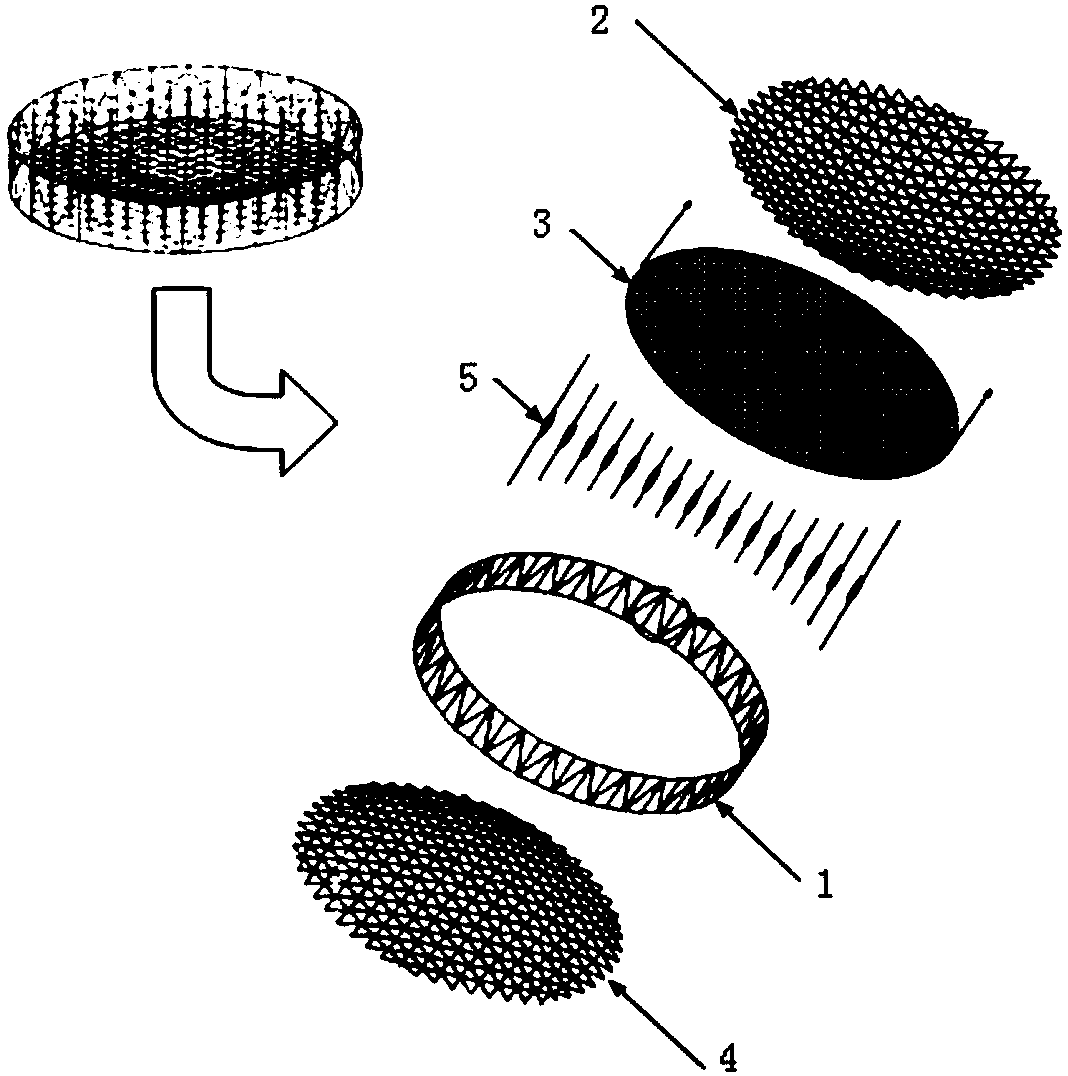

Mesh surface of spaceborne mesh antenna

A mesh and antenna technology, applied in antennas, antenna parts, antenna supports/mounting devices, etc., can solve the problems of not being able to meet the design requirements of high-precision mesh antennas, affecting the accuracy of antenna reflective surfaces, etc., to achieve small The effect of assembly clearance and high assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

