Silencer with variable damp characteristics

A technology of damping characteristics and mufflers, which is applied in the direction of mufflers, machines/engines, mechanical equipment, etc., and can solve problems that have not been adopted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

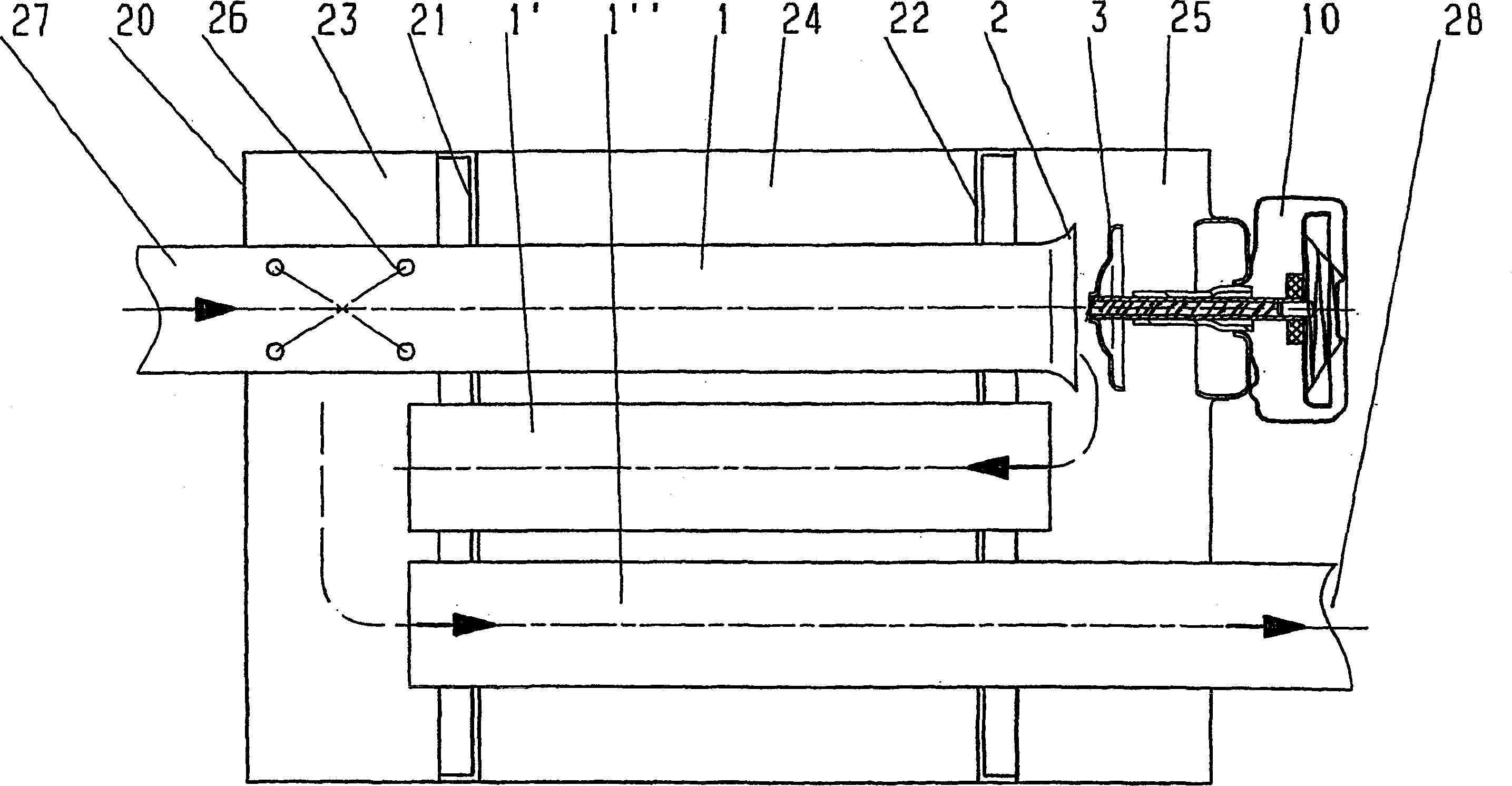

[0032] 1 and 2 both show schematically and in section an anechoic chamber 20 whose interior is divided into three chambers 23 , 24 , 25 by transverse partition members 21 , 22 . A pipe 27 brings the exhaust gas into the anechoic chamber 20; a pipe 28 takes the exhaust gas out of the anechoic chamber 20 again.

[0033] Inside the anechoic chamber 20, three pipes 1, 1', 1" carrying the exhaust gases can be seen. In the immediate vicinity of the first chamber 23, the pipes 1 have perforations 26 through which the exhaust gases can escape.

