Fast stone breaking device for rare earth machining

A stone, fast technology, applied in the field of rapid stone crushing equipment for rare earth processing, can solve the problems of time-consuming and labor-intensive crushing, easy to get stuck in crushed volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

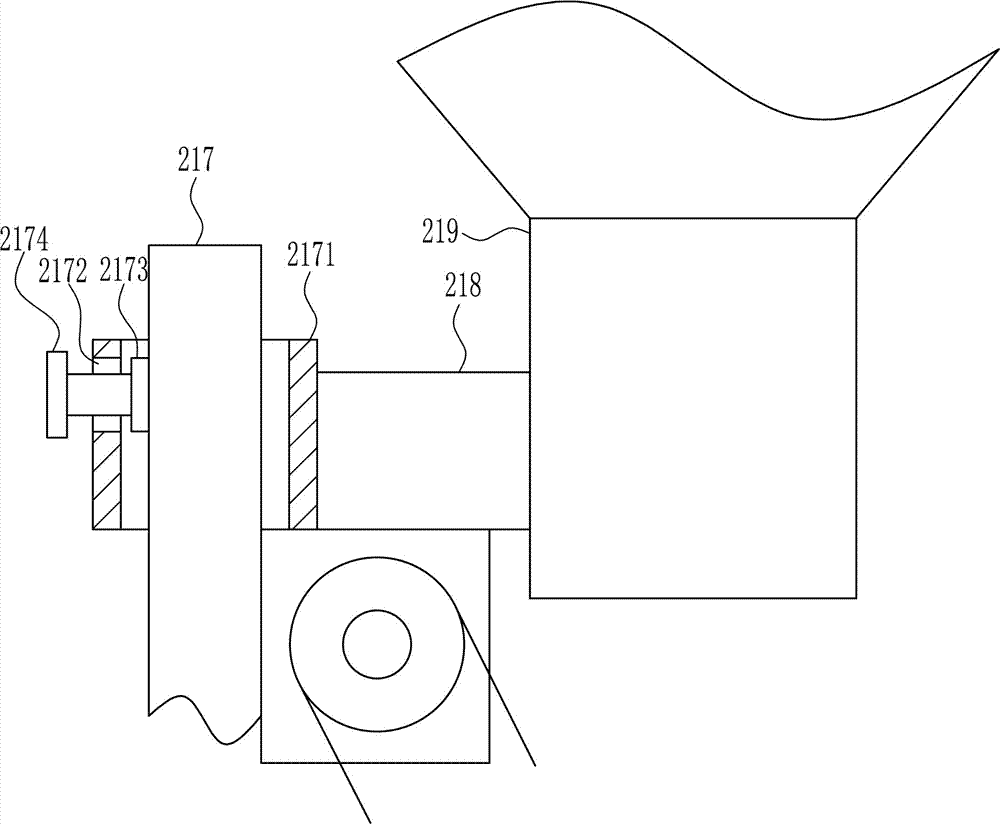

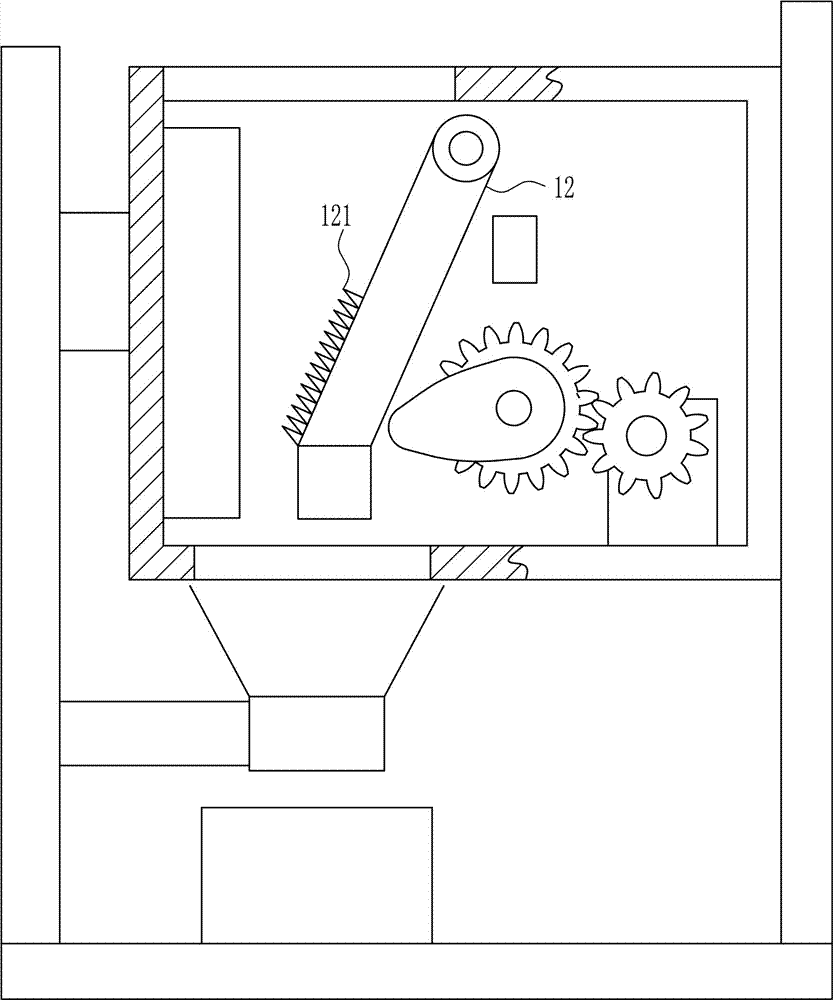

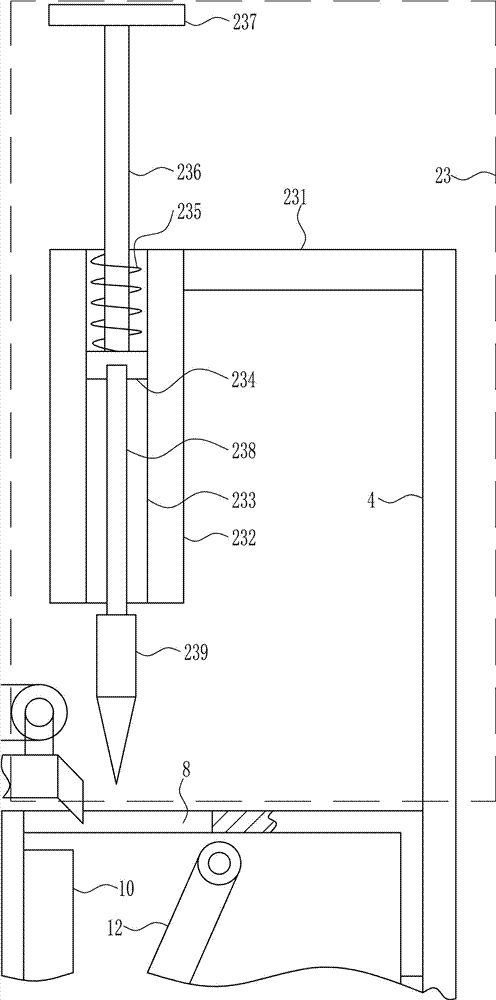

[0038] A rapid stone breaking equipment for rare earth processing, such as Figure 1-8 As shown, it includes a bottom plate 1, a collection box 2, a first supporting plate 3, a second supporting plate 4, a first connecting block 5, a first hopper 6, a breaking box 7, a breaking block 10, a first rotating shaft 11, The movable plate 12, the weight 13, the first stopper 14, the first motor 15, the first gear 16, the second shaft 17, the second gear 18, the cam 19 and the second connecting block 20, placed on the upper middle left of the bottom plate 1 There is a collection box 2, a first support plate 3 is installed on the left side of the bottom plate 1 by welding, a second support plate 4 is installed on the right side of the bottom plate 1 by welding, and the lower right side of the first support plate 3 is welded The first connecting block 5 is installed by welding, the first hopper 6 is installed on the right end of the first connecting block 5 by welding, and the breaking b...

Embodiment 2

[0040] A rapid stone breaking equipment for rare earth processing, such as Figure 1-8 As shown, it includes a bottom plate 1, a collection box 2, a first supporting plate 3, a second supporting plate 4, a first connecting block 5, a first funnel 6, a breaking box 7, a breaking block 10, a first rotating