Cam-driven-type multi-station press transmission system

A multi-station press and transmission system technology, applied in the field of presses, can solve the problems of large assembly gap and poor machining accuracy of workpieces, and achieve the effect of eliminating assembly gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

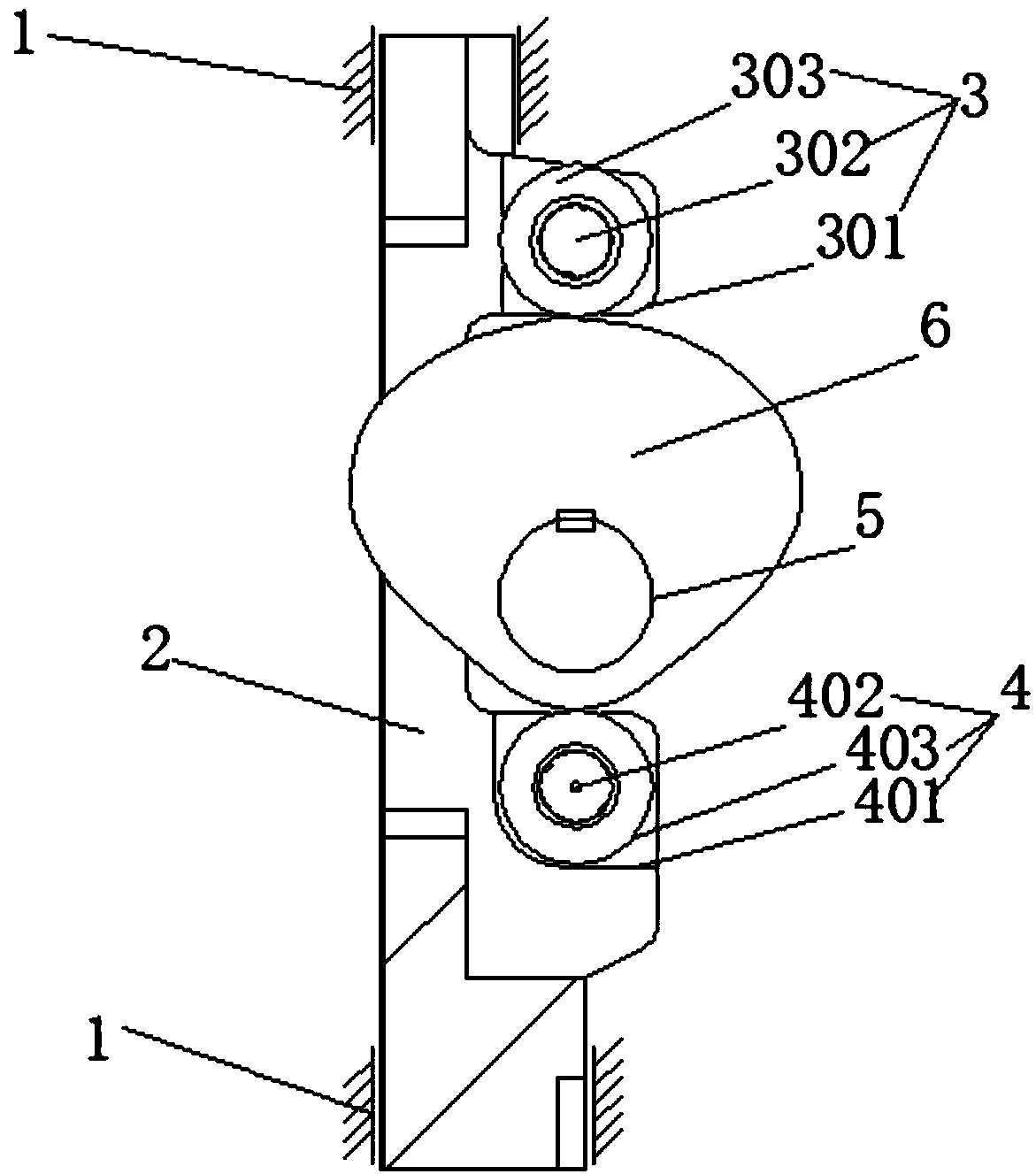

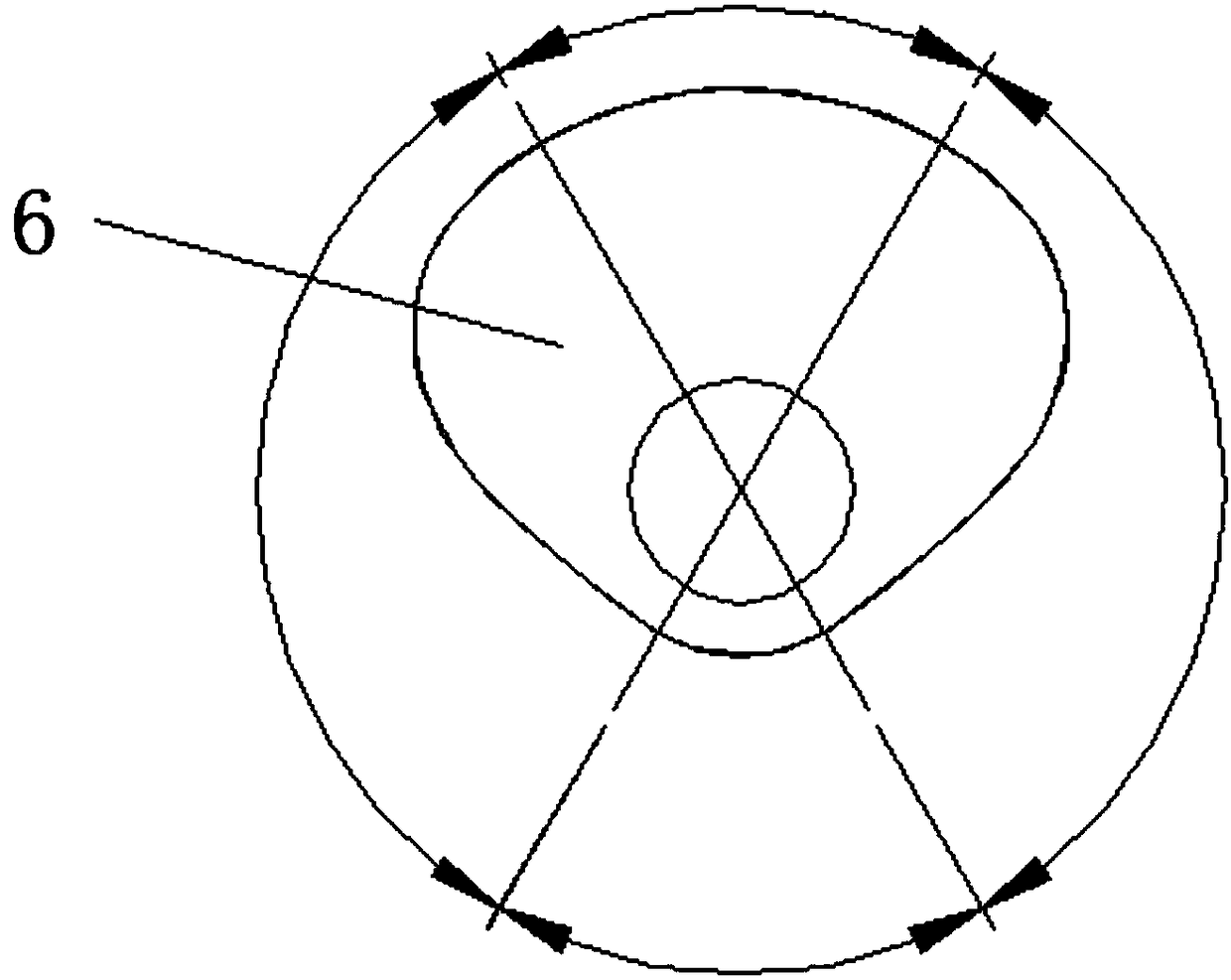

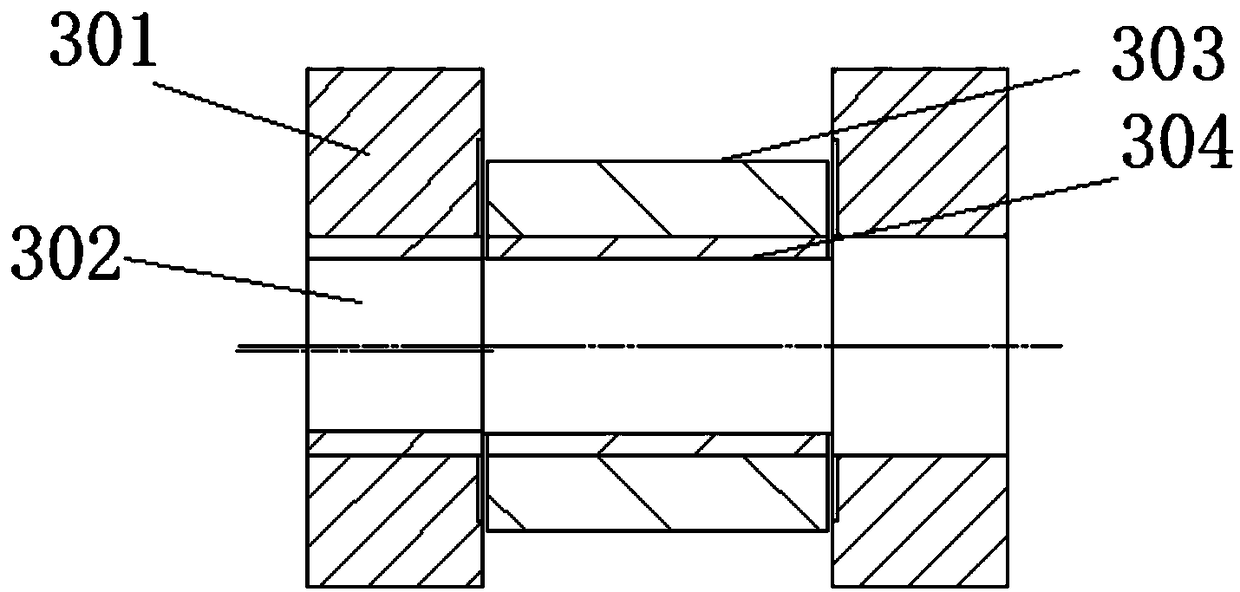

[0030] Such as Figure 1-2 As shown, a cam-driven multi-station press transmission system provided by the present invention includes a frame 1, a slider 2 and a main shaft 5, the slider 2 is slidably mounted on the frame 1, and the slider 2 The upper roller mechanism 3 and the lower roller mechanism 4 are installed at intervals, the main shaft 5 is installed on the frame 1, and the main cam 6 is installed on the main shaft 5, and the main shaft 5 is located at the upper roller mechanism 3 and the lower roller mechanism. 4, the main cam 6 is tangent to the upper roller mechanism 3 and the lower roller mechanism 4 respectively; the main shaft 5 and the main cam 6 in the present invention are used as power sources, and by promoting the upper roller mechanism 3 and the lower roller mechanism 4, it can The slider 2 moves up and down to realize the linear motion of the slider.

[0031] Wherein, the main shaft 5 is interference fit with the main cam 6, and the center of rotation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com