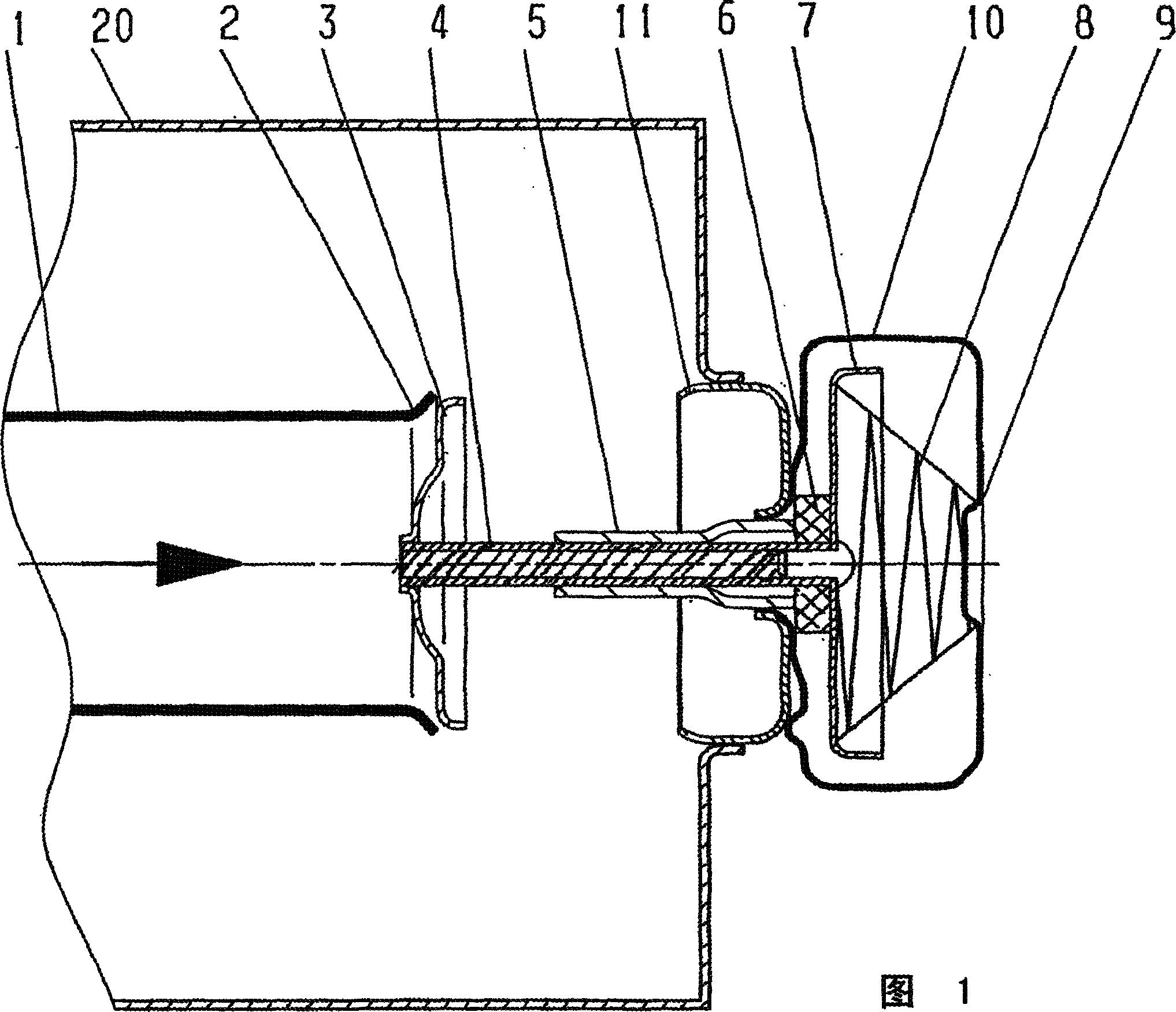

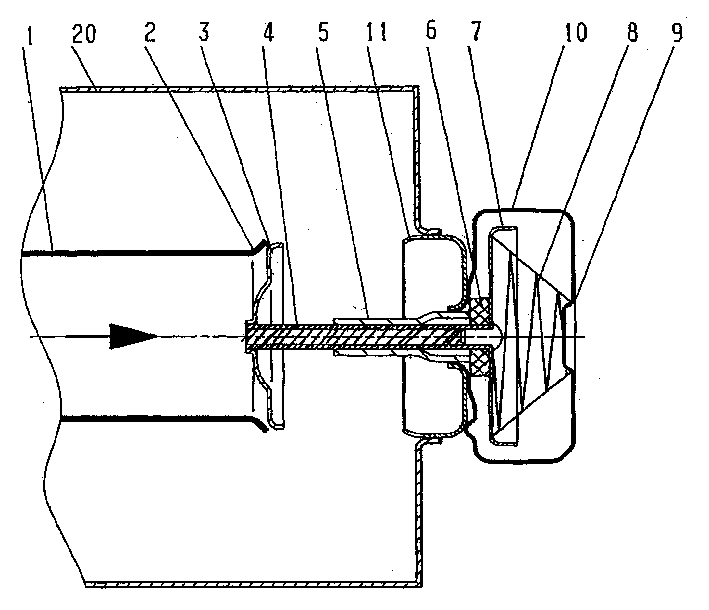

[0034] As shown enlarged in FIG. 1 , the end 2 of the first exhaust gas line 1 is conically widened. A valve disk 3 , which is also conical, closes off the end 2 of the line 1 . The valve disc 3 is mounted on a guide rod 4 , which guides movement in a guide sleeve 5 . The guide bush 5 is held by a fitting 11 airtightly mounted on the wall of the anechoic chamber 20 . Outside the anechoic chamber 20, a valve housing 10 can be seen. In the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com