Injector for a fuel injection system

An injection system and injector technology, applied in fuel injection devices, special fuel injection devices, charging systems, etc., can solve problems such as steep characteristic curves, and achieve the effects of avoiding manufacturing costs and increasing pressure areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

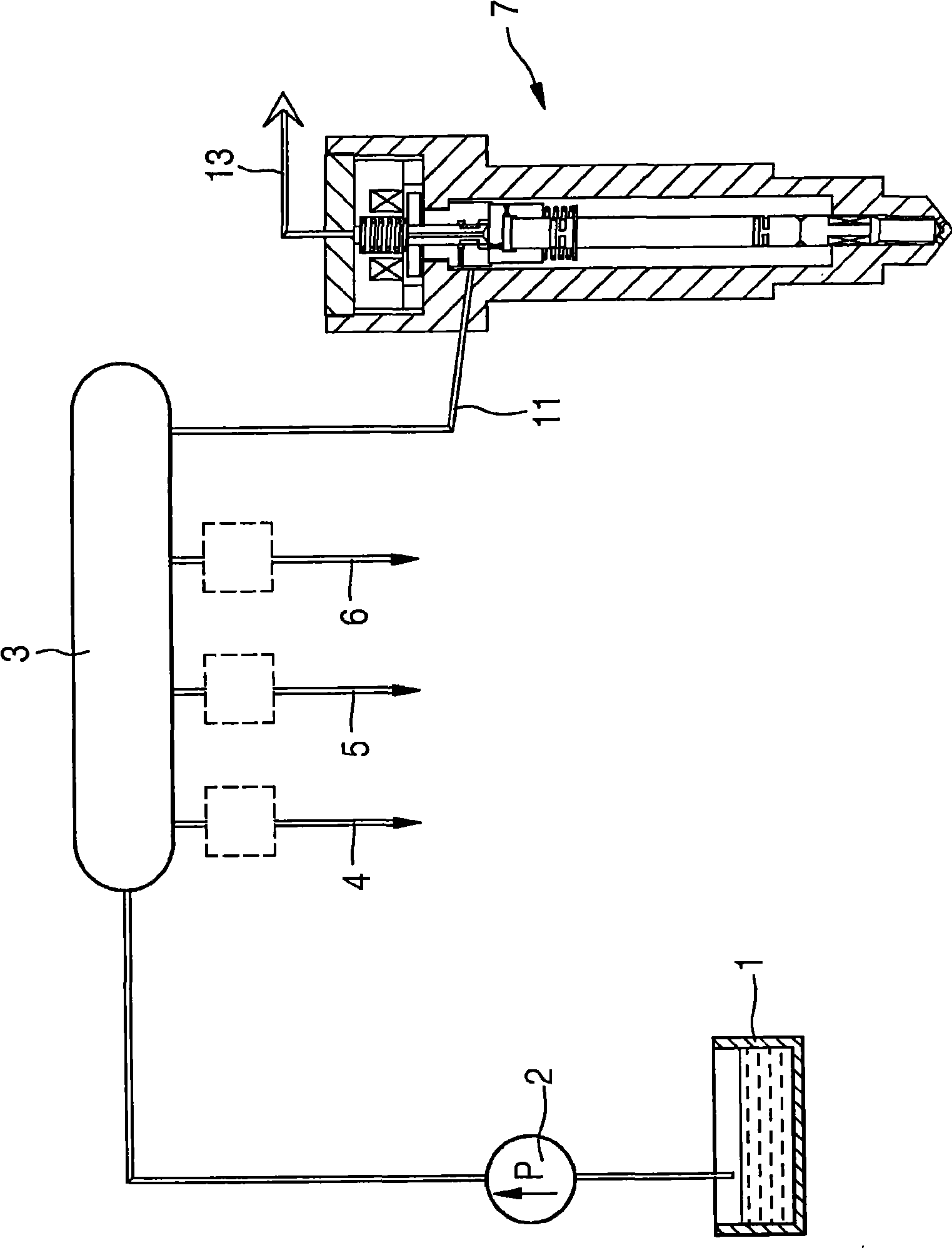

[0022] figure 1 A common rail injection system is schematically shown in . Fuel is delivered from a fuel tank 1 by means of a pump unit 2 to a high-pressure fuel accumulator 3 and is charged with high pressure. The fuel charged at high pressure is then distributed as required to the individual cylinders of the internal combustion engine to be supplied. Injection of high-pressure fuel takes place via injectors 4 , 5 , 6 and 7 . exist figure 1 Only the injector 7 is shown here for the sake of clarity.

