Invisible pressing expansion screw

A compact and invisible technology, applied in the direction of connecting components, pins, mechanical equipment, etc., can solve the problems of pedestrians falling, puncturing car tires, unable to form a flat environment, etc., to achieve the effect of maintaining flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

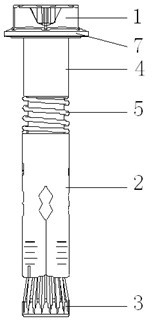

[0026] Embodiment 1: The main body bolt 1 is integrally formed, the upper casing 4, the compression spring 5, and the expansion tube 2 are sequentially sleeved on the upper part of the screw with a larger diameter of the main body bolt 1, and the frustum-shaped expansion head 3 The internal thread is spirally matched with the external thread of the screw with a smaller diameter at the lower part of the main body bolt 1, such as Figure 5 shown. The structure of the first embodiment is suitable for the case where the diameter of the main body bolt 1 is small, and at this time, there is no special requirement for the equipment for processing the main body bolt 1 with a stepped screw.

Embodiment 2

[0027] Embodiment 2: The stepped screw rod with larger diameter on the upper part of the main body bolt 1 and smaller diameter on the lower part is formed in this way, and an inner sleeve 6 is sleeved on the upper part of the screw rod with uniform diameter, and the inner sleeve 6 is equal to increasing the main body bolt. 1. The diameter of the upper screw; the upper sleeve 4, the compression spring 5 and part of the expansion tube 2 are then sleeved on the inner sleeve 6, and the internal thread of the frustum-shaped expansion head 3 is connected to the lower part of the main body bolt 1 Spiral fit with external thread, such as Figure 8 shown. The structure of the second embodiment is suitable for the case where the diameter of the main body bolt 1 is larger. If the diameter of the main body bolt 1 is larger, directly processing the main body bolt 1 with a stepped screw requires relatively large-scale equipment. In order to save equipment investment, at the same time Energ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com