Housing case flanger and use method thereof

A technology of flanging machine and blower, which is applied in the field of flanging machine, which can solve the problems of poor roundness accuracy, expensive equipment, and affecting fan performance, and achieve the effect of small assembly clearance and improved aerodynamic performance and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

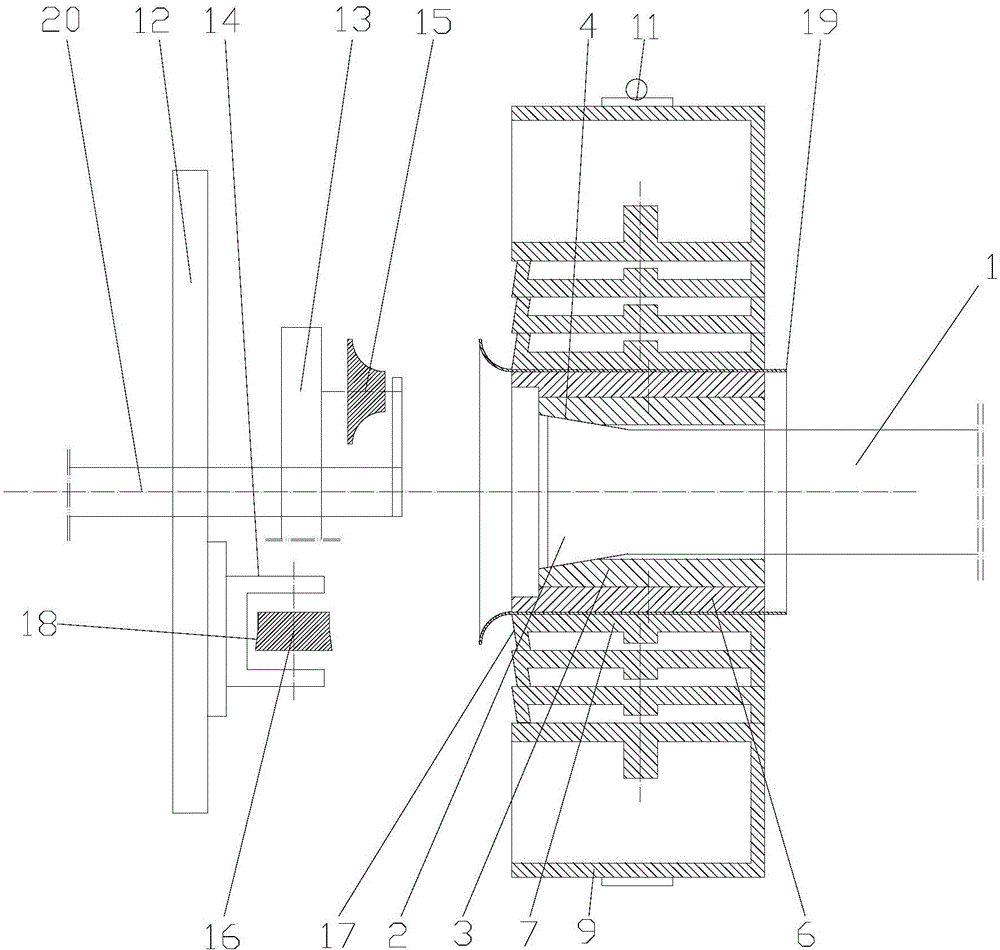

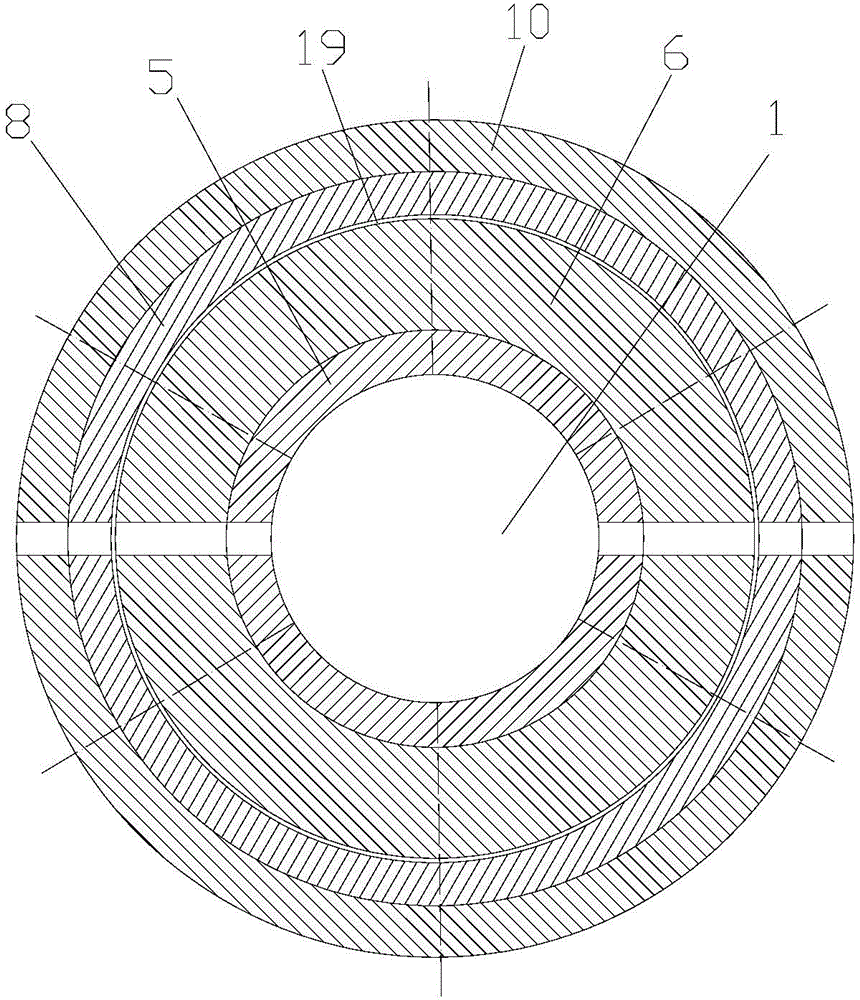

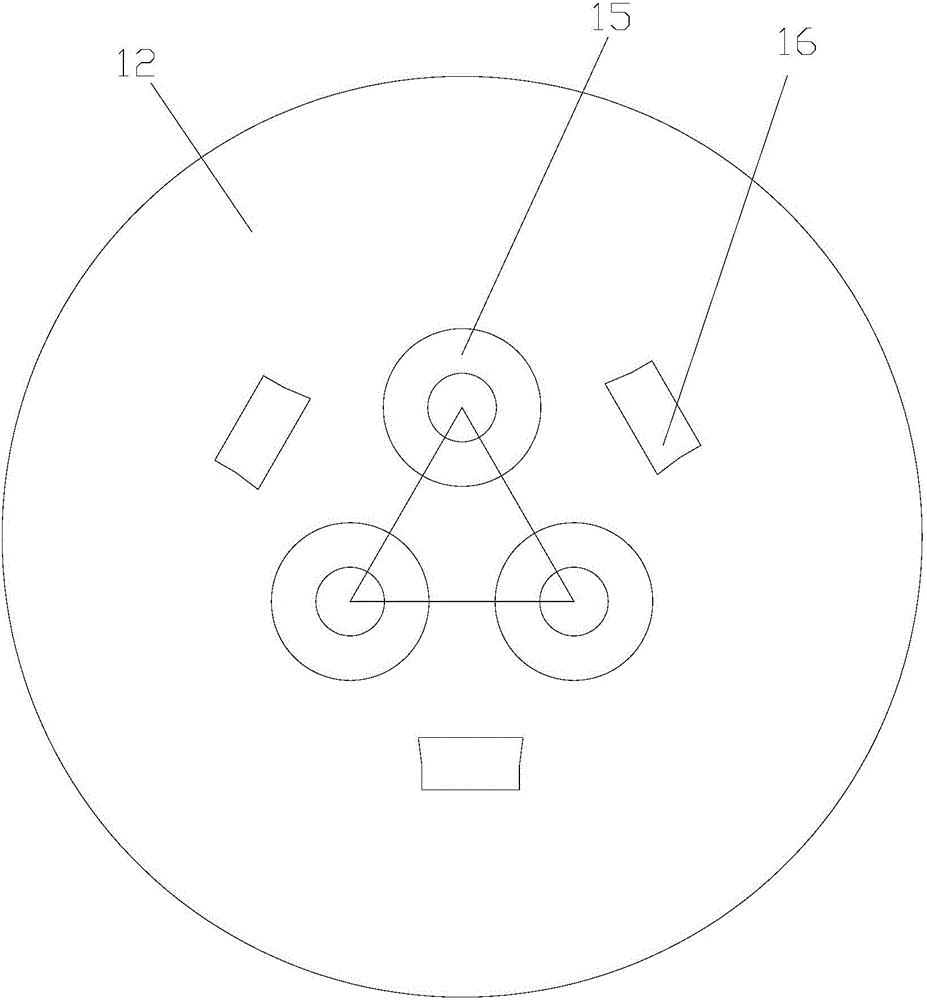

[0016] Such as figure 1 As shown, the present invention discloses a blower flanging machine, which includes an axial feed mechanism and a spindle box. In practical applications, the axial feed mechanism and the spindle box of the lathe can be utilized by refitting an existing ordinary lathe Box, the innovation point of the blower flanging machine according to the present invention is that it also includes a coaxially installed fixture device and a spinning device, the fixture device is fixed on the axial feed mechanism, and the spinning device The transmission is connected to the spindle box, and the spinning device can be driven to rotate axially through the spindle box. The fixture device includes a positioning shaft 1, and the end of the positioning shaft 1 facing one end of the spinning device has a truncated cone Body-shaped expansion chuck 2, the large end of the expansion chuck 2 faces the spinning device; the outer periphery of the positioning shaft 1 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com