Universal joint

A power transmission and sliding shaft technology, applied in the field of universal joints, can solve problems such as increased clearance, reduce assembly clearance and noise, and improve strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A series of embodiments of the present invention and their corresponding drawings will be cited below for illustration. In the following description and drawings, the same reference numerals are used to represent the same or similar units, so the description of the same or similar units will not be repeated. Furthermore, detailed descriptions of known functions or structures are not repeated here to avoid obscuring the main subject of the present invention.

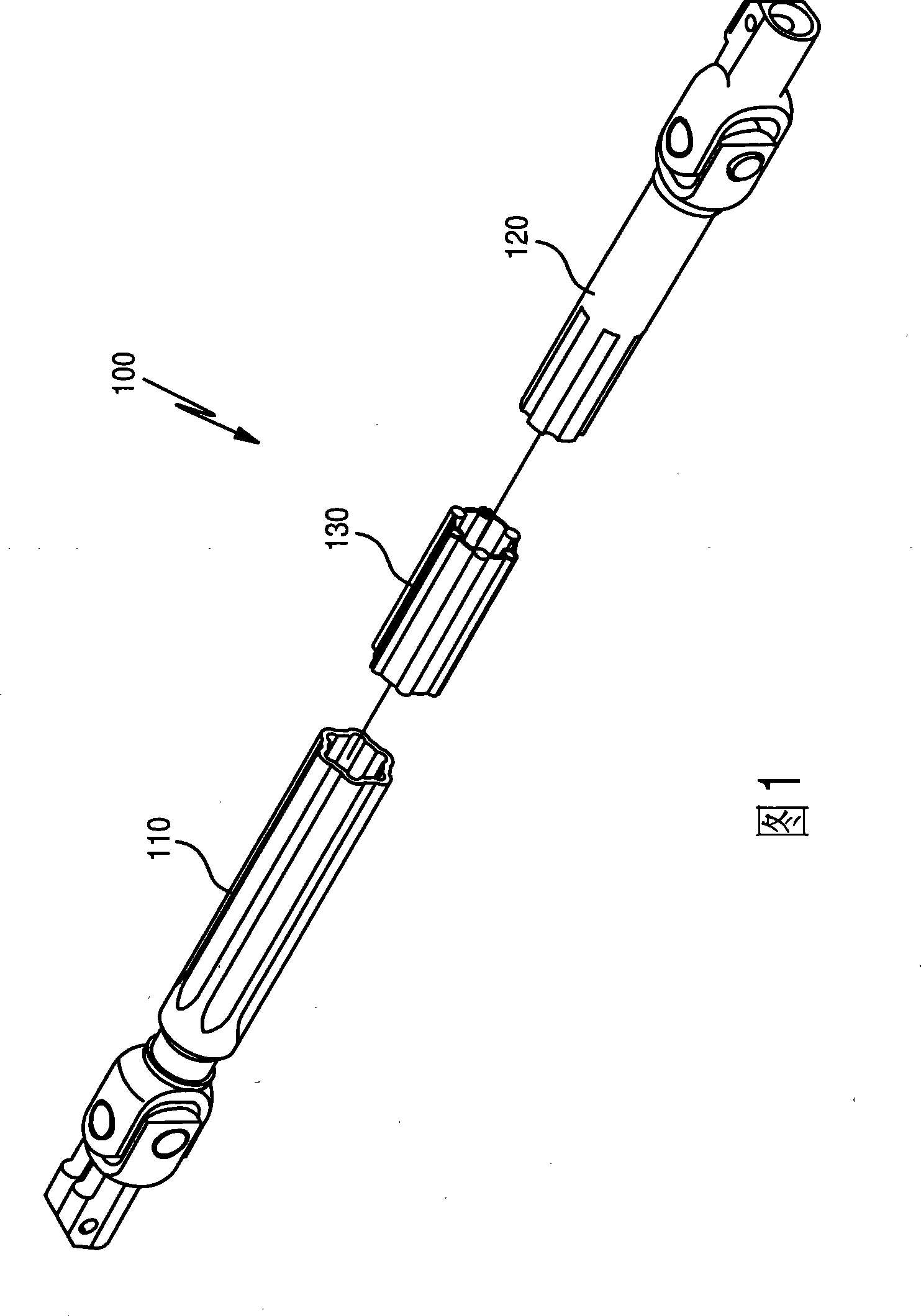

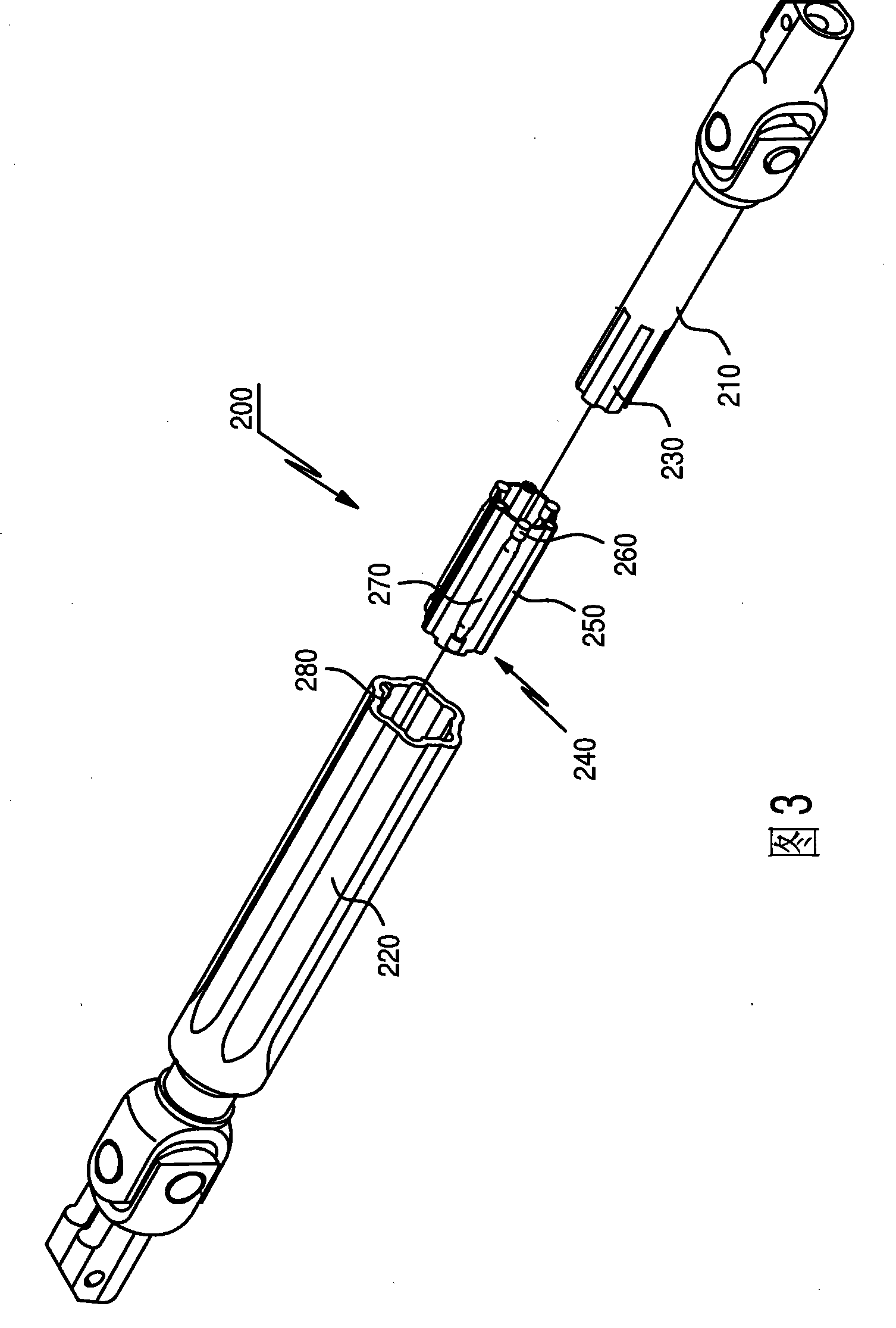

[0030] Fig. 3 is an exploded perspective view showing a universal joint according to a first embodiment of the present invention.

[0031] The universal joint 200 of the first embodiment of the present invention includes a shaft 210 inserted into a sliding bushing 240 , and a sleeve 220 which is hollow to accommodate the sliding bushing 240 inserted into the shaft 210 .

[0032] The shaft 210 has one end connected to a steering shaft (not shown), and the other end of the shaft 210 has a first combination recess 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com