shaft 11, The movable plate 12, the weight 13, the first stopper 14, the first motor 15, the first gear 16, the second shaft 17, the second gear 18, the cam 19 and the second connecting block 20, placed on the upper middle left of the bottom plate 1 There is a collection box 2, a first support plate 3 is installed on the left side of the bottom plate 1 by welding, a second support plate 4 is installed on the right side of the bottom plate 1 by welding, and the lower right side of the first support plate 3 is welded The first connecting block 5 is installed by welding, the first hopper 6 is installed on the right end of the first connecting block 5 by welding, and the breaking b...

Embodiment 3

[0043] A rapid stone breaking equipment for rare earth processing, such as Figure 1-8 As shown, it includes a bottom plate 1, a collection box 2, a first supporting plate 3, a second supporting plate 4, a first connecting block 5, a first funnel 6, a breaking box 7, a breaking block 10, a first rotating shaft 11, The movable plate 12, the weight 13, the first stopper 14, the first motor 15, the first gear 16, the second shaft 17, the second gear 18, the cam 19 and the second connecting block 20, placed on the upper middle left of the bottom plate 1 There is a collection box 2, a first support plate 3 is installed on the left side of the bottom plate 1 by welding, a second support plate 4 is installed on the right side of the bottom plate 1 by welding, and the lower right side of the first support plate 3 is welded The first connecting block 5 is installed by welding, the first hopper 6 is installed on the right end of the first connecting block 5 by welding, and the breaking b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com