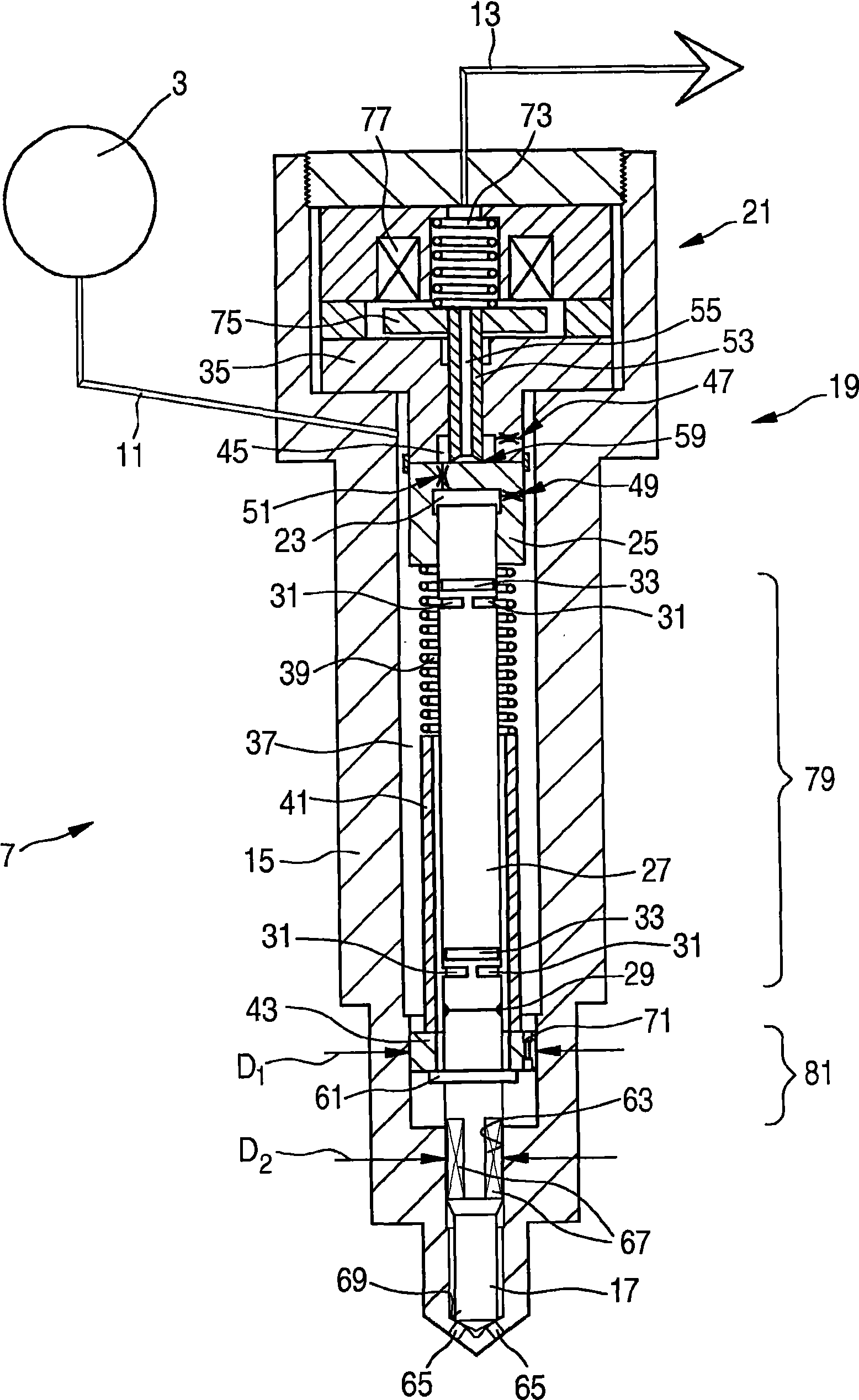

[0023] The injector 7 is connected to the common rail 3 via a high-pressure connection 11 . In addition, the injector 7 is hydraulically connected to the fuel tank 1 via an almost pressure-free fuel return line 13 . Below with the help of figure 2 with 3 The injector 7 is explained in detail.

[0024] The injector 7 includes a housing 15 in which a nozzle needle 17 is guided. A control valve 19 according to the invention and an electromagnetic actuator 21 are arranged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com