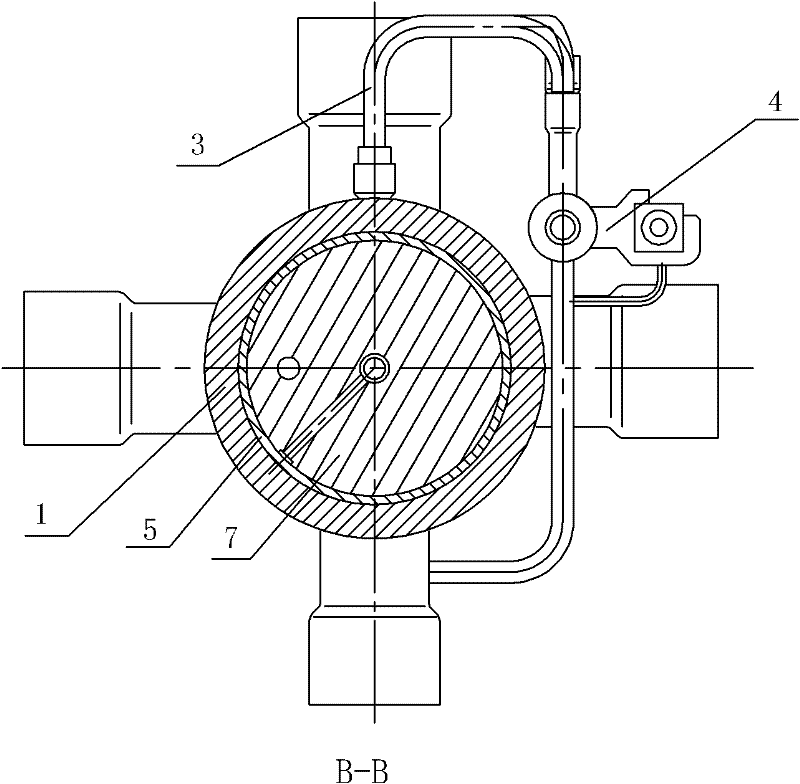

[0030] Embodiment one: if Figure 1 to Figure 6 As shown, the present invention is mainly composed of a main valve and a pilot valve 4. The pilot valve 4 communicates with the cavity of the main valve through the air guide tube 3. The main valve includes a valve body 1, a piston 7 arranged in the valve body, and a piston 7 arranged on both sides of the valve body. Two end caps 2 at the end, four valve ports 6 are set on the valve body 1, and the piston 7 is composed of two I-shaped components rotated and staggered by 90 degrees to form a whole. The lubricating sleeve 5, the sleeve body 8 of the lubricating sleeve 5 is a bobbin made of copper-based alloy material, the sleeve body 8 is fixedly connected with the valve body 1, and the sleeve body 8 is provided with four through holes 9, and these through holes 9 are connected with the valve body. The openings 6 have equal diameters, corresponding positions and are connected. A plurality of oil pockets 10 are also arranged on the ...

Embodiment 2

[0031] Embodiment two: if Figure 1 ~ Figure 3 as well as Figure 7 , Figure 8 As shown, the present invention is mainly composed of a main valve and a pilot valve 4. The pilot valve 4 communicates with the cavity of the main valve through the air guide tube 3. The main valve includes a valve body 1, a piston 7 arranged in the valve body, and a piston 7 arranged on both sides of the valve body. Two end caps 2 at the end, four valve ports 6 are set on the valve body 1, and the piston 7 is composed of two I-shaped components rotated and staggered by 90 degrees to form a whole. The lubricating sleeve 5, the sleeve body 8 of the lubricating sleeve 5 is a bobbin made of cast iron material, the sleeve body 8 is fixedly connected with the valve body 1, and the sleeve body 8 is provided with four through holes 9, and these through holes 9 are connected with the valve port 6 The diameters are equivalent, the positions are corresponding and connected, and a plurality of oil pockets 1...

Embodiment 3

[0032] Embodiment three: as Figure 1 ~ Figure 3 as well as Figure 9 ~ Figure 11 As shown, the present invention is mainly composed of a main valve and a pilot valve 4. The pilot valve 4 communicates with the cavity of the main valve through the air guide tube 3. The main valve includes a valve body 1, a piston 7 arranged in the valve body, and a piston 7 arranged on both sides of the valve body. Two end caps 2 at the end, four valve ports 6 are set on the valve body 1, and the piston 7 is composed of two I-shaped components rotated and staggered by 90 degrees to form a whole. The lubricating sleeve 5, the sleeve body 8 of the lubricating sleeve 5 is rolled from a copper sheet, the sleeve body 8 is fixedly connected with the valve body 1, and the sleeve body 8 is provided with four through holes 9, and these through holes 9 are connected with the valve port 6 The diameters are equivalent, the positions are corresponding and connected, and a plurality of oil pockets 10 are al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com