Novel high-pressure air charging nozzle

An inflatable nozzle, high-pressure technology, applied in the direction of functional valve types, control valves, engine components, etc., can solve the problems of volume and weight that cannot meet space flight, can not meet inflation pressure, and single function of inflatable nozzles. Small quantity, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

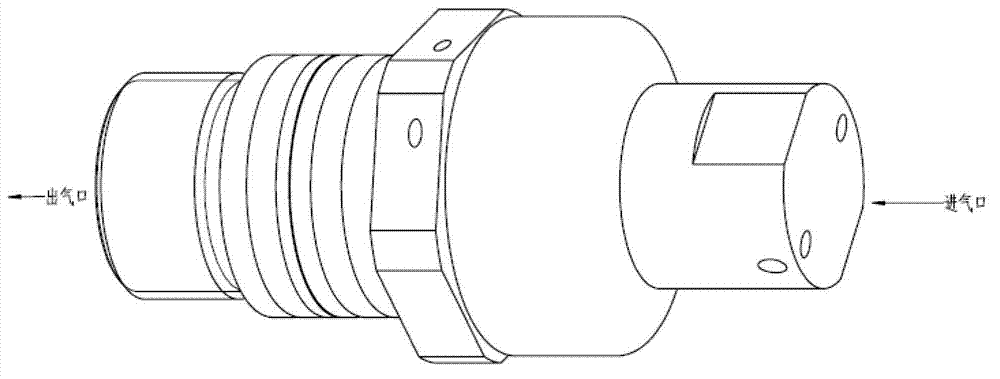

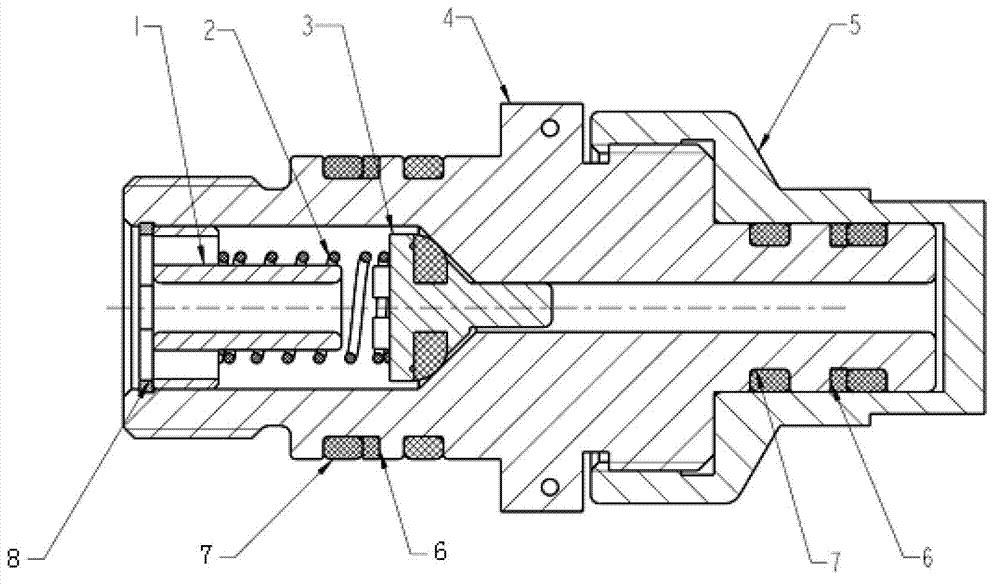

[0020] A new type of high-pressure inflation nozzle provided by the present invention is introduced below in conjunction with the accompanying drawings:

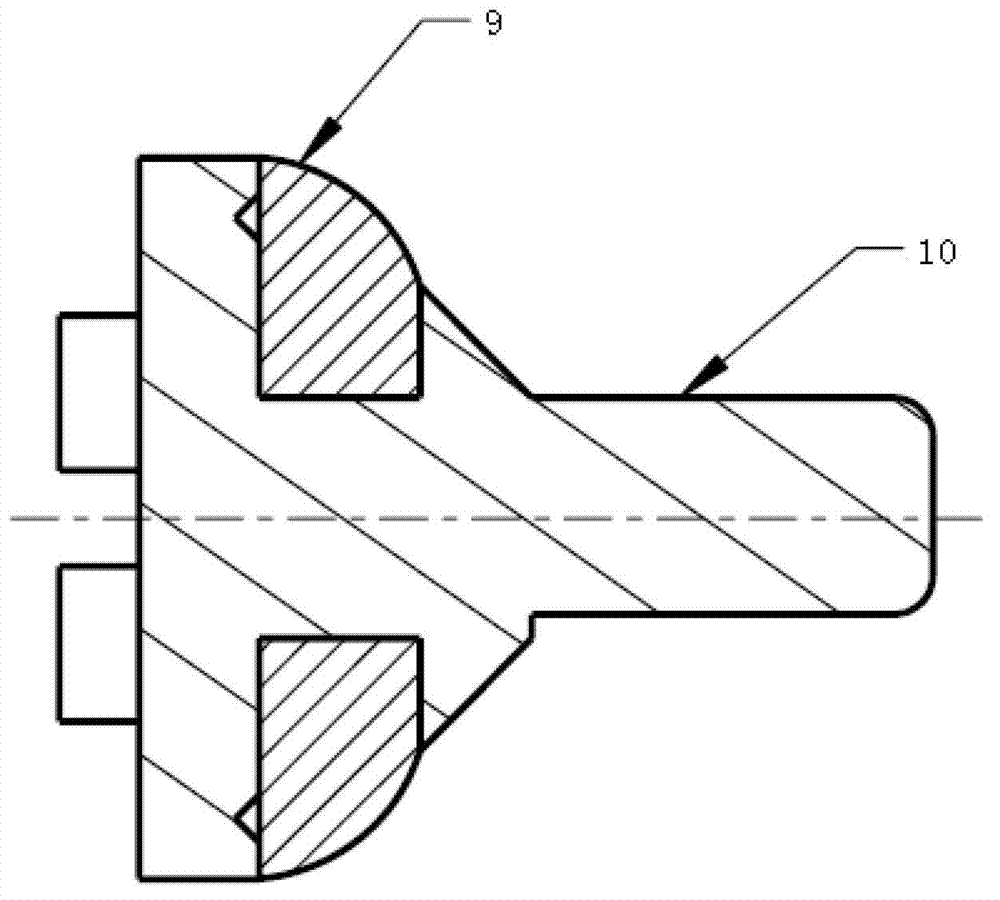

[0021] Such as figure 2 As shown, a new type of high-pressure inflation nozzle, including a one-way valve 1, a spring 2, a one-way valve core 3, a housing 4, a plug cap 5, a protective retaining ring 6, an "O"-shaped sealing ring 7, and an elastic stopper for the hole Ring 8, wherein the housing 4 is a hollow tubular body, the plug cap 5 is set on the right end of the housing 4, the check valve support 1, the spring 2 and the check valve core 3 are placed inside the housing 4, and the check valve support 1 is connected with check valve core 3 through spring 2.

[0022] In order to obtain better results, the above components can be selected as follows:

[0023] On the housing 4 at the contact surface between the housing 4 and the blocking cap 5, a protective retaining ring 6 and an "O"-shaped sealing ring 7 are arranged fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com