Driving device

A driving device and a technology for installing shells, which are applied in the fields of windows and doors, can solve the problems of increasing the processing time of the transmission mechanism, difficulty in controlling the clearance of internal components, and the large space occupied by the transmission mechanism, so as to reduce the difficulty of installation and processing costs, and improve the installation efficiency. Effect of efficiency, small installation space requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

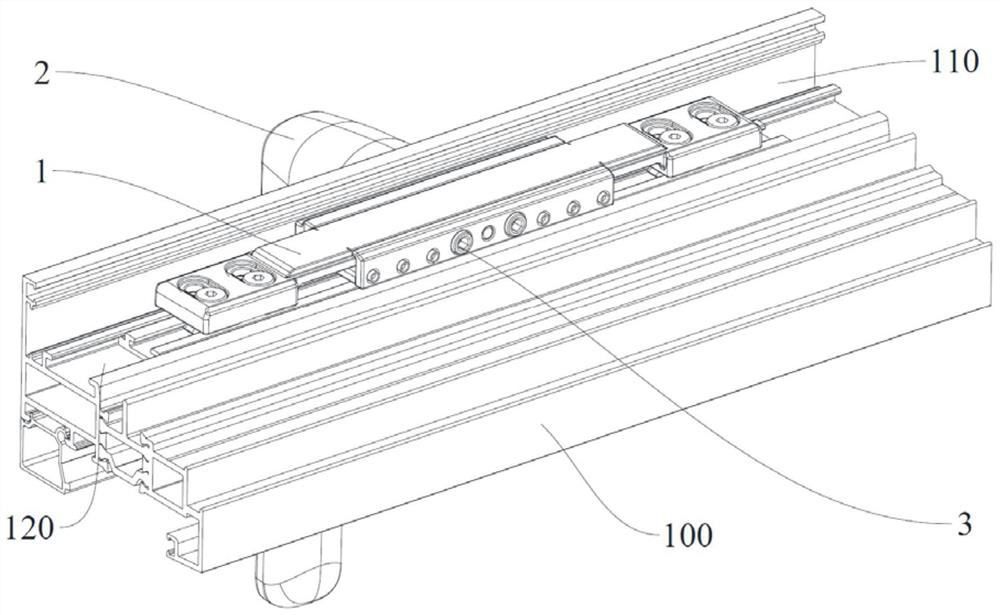

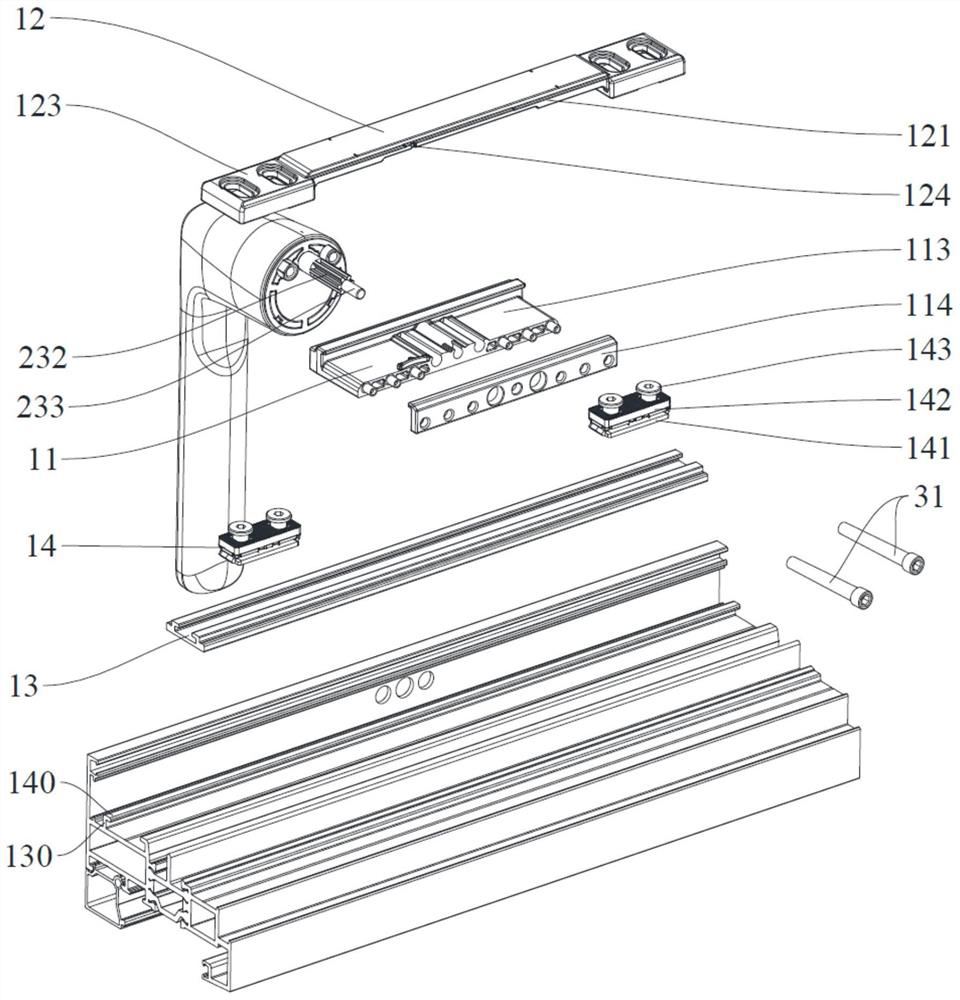

[0156] Refer below Figure 1-Figure 7 and Figure 14-Figure 21 A driving device of a specific embodiment of the present invention will be described.

[0157] The driving device in this embodiment includes a transmission mechanism 1 , a handle 2 and a locking mechanism 3 .

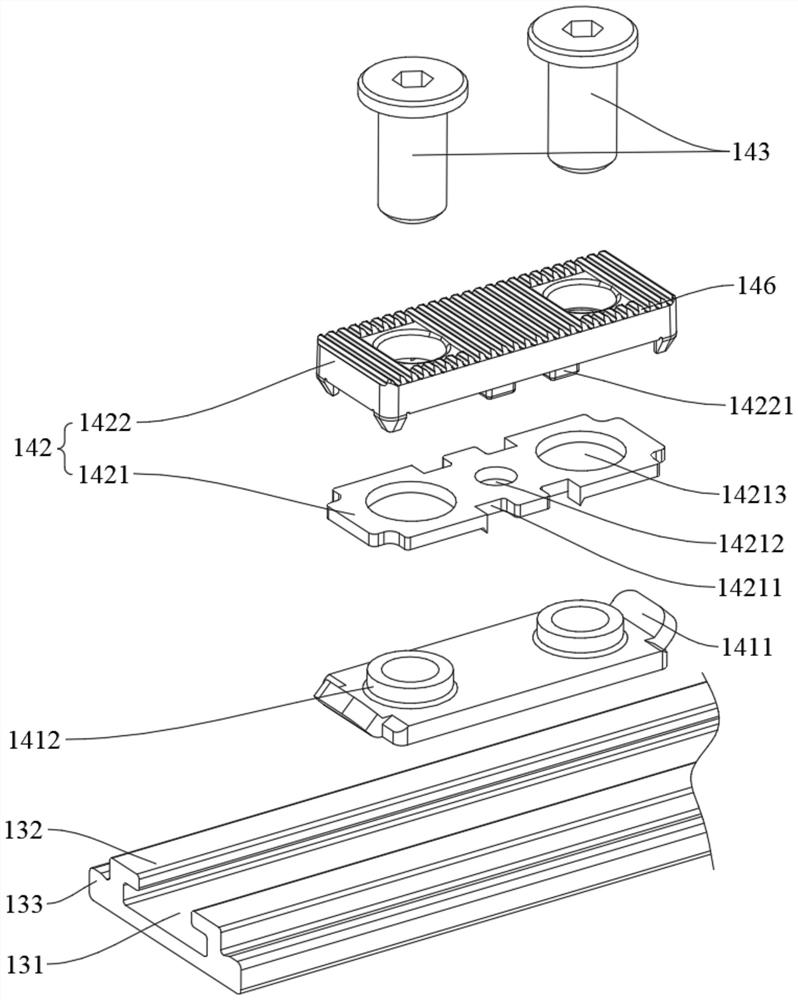

[0158] The transmission mechanism 1 includes a mounting shell 11, a movable part 12 and a connecting assembly 14. The side wall of the mounting shell 11 can be used to abut against the mounting wall 110 of the profile part 100, and the mounting shell 11 can be arranged on the profile part 100. The mounting shell 11 is formed with a sliding groove 111, and the tops of the two side walls of the sliding groove 111 are respectively provided with limiting edges 112, and the limiting edges 112 on the two side walls of the sliding groove 111 are respectively extended in the direction close to the other side wall . The movable part 12 is installed in the sliding groove 111, and the two side walls of the movable ...

Embodiment 2

[0169] The structure of the driving device of this embodiment is substantially the same as that of Embodiment 1. The difference between the two is the structure of the connecting assembly 14. Only the difference between the two is described here. The structure of this embodiment is the same as that of Embodiment 1. I won't repeat them here.

[0170] like Figure 8-Figure 12 As shown, the connecting assembly 14 includes a second connecting member 144 and a second fixing member 145 . A fastening protrusion 1443 is disposed on the bottom wall of the second connecting member 144 , and the fastening protrusion 1443 can be used to pass through the matching hole 135 on the transmission member 13 . The second fixing part 145 passes through the first connecting part 123 and connects with the second connecting part 144 . The second connecting member 144 includes a locking end 1441 and a connecting end 1442 . The locking end 1441 can be slidably locked in the profile part 100 . The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com