Shell assembling device and shell having the same

a technology of assembling device and shell, which is applied in the direction of mechanical equipment, furniture parts, couplings, etc., can solve the problems of high cost and stricter control of tolerance means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]These and other aspects, solutions and advantages of the invention will become apparent and more readily appreciated from the following descriptions taken in conjunction with the drawings, and the embodiments should be considered as an explanation instead of limitation to the invention.

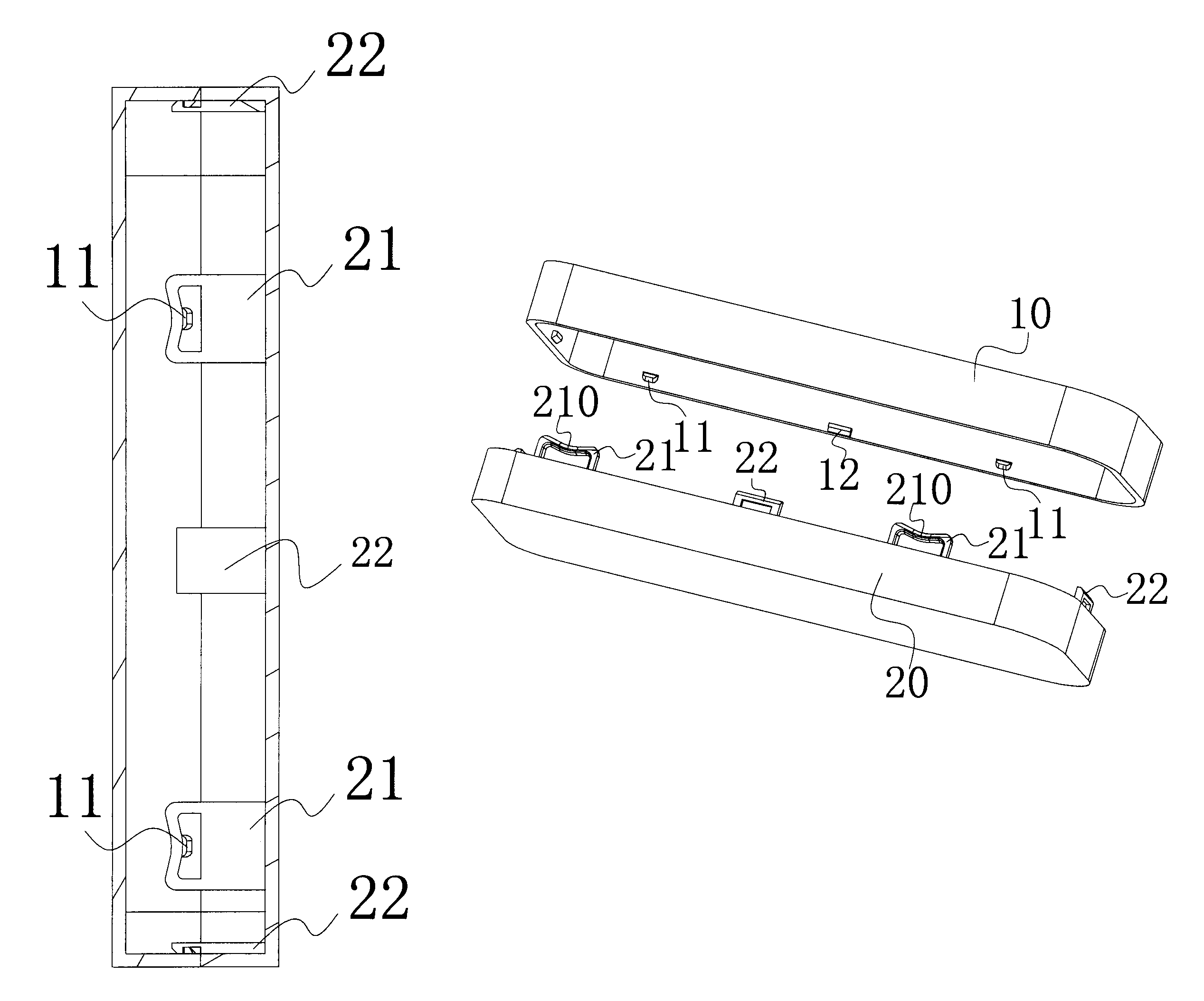

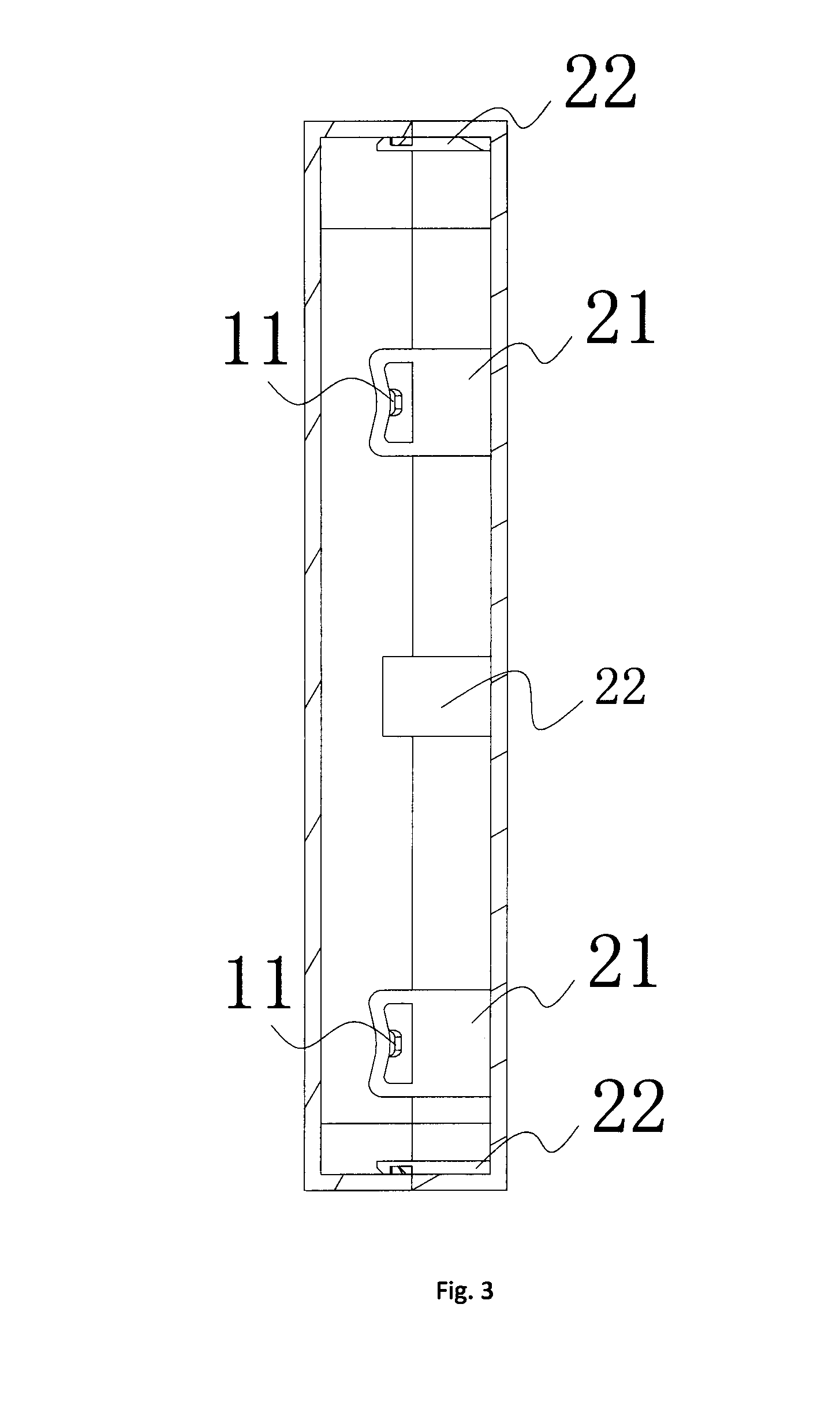

[0022]FIG. 1 to FIG. 6 shows a shell assembling device according to a first embodiment of the disclosure. The shell assembling device is used to assemble a first cover 10 and a second cover 20 so as to form a shell. The shell assembling device comprises a plurality of rigid fitting structures mounted on the first cover 10 and the second cover 20, and a plurality of elastic interference fitting structure mounted on the first cover 10 and the second cover 20.

[0023]In some embodiments, the rigid fitting structure is a rigid snap-in fitting structure, and comprises a rigid female button 22 disposed on the second cover 20 and a male boss 12 disposed on the first cover 10 and adapted to be snapped in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com