Medium-pressure high-speed rotating connector

A high-speed rotation, medium-pressure technology, applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing components, etc., can solve the problems of frequent replacement, joint damage, waste of material and financial resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

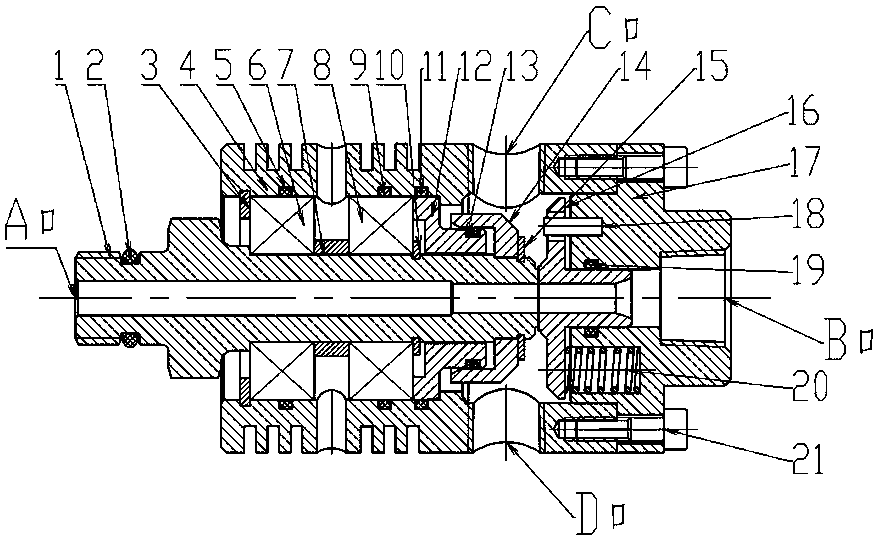

[0021] Such as figure 1 As shown, a medium-pressure high-speed rotary joint includes a housing 4, one end of the housing 4 is fixedly connected with an end cover 17, and a static sealing ring 16 is connected to the inner side of the end cover 17 with a clearance fit, and a rotating joint is connected with the relative rotation in the housing 4. Shaft 1, the inner end surface of the rotating shaft 1 and the inner end surface of the static sealing ring 16 are in airtight contact and communicated, the inner wall of the housing 4 is connected with a sealing spacer 12, the rotating shaft 1 passes through the middle of the sealing spacer 12, and the sealing spacer 12 faces The side where the static sealing ring 16 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com