A solenoid valve for a compressor

A technology of compressors and solenoid valves, applied in valve details, valve devices, multi-way valves, etc., can solve problems such as short service life, unstable working performance, heavy kinetic energy of moving iron core 2′, etc., and achieve service life Long, stable and reliable working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

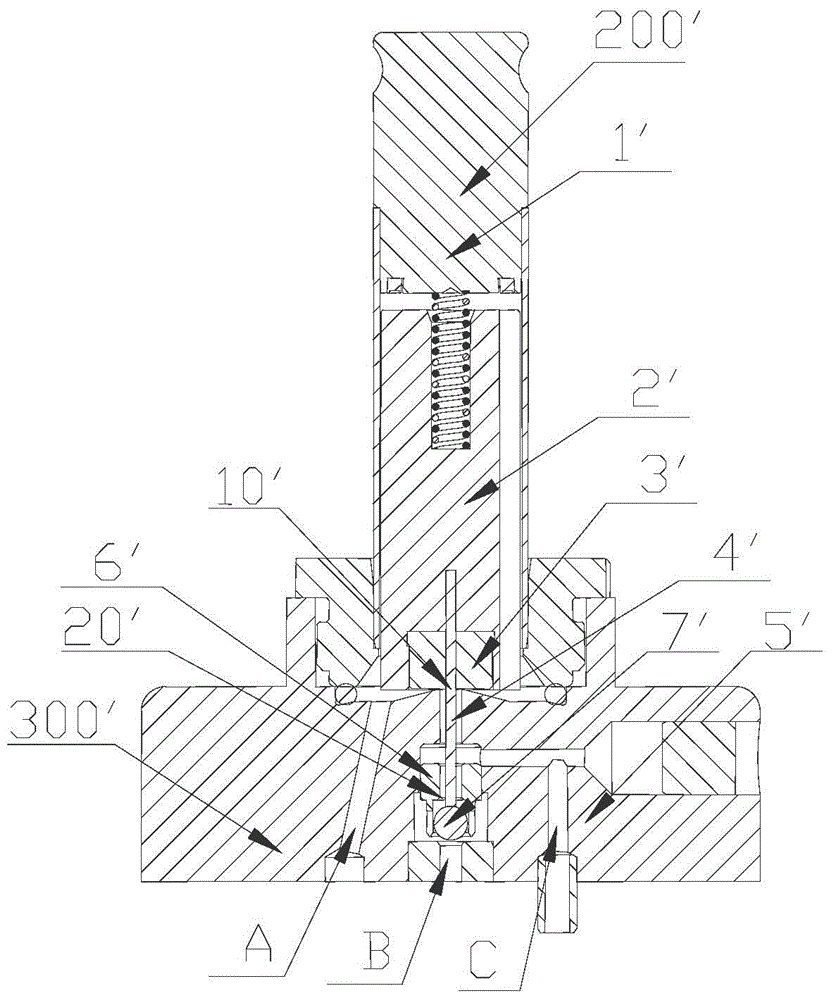

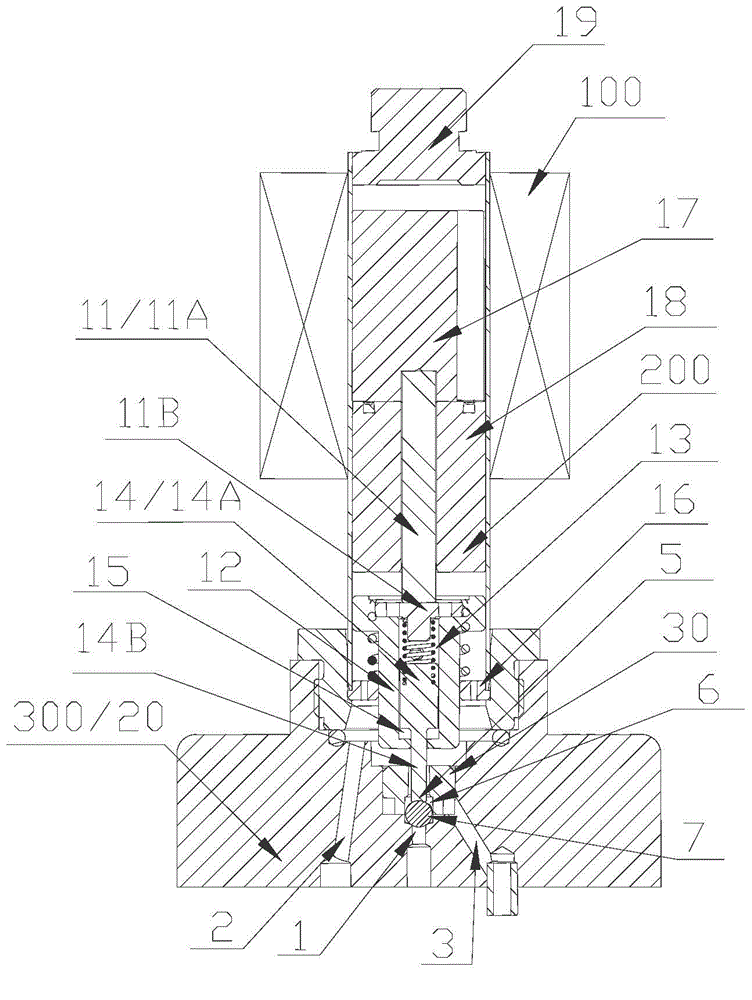

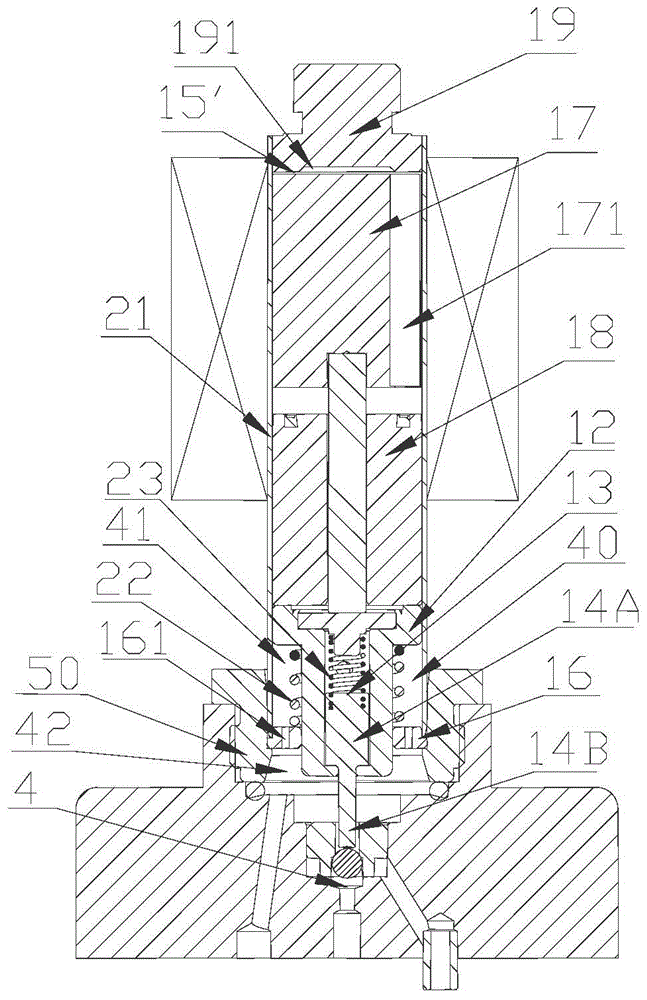

[0027] The structure and working principle of the solenoid valve for compressor of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] figure 2 Shown is a schematic structural view of a solenoid valve for a compressor according to a specific embodiment of the present invention under the condition that the coil part is energized; image 3 Shown is a schematic structural view of a solenoid valve for a compressor in a power-off state of a coil part according to a specific embodiment of the present invention; Figure 4 shown as figure 2 Schematic diagram of the transmission sleeve of the solenoid valve used in the medium compressor; Figure 5 shown as figure 2 Bottom view of auxiliary valve seat of solenoid valve for medium compressor.

[0029] Such as Figure 2 to Figure 5 As shown, the solenoid valve for a compressor in this embodiment includes a coil component 100 , a valve body component 200 and a valve seat c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com