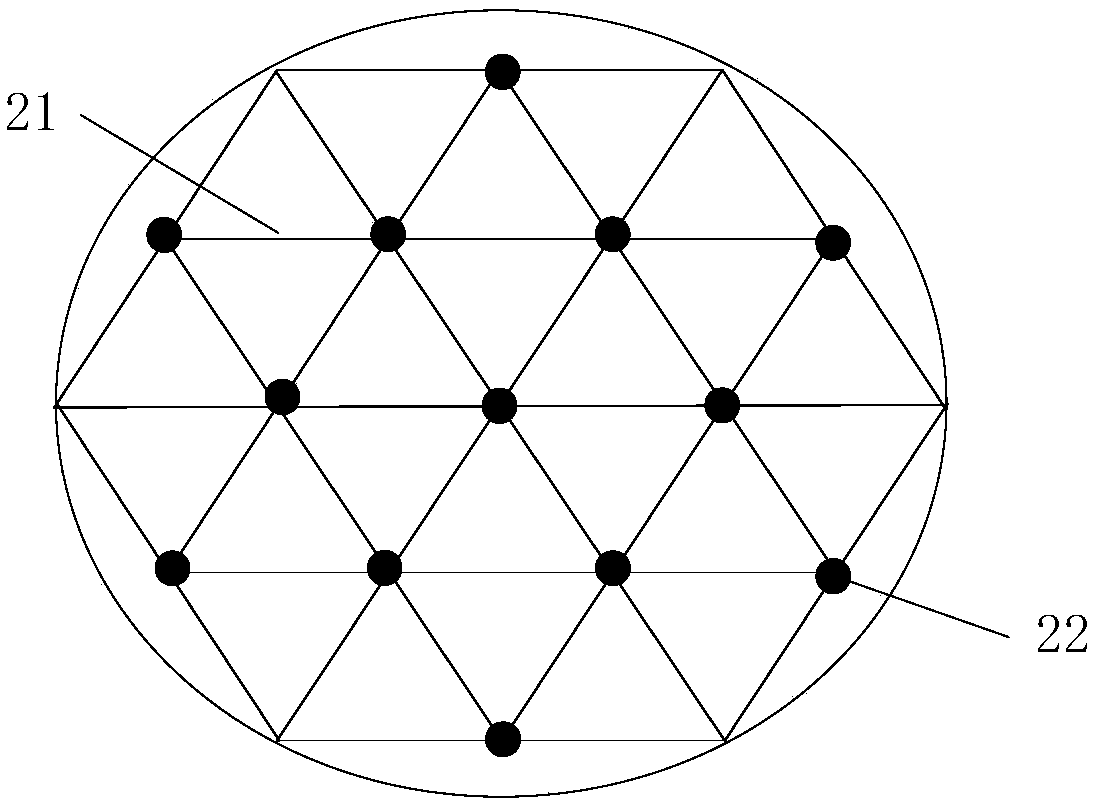

[0024] Take the mesh design of an elliptical loop antenna with a long axis of 7000mm and a short axis of 6000mm as an example. The mesh is a standard parabolic surface with a focal length of 3328mm and an offset of 4000mm. The number of segments on each side of the mesh is 16.

