Sand mould used for casting machine tool double-arm vertical column casting and manufacturing method of sand mould

A dual-arm, casting technology, applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of difficult control of quality and dimensional accuracy, increased cleaning difficulty, and difficult control of size, so as to avoid the gap between core molds Insufficient tightness, avoiding loose positioning, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

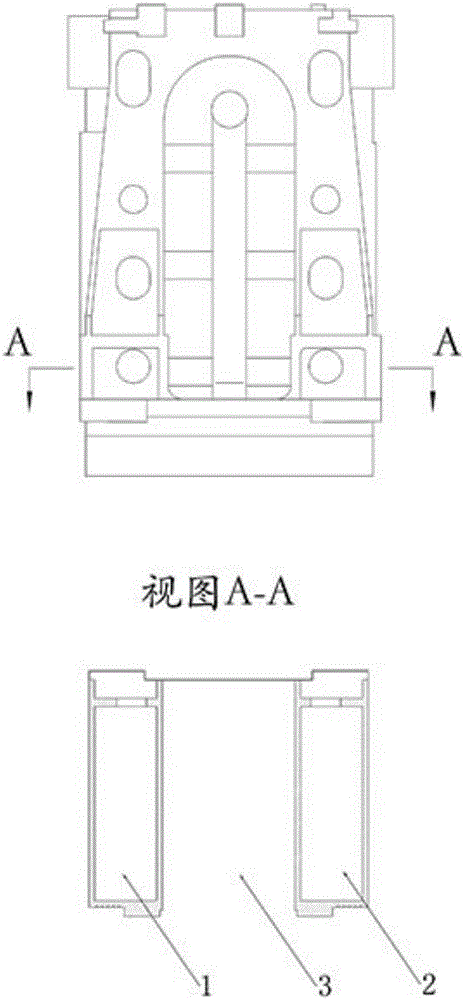

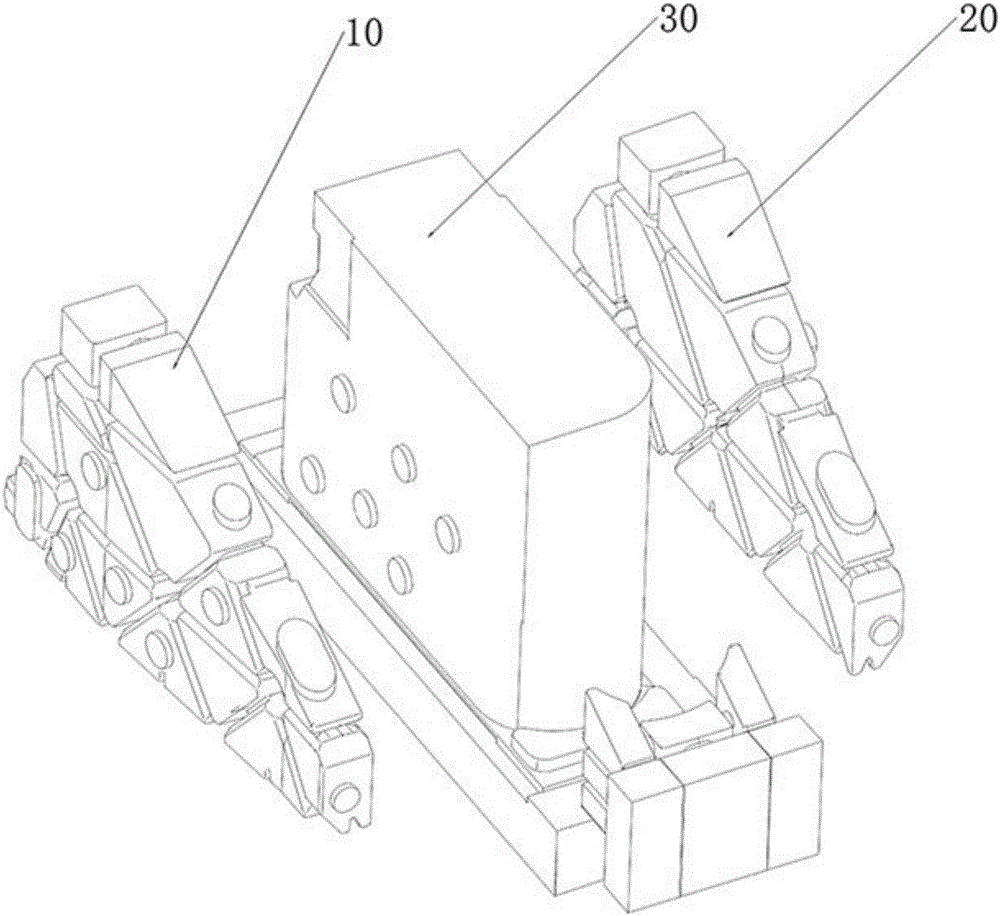

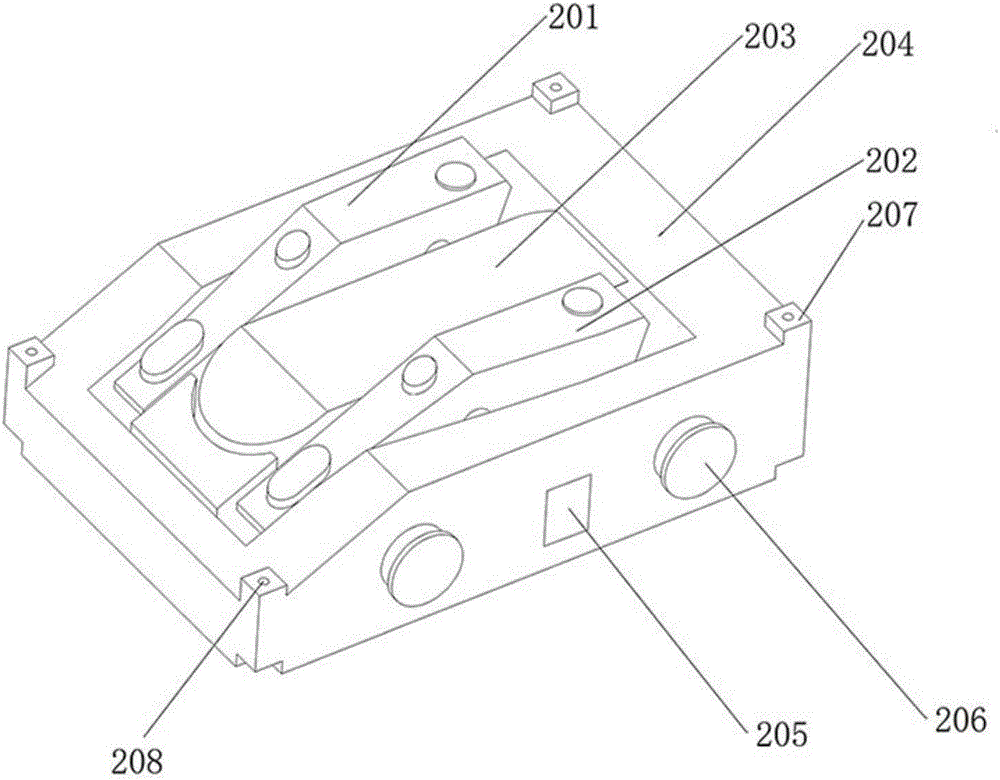

[0029] like image 3 As shown, one embodiment of the present invention provides a sand mold for casting double-arm column castings of machine tools, including a first mold unit 100 for forming the outer contour shape of the bottom of the double-arm column castings of machine tools, for forming double-arm column castings of machine tools. The second casting unit 200 of the inner cavity structure of the arm column casting, the outer profile of the side wall, and the outer profile of the facade is used to form the third casting unit 300 of the outer profile shape of the side wall, slope, and top surface of the double arm column casting of the machine tool.

[0030] like image 3 As shown, the second casting unit 200 is integrally formed by 3D printing and forming technology, and its structure includes a left arm forming part 201 for forming the inner cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com