Reinforced inner support structure for refrigeration compressor

A refrigeration compressor and support structure technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as increased clearance, unstable electrical air gaps in operation, and serious friction between rotor and stator parts. The effect of reducing electrical air gap, improving performance and reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

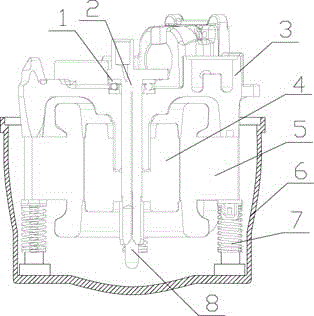

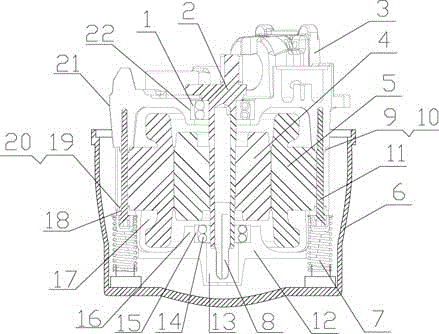

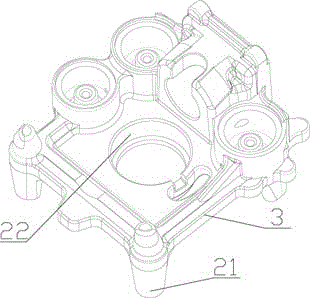

[0019] see figure 2 , a reinforced internal support structure of a refrigeration compressor in the present invention, including a housing 6, a stator 5 installed in the housing 6, a rotor 4, a cylinder block 3 installed above the stator 5, and a cylinder block 3 mounted on the rotor The crankshaft 2 between 4, the lower end of the crankshaft 2 is equipped with an oil suction pipe assembly 8, and the middle part of the cylinder block 3 is provided with a counterbore 22 to install the bearing A1 to form a rotational support for the upper end of the crankshaft 2, especially: a bracket is added below the stator 5 12. Left and right bolt holes 18 are provided on the bracket 12, and the bolt holes 18 on the bracket 12 and the bolt holes 18 on the stator 5 are threadedly connected with the cylinder block 3 through the bolt 11, and the bracket 12, the stator 5, the cylinder The seat 3 is installed as a whole; the middle part of the bracket 12 is provided with a boss 16, the upper par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com