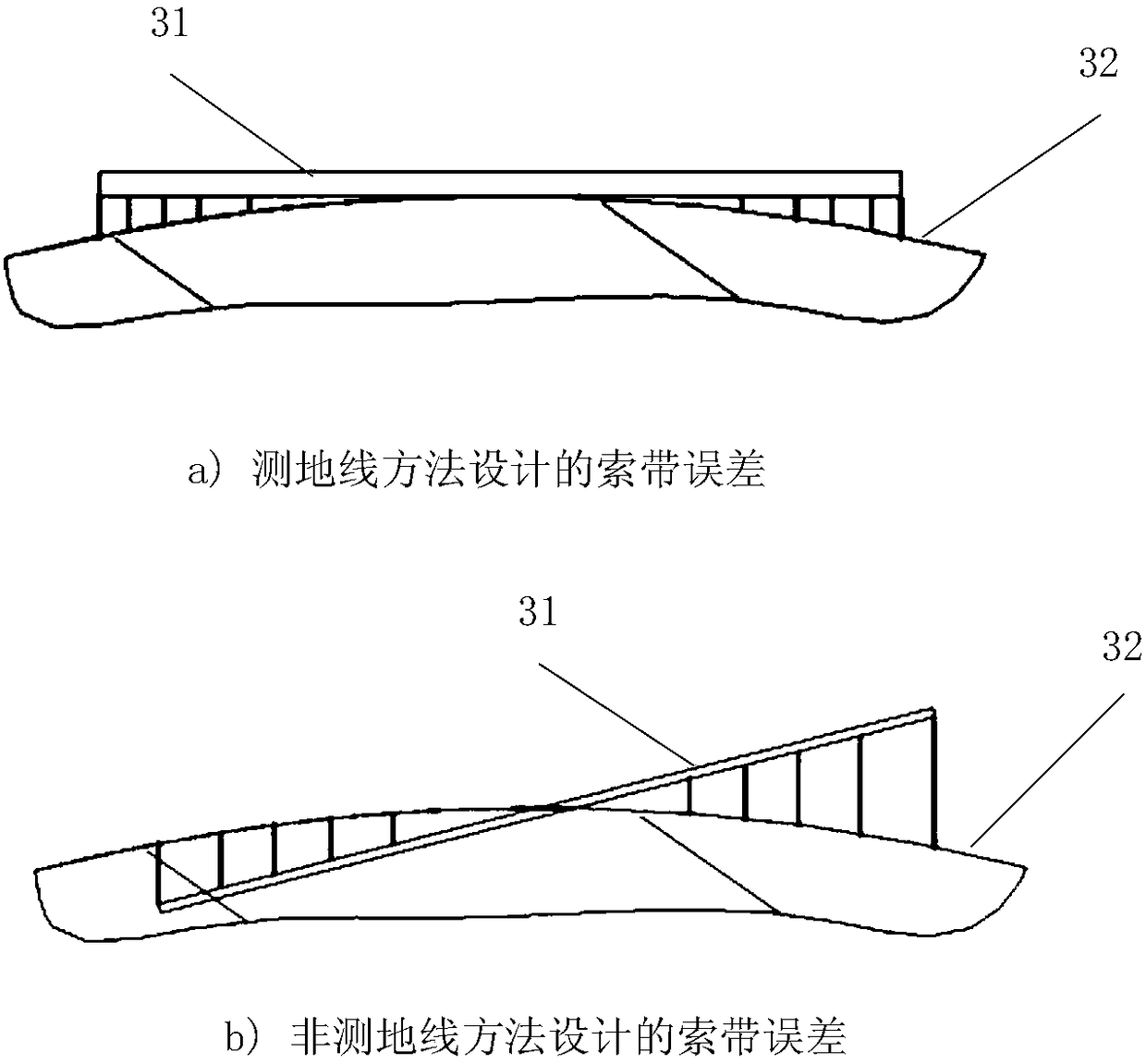

[0025] The present invention adopts the carbon fiber rope strap of rectangular section to replace the rope. Carbon fiber bundles are coated with polyimide to form high-rigidity carbon fiber tapes by hot-melt method. Through the optimized design of the size of the carbon fiber cable, the thickness of the carbon fiber cable is 0.25mm, and the width of the cable is 7mm.

[0026] Since the carbon fiber cable has a relatively high rigidity and a width of 7 mm, a row of unequal through-holes can be processed on the surface of the cable by CNC machining, and the diameter of the through-hole is generally related to the width of the cable. The diameter of the through hole in this example is 3 mm